Exploring the Entry and Exit Milling Environment: Tips and Techniques

from web site

In the field of milling, the importance of a properly crafted entry and exit mill guide is paramount. These parts play a crucial role in maintaining accuracy and productivity during the machining process. Whether you're just starting with milling or aiming to improve your existing setup, understanding the best practices for this domain can greatly influence your results. From reducing mistakes to optimizing workflow, a tailored entry and exit mill guide can be a game-changer.

As technology evolves, so do the strategies and tools available to machinists. A exact entry and exit mill guide is essential for achieving the standard of exactness required in the modern challenging manufacturing environment. By mastering the nuances of these guides, you can enhance efficiency and produce superior components with certainty. In this discussion, we will look into practical tips and tricks to help you make the most of your entry and exit mill guides, guaranteeing your projects transpire seamlessly from inception to completion.

Grasping Entry and Exit Mill Fundamentals

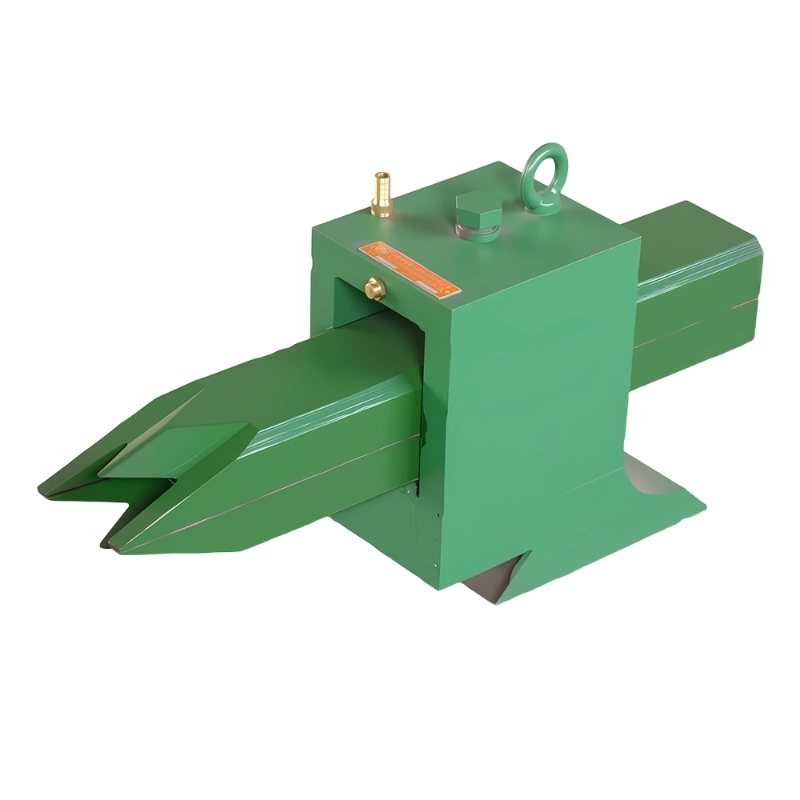

Entry and exit mills have a critical role in numerous machining operations, particularly in cutting and shaping operations. These tools are engineered to allow the exact insertion and removal of tools into and out of workpieces. Grasping their basics is vital for operators seeking to improve their machining skills. The configuration and functionality of these mills can significantly influence the quality of the finished product, making it essential to use the appropriate tools for the task.

One important aspect of inlet and outlet mills is their customization possibilities. Many modern mills can be customized to fit particular tasks, enabling for modifications in dimensions, cutting angles, and velocities. This adaptability not only improves accuracy but also boosts efficiency during manufacturing cycles. Users who take advantage of these modifiable options can achieve enhanced results and minimize waste of resources, ultimately maximizing their ROI.

Another crucial factor is the precision with which these mills operate. Precision entry and exit mills are engineered to keep tight tolerances, ensuring that cuts are made exactly where needed without deviation. This level of accuracy is particularly important in industries such as aviation and automotive, where even minor discrepancies can result in significant operational issues. By grasping the basics of inlet and outlet mills, operators can make educated decisions that result in improved efficiency and product quality.

Key Features of Adjustable Mill Guides

Adjustable mill guides are vital tools for ensuring efficient operation in milling processes. One of the standout features of these guides is their adjustable configurations. Users can modify the dimensions and settings to suit their specific milling requirements, allowing for increased flexibility in diverse applications. This adaptability makes it simpler to achieve targeted precision in the final product while catering to different materials and milling techniques.

Another notable aspect is the integration of easy-to-use interfaces. Precision Entry and Exit Mill Guide tailored mill guides come equipped with easy controls that streamline the adjustment process. This feature is particularly advantageous for operators who may not have profound technical expertise. By providing concise instructions and easy access to settings, these guides enhance the overall effectiveness of operations, reducing the chances for errors and increasing performance.

Strength is a crucial consideration in the design of adjustable mill guides. High-quality materials ensure that these tools can resist the rigors of continuous use in demanding environments. Furthermore, manufacturers often offer robust warranties, highlighting the longevity and reliability of their products. This emphasis on resilience guarantees that users can depend on their tailored mill guides for consistent performance over time, ultimately contributing to the efficiency of their milling processes.

Optimal Practices for Accurate Milling Methods

Attaining precision in milling necessitates a comprehensive understanding of the machine's functions and the material being processed. First, ensure that your tooling is in good condition and fit for the job. Worn tools can lead to irregularities in the machining process, affecting the final dimensions and surface finish. Regular maintenance of the milling tools, including proper lubrication and alignment checks, is crucial for maintaining accuracy and prolonging tool life.

Another key aspect of precision milling is the picking of suitable feeds and speeds. Each material has specific cutting parameters that optimize performance while minimizing wear on both the tool and the workpiece. Conducting evaluations and checking manufacturer guidelines can help determine the best settings for different applications. Staying alert to machine vibrations and adjusting parameters accordingly can also boost precision during the milling procedure.

Lastly, utilizing advanced software and technologies, such as CAD/CAM programs, can considerably upgrade the milling process. These tools allow for detailed designs and exact control over machining operations. By integrating adaptable options in the milling setup, operators can fine-tune processes to meet exact specifications, resulting in higher quality outputs. Committing in training and remaining current on the latest milling innovations will further aid in achieving precision reliably.