A Insider Look at the Plastic Injection Forming Field

from web site

The plastic injection molding sector is a cornerstone of modern manufacturing, serving a crucial function in producing a wide range of household items to intricate auto components. As a fast and effective technique for producing top-notch plastic components, plastic injection molding service s have become essential for businesses looking to expand their manufacturing while upholding precision and uniformity. In this article, we will investigate the nuances of this field, analyzing the processes, technologies, and benefits that come with utilizing services for plastic injection molding.

Comprehending the landscape of injection molding of plastic is important for companies looking to create and optimize their production methods. This sector not only allows rapid modeling and mass production but also provides versatility in material selection and design capabilities. By exploring the processes behind injection molding of plastic, we will discover how it addresses diverse industrial needs and supports a broad range of uses across various sectors.

Overview of Synthetic Molding Molding

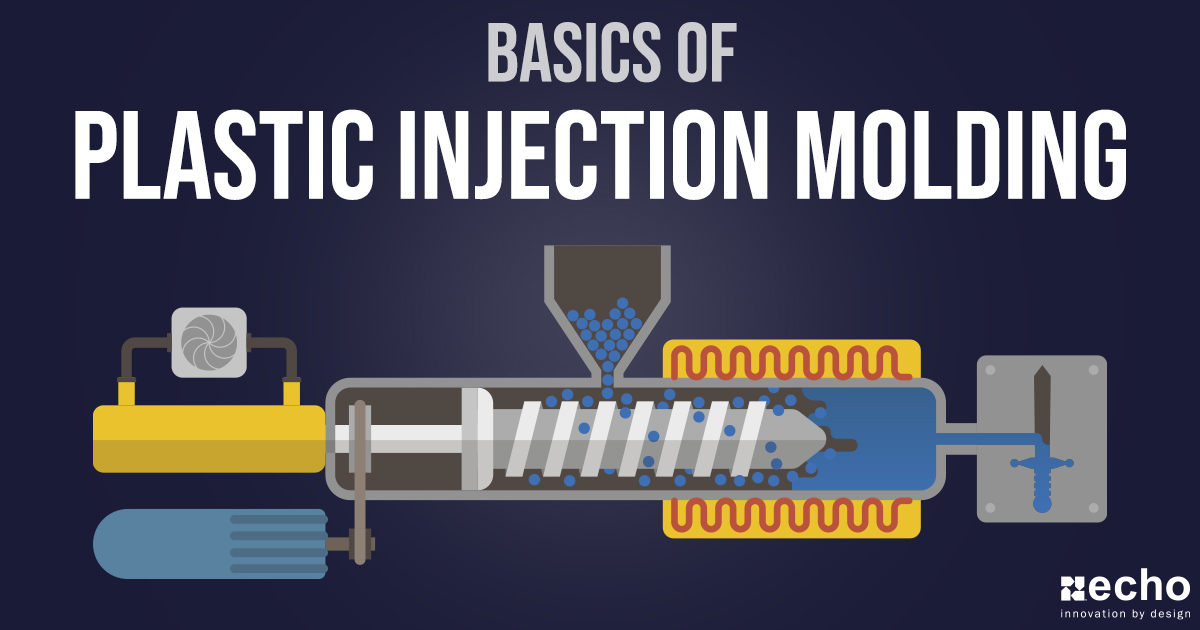

Synthetic injection formation is a production method used to produce plastic products by forcing liquid plastic into a form. This method is extremely effective and well-suited for producing massive volumes of uniform components. By heating synthetic substances until they become liquid and then injecting them into a precisely designed form, manufacturers can rapidly produce intricate designs with great accuracy. The outcome is a wide range of applications across different industries, including automotive, consumer products, and healthcare devices.

One of the main benefits of synthetic injection service is its ability to create intricate shapes that are often difficult or impossible to create with alternative manufacturing techniques. The method allows for the incorporation of different substances, colors, and finishes, providing producers with versatility in item design. Additionally, the quick cycle periods associated with plastic molding mean that items can be manufactured rapidly, meeting the demands of dynamic markets while ensuring quality control.

Additionally, the synthetic molding process is known for its affordability, especially as output scales up. The upfront investment in form development can be substantial, but the cost per item decreases substantially with higher production levels. This scalability makes injection formation an attractive choice for companies looking to optimize their production methods while maintaining uniform item standards. As innovation advances, developments in this industry persist to improve efficiency and open new possibilities for eco-friendly and environmentally friendly practices.

Primary Advantages of Plastic Injection Molding Services

Polymer injection molding services offer remarkable effectiveness in the manufacturing method. The technique allows for fast manufacturing of intricate shapes and patterns, making it perfect for high-volume production runs. With the ability to create multiple parts at once, companies can conserve time and reduce labor costs, enabling them to scale operations efficiently while keeping expenses in control.

One of the key advantages of these services is the ability to achieve high levels of accuracy and consistency. Injection molding produces parts with narrow margins, ensuring that each component meets the required standards. This level of accuracy reduces scrap and the need for extensive post-production post-production work, enhancing overall efficiency and quality control in production.

In addition, polymer injection molding solutions provide a significant level of design flexibility. Manufacturers can try out with different substances and colors to achieve desired aesthetics and utility. This versatility means businesses can innovate and modify their products to meet evolving industry needs, giving them a market advantage in an constantly changing business environment.

### Future Trends in the Plastic Injection Molding Industry

The plastic injection molding sector is set for major changes in the coming years, driven by advancements in technology and changing consumer preferences. One of the most notable trends is the integration of automation and robotics into production lines. Companies are progressively embracing automated solutions to boost efficiency, lower labor costs, and increase precision in molding. This shift not only boosts productivity but also enables quicker turnaround times for custom projects, catering to the fast-paced demands of various industries.

Another significant aspect is sustainability in the future of plastic injection molding. With increasing environmental awareness, businesses are pursuing environmentally friendly materials and methods. The use of biodegradable plastics and recycled materials is on the rise, allowing manufacturers to produce products with a lower carbon footprint. Additionally, the industry is exploring energy-efficient machinery and methods to minimize waste during production. Adopting these eco-friendly practices will comply with regulatory standards and appeal to consumers who are more environmentally conscious.

Finally, the emergence of additive manufacturing methods is expected to enhance conventional plastic injection molding. Hybrid processes that combine 3D printing with conventional molding can create complex geometries and customized components that were once difficult to produce. This flexible approach allows for innovative designs and rapid prototyping, enabling businesses to respond swiftly to market trends. As the field progresses, embracing these advanced technologies will be essential for firms striving to hold a competitive advantage in the worldwide market.