Mold Your Success: Unleashing the Power of Injection Molder Services for Your Business

from web site

When it comes to shaping the success of your business, tapping into the realm of injection molder services can be a game-changer. The precision, efficiency, and versatility offered by injection molding technology have revolutionized various industries, offering a cost-effective and streamlined solution for producing high-quality parts and products. Whether you're in the manufacturing sector, automotive industry, healthcare field, or any other field requiring customized components, understanding the power of injection molder services is essential for staying competitive in today's market.

Benefits of Injection Molder Services

When considering the benefits of injection molder services for your business, one key advantage lies in the speed and efficiency of production. Injection molders are equipped to create high volumes of items in a relatively short time frame, allowing your business to meet demand and stay ahead of the competition.

Another significant benefit is the precision and consistency that injection molding offers. With advanced technology and precise control over the process, injection molder services can produce complex and detailed products with remarkable accuracy. This ensures that each item meets the exact specifications, leading to high-quality outcomes for your business.

Cost-effectiveness is yet another advantage of utilizing injection molder services. By optimizing material usage and minimizing waste, injection molding can help reduce manufacturing costs in the long run. Additionally, the efficiency of the process contributes to lower labor expenses, making it a cost-effective solution for businesses looking to scale their production while maintaining profitability.

Factors to Consider When Choosing an Injection Molder

Firstly, it is important to assess the experience and expertise of the injection molder. Look for a company that has a proven track record in providing high-quality services and has worked with a diverse range of industries. Experience often translates to efficiency and reliability in meeting the specific requirements of your business.

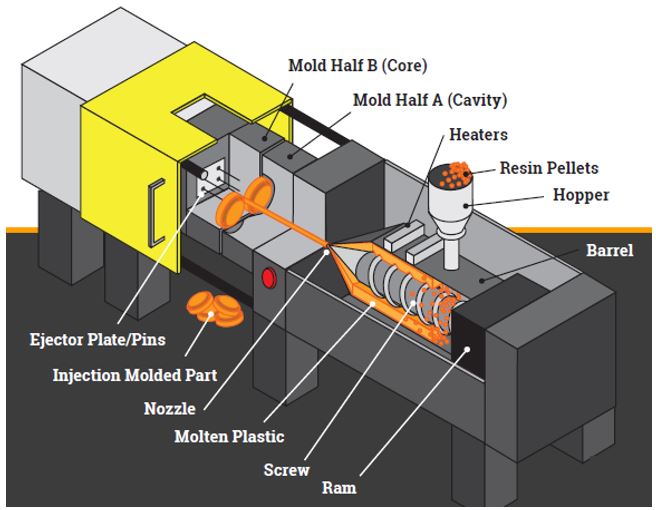

Secondly, evaluate the capabilities and equipment of the injection molder. Make sure that they have the necessary technology and machinery to handle the volume and complexity of your project. Having state-of-the-art equipment can lead to better precision, consistency, and overall quality in the manufacturing process.

Lastly, consider the location and communication of the injection molder. Opting for injection molds that is geographically convenient can help streamline logistics and reduce lead times. Effective communication is also key, as clear and prompt interactions can ensure that your needs are understood and met throughout the project timeline.

Maximizing Efficiency in Injection Molding Processes

When it comes to injection molder services, efficiency plays a crucial role in ensuring optimum productivity levels. One key aspect to consider for maximizing efficiency is the proper selection of materials. Utilizing high-quality materials that are well-suited for the specific injection molding process can significantly enhance the overall efficiency of the operation.

In addition to material selection, optimizing the design of the mold itself is essential for streamlining the injection molding process. A well-designed mold can minimize production time, reduce material waste, and improve the overall quality of the finished products. By investing in the design phase and ensuring the mold is properly engineered, businesses can achieve greater efficiency in their injection molding processes.

Furthermore, implementing a robust maintenance and monitoring system is critical for maintaining peak efficiency in injection molding operations. Regular maintenance of equipment and molds, coupled with real-time monitoring of process parameters, can help identify and address any potential issues proactively. By staying on top of maintenance and monitoring, businesses can prevent downtime, reduce costs, and maximize the efficiency of their injection molding processes.