The Backbone of High-Vacuum Systems: An Dive into Electronic Feedthroughs

from web site

In the realm of high-vacuum systems, one component stands out as a crucial factor in ensuring efficiency and functionality: the vacuum feedthrough. Such specialized devices serve as vital connections between the external environment and the internal structure of vacuum systems, allowing for the transfer of power and energy without compromising the vacuum seal. As industries ranging from semiconductor manufacturing to laboratory experiments increasingly depend on the precise conditions provided by vacuum environments, understanding the role of vacuum feedthroughs becomes necessary.

Electrical feedthroughs are designed to facilitate the reliable passage of electrical current while upholding the necessary low-pressure conditions within vacuum chambers. They come in multiple configurations, tailored to meet the particular requirements of various applications. Whether for running sensors, powering mechanical components, or facilitating data transmission, these feedthroughs play an crucial role in the success of vacuum technologies. In this article, we will delve into the nuances of vacuum electrical feedthroughs, exploring their structures, capabilities, and significance in the wider context of vacuum systems.

Types of Electrical Connectors

Electromagnetic connectors can be classified based on their design and application, with each type serving specific functions in high-vacuum systems. The most common types include single pin connectors, multi-pin connectors, and coaxial connectors. Single-pin feedthroughs are manufactured for simple connections, allowing a single connection from the external environment into the chamber. They are often used when just one electrical connection is necessary, making them a cost-effective and simple option.

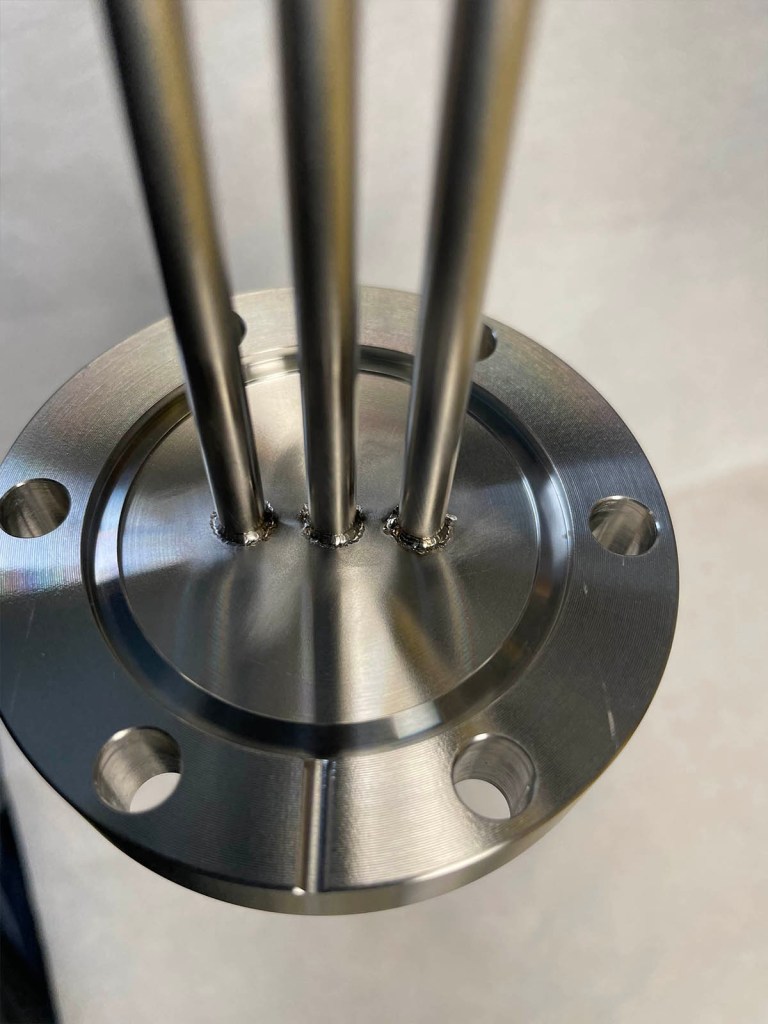

Multi-pin connectors, as the name suggests, incorporate several pins in a one feedthrough unit. This configuration enables multiple links at once, accommodating further complex systems requiring various electrical signals. Multi-pin feedthroughs are especially beneficial in applications such as sensor integration, where various signals from multiple sensors need to be transmitted to the controllers beyond the vacuum environment.

Coaxial type connectors give a specialized option for high-frequency applications or where electromagnetic interference is a concern. These connectors consist of a central conductor surrounded by an insulator and an external conductor, creating a shield. This design allows for efficient transmission of high frequency signals while reducing interference and interference. Coaxial connectors are commonly used in scientific research and state-of-the-art technological applications, ensuring reliable communication inside vacuum systems.

Design Considerations

When creating vacuum electrical feedthroughs, it is vital to consider the materials used. The decision of components is critical as they must endure high vacuum conditions while preserving electrical insulation and conductivity. Common materials include ceramics and high purity metals, which offer low outgassing rates and stability under different temperature conditions. Ensuring compatibility with the vacuum environment is paramount to ensure sustained reliability and performance.

Another key aspect of design is the configuration of the feedthrough itself. The layout needs to provide efficient electrical connections while minimizing the risk of contamination. Reducing the number of joints and seals can help achieve better vacuum integrity. Additionally, the feedthrough should be designed to accommodate thermal expansion and mechanical stresses that may happen during operation to stop failure over time.

Finally, safety and compliance with industry standards must be a main focus during the design process. This requires adhering to regulations related to electrical systems and vacuum technology. Proper testing and validation of the feedthrough design are also necessary to ensure it can handle the required electrical loads and operate effectively in a vacuum environment, which ultimately contributes to the overall effectiveness and safety of high-vacuum systems.

Uses in Vacuum Environments

Vacuum feedthroughs play a vital role in numerous high-vacuum applications, confirming that power signals and energy can be delivered without jeopardizing the vacuum environment. One prominent application is in electron microscopy microscopes, where exact control of electron streams is crucial. The feedthroughs allow for the necessary electrical connections to the microscope's components, allowing high-resolution imaging by maintaining an ultra-clean vacuum.

In the field of semiconductor manufacturing, vacuum feedthroughs are crucial for processes like thin-film application and etch processes. These processes require high precision and control over the vacuum levels to guarantee product integrity. The feedthroughs efficiently connect the required sensors and actuators within the vacuum chamber, enabling the accurate manipulation of materials while maintaining an acceptable environment clear of contaminants.

Another crucial application is in nuclear fusion research, where vacuum feedthroughs are used in tokamaks and other plasma confinement devices. These systems demand a secure and high-quality vacuum to support critical conditions for fusion reactions. The feedthroughs provide trustworthy electrical connections to measurement devices and control systems, allowing researchers to monitor and adjust conditions within the vacuum chamber, thus advancing the development of fusion energy technologies.