3D Printing Plastics Market Opportunities, Trends & Industry Analysis, Forecast 2030

from web site

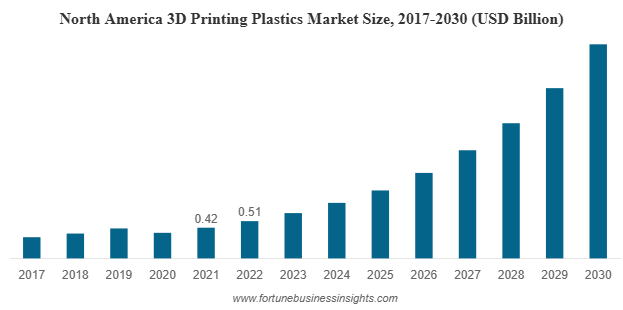

The global 3D printing plastics market was valued at USD 1.26 billion in 2022 and is expected to expand from USD 1.55 billion in 2023 to USD 7.46 billion by 2030, registering a strong CAGR of 25.1% over the forecast period. North America led the market in 2022 with a 40.48% share, while the U.S. market alone is anticipated to reach USD 2.71 billion by 2030, driven by rapid advancements in additive manufacturing and prototyping technologies.

Additive manufacturing, better known as 3D printing plastics market, has moved beyond its early days as a niche prototyping tool. Today, it is shaping how industries design, test, and manufacture products on demand. Among the wide range of materials used in this technology, plastics hold a crucial position. From aerospace to healthcare, 3D printing plastics market are transforming the way companies innovate and deliver solutions.

In recent years, the 3D printing plastics market has been experiencing remarkable growth. What was once valued at just over a billion dollars in 2022 is forecasted to multiply several times over by the end of this decade. With a compound annual growth rate exceeding 25.1%, the industry is expected to cross seven billion dollars by 2030. Such rapid expansion is being driven by material innovation, advances in printing technologies, and rising adoption across diverse sectors.

List Of Key Companies Profiled In 3d Printing Plastics Market:

- HP Development Company, L.P (U.S.)

- Evonik Industries AG. (Germany)

- Stratasys (U.S.)

- 3D Systems, Inc. (U.S.)

- Arkema S.A.(France)

- Henkel Corporation (Germany)

- EOS GmbH Electro Optical Systems (Germany)

- Solvay S.A.(Belgium)

- Huntsman Corporation (U.S.)

- SABIC (Saudi Arabia)

Why the Market Is Growing So Fast

- Innovation in Materials

One of the biggest factors pushing growth is the introduction of new plastic formulations designed specifically for 3D printing plastics market. Polylactic Acid (PLA), a biodegradable polymer derived from renewable resources such as corn starch, is gaining strong traction. It is not only eco-friendly but also easy to print, making it a preferred choice for beginners and professionals alike. Alongside PLA, other plastics such as ABS, polyamide, and polycarbonate are finding increasing demand due to their strength, flexibility, and durability.

- Technological Advancements

3D printing itself has seen major improvements in speed, resolution, and the ability to handle multiple materials and colors simultaneously. These advancements allow for the creation of complex geometries and high-performance components that were once impossible or too costly to manufacture using traditional methods. Better printers also mean faster turnaround times, which adds to the appeal of using plastics for both prototyping and end-use applications.

- Expanding End-User Applications

Industries are embracing 3D printing plastics market for very different reasons.

- Aerospace and defense companies are drawn to lightweight plastic components that reduce fuel consumption and overall costs.

- Healthcare is adopting these materials for customized implants, dental models, and patient-specific medical devices.

- Automotive manufacturers benefit from the ability to produce rapid prototypes and lightweight parts.

- Electronics and consumer goods industries use plastics for everything from functional components to creative product designs.

This diversity of applications ensures that demand is not concentrated in one sector but spread across multiple industries.

- Regional Expansion

North America currently leads the global market thanks to early adoption, technological expertise, and strong demand from aerospace and healthcare industries. However, Asia Pacific is emerging as the fastest-growing region. Countries such as China, India, Japan, and South Korea are investing heavily in additive manufacturing, supported by strong automotive, electronics, and consumer goods industries. Europe, too, continues to play a key role, driven by exports and advanced manufacturing systems.

Breaking Down the Market

The 3D printing plastics market can be segmented in several ways:

- By Material Type: PLA is the leading segment due to its eco-friendly nature and ease of use. ABS, polyamide, and polycarbonate also hold significant shares.

- By End-Use Industry: Aerospace and defense currently dominate the market, but healthcare is catching up quickly. Automotive, electronics, and consumer goods contribute steadily to overall demand.

- By Region: North America is the largest market, Asia Pacific is the fastest growing, and Europe continues to maintain a strong presence. Emerging markets in Latin America and the Middle East are also expected to expand gradually.

Read More : https://www.fortunebusinessinsights.com/3d-printing-plastics-market-108834

Opportunities for Businesses

For companies operating in this space, the growth trajectory offers immense opportunities. A few strategies stand out:

- Invest in R&D: There is room for breakthrough developments in material science. Plastics that combine multiple strengths—durability, lightness, sustainability, and affordability—will redefine the market.

- Focus on Compliance: Firms targeting aerospace or healthcare must be prepared for rigorous testing and certification processes. Building strong quality assurance systems will be key to long-term success.

- Strengthen Supply Chains: With global supply chains facing instability, localizing production and building partnerships for raw materials can provide resilience and cost advantages.

- Leverage Customization: 3D printing allows companies to offer tailor-made products with shorter lead times. Businesses that can capitalize on this demand for customization will stay ahead of the competition.

Key Industry Developments:

- March 2022: Evonik developed VESTAKEEP iC4800 3DF, a new osteoconductive PEEK filament that improves fusion between bone and implants. By developing this new filament, the company will further expand its portfolio of 3D-printable biomaterials for medical technology.

- March 2022: Evonik and Asiga, an Australian 3D printer manufacturer collaborated in photopolymer-based 3D printing. The companies aim to elevate the 3D printing industrial manufacturing at large-scale by increasing their competence in photo-curing technologies.

Challenges the Industry Faces

While the growth story is strong, the industry is not without its hurdles.

- Material Limitations: Developing plastics that meet all requirements—strength, heat resistance, flexibility, and biocompatibility—remains a challenge. Aerospace and medical industries, in particular, demand materials that can perform under extreme conditions.

- Certification and Regulation: Getting approval for 3D printed parts, especially in sensitive sectors such as healthcare and aerospace, involves stringent safety and quality checks. These add to costs and time before new materials or products can hit the market.

- Supply Chain Risks: Global disruptions in recent years have highlighted the vulnerability of raw material supply chains. Ensuring a steady and cost-effective supply of 3D printing plastics remains a critical concern.

Outlook

The future of the 3D printing plastics market looks bright. With projections crossing seven billion dollars by 2030 and applications expanding across industries, the sector is set for a dynamic decade. Growth in Asia Pacific, steady leadership in North America, and innovations across Europe will shape the global landscape.

Healthcare and aerospace are expected to deliver some of the most groundbreaking use-cases, especially as material limitations are overcome and regulatory hurdles are navigated. At the same time, eco-friendly materials such as PLA will become increasingly important as industries prioritize sustainability.

In short, 3D printing plastics market are not just materials for tomorrow they are already redefining how we create, customize, and consume products today.