An Detailed Look into Electrical Feedthroughs in Vacuum Systems: Function and Construction

from web site

Vacuum-powered electrical connections are vital parts in numerous scientific and industrial fields in which the stability of a vacuum environment needs to be maintained while permitting electrical connections. These tailored units enable the movement of electrical signals and energy into and out of a vacuum aiding diverse activities in fields such as chip production, high-energy particle physics, and aerospace investigation. Comprehending these function and design is important for anyone involved in systems that require precise management and monitoring under vacuum.

At the core, vacuum feedthroughs make certain that the vacuum is not compromised during establishing an electrical connection. This capability is especially important vital in cases in which even minor contamination from outside the vacuum chamber can substantially affect performance. The design for such feedthroughs are many and can vary depending on criteria such as the degree of the required vacuum, the electrical energy levels, and the specific materials employed for fabrication. By delving into the intricacies of vacuum devices, we can gain insight into the technological advancements that is involved in preserving the fragile equilibrium between electric operation and a vacuum environment.

## Overview of Vacuum-based Electric Connections

Vacuum-type electrical connections represent crucial components used in various applications in situations where electrical links must be established across a vacuum barrier medium. These components allow the transfer of electrical signals and power from the external environment into a sealed chamber, maintaining that the integrity of the vacuum conditions is preserved. Generally located in research investigations, electronics manufacturing, and sealed environments, these interfaces serve an important function in the functionality and performance of equipment functioning in a vacuum chamber.

The engineering of vacuum-based interfaces requires careful attention of substances and construction methods to ensure stability and functionality. These devices are often composed from conducting materials that can endure the specific conditions of the vacuum while stopping any gas loss. Dielectric elements are also used to maintain the required electric barrier and avoid cross currents between different conductor routes. Innovative design methods are employed to optimize their configuration, taking into account considerations such as heat transmission, electrical resistance, and structural integrity.

One of the primary advantages of vacuum electrical feedthroughs is their capability to offer a smooth connection which keeps the vacuum state necessary for delicate processes. This is vital in uses like particle accelerators and electron imaging systems, in which even the slightest interference can greatly alter the results. By enabling secure and productive electrical interfaces in hermetic environments, these components play a role to the development of technological innovation and scientific investigation in multiple areas.

Key Components and Materials

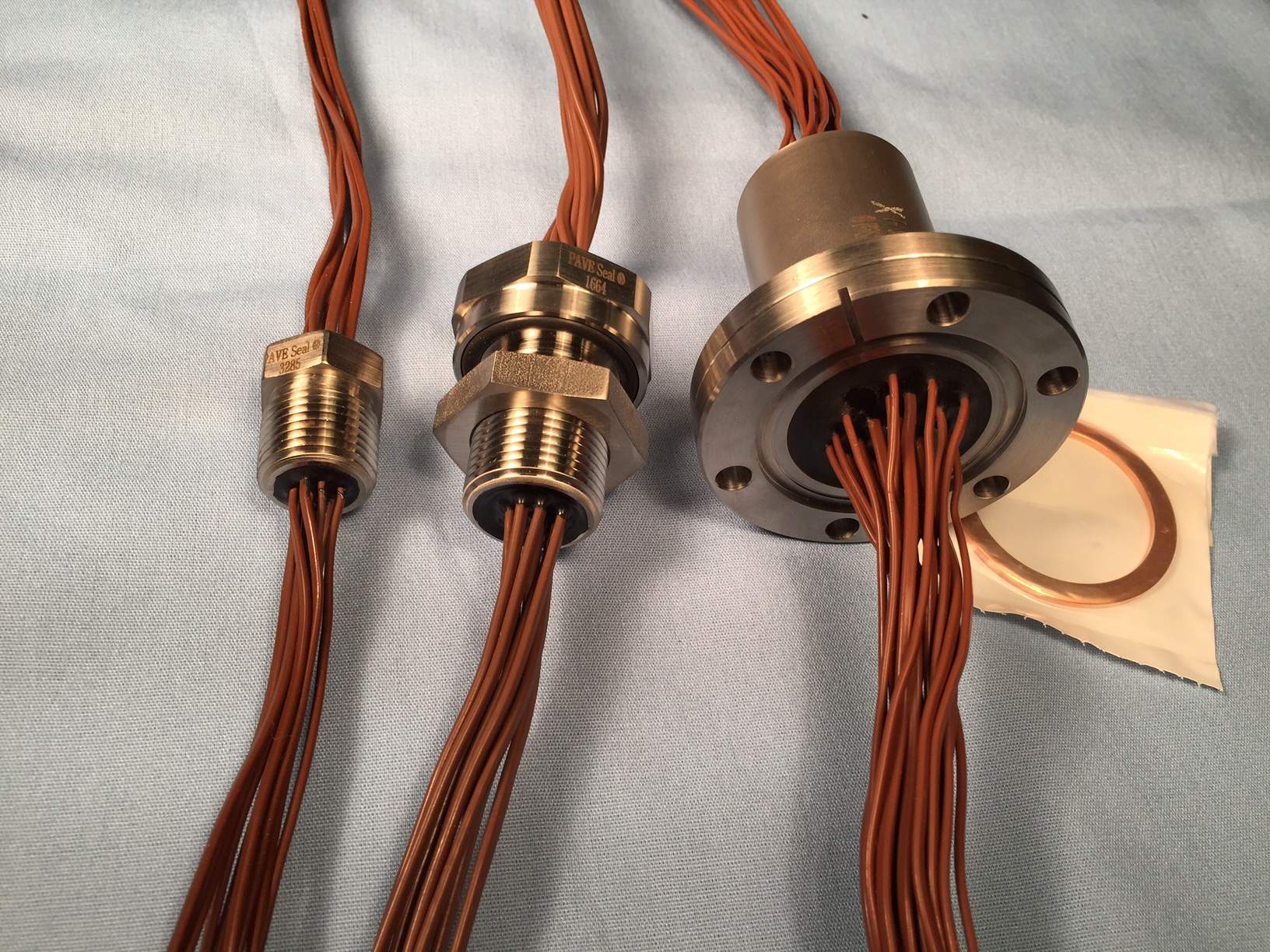

Vacuum electronic feed-throughs are made up of multiple key components that ensure their effective operation in maintaining vacuum integrity while allowing electronic connections. The key part of a feedthrough is the isolating material that separates the conductive conductor from the outside environment. This insulating material is commonly made from ceramics, such as alumina, or glass, which can tolerate high temperatures and maintain low outgassing rates. The selection of insulation material is critical, as it must also resist high voltages without failure.

The electrical conductors used in vacuum feedthroughs are often made from metals such as copper alloys or stainless steel, chosen for their excellent electrical conductivity and resistance to corrosion under vacuum conditions. These conductors are tailored based on the specific electrical parameters and environmental conditions of the use case. The combination of different conductor materials may also be required to enhance performance, especially in complex systems where different power requirements exist.

Sealing mechanisms are another crucial component for vacuum feedthroughs, ensuring airtight connections between the feedthrough and the vacuum chamber. Common sealing methods include the use of gaskets, glass sealing, or welding techniques, depending on the configuration and intended application. These connectors are engineered to prevent any air leakage, thereby allowing the system to sustain a stable vacuum condition while facilitating reliable power connections.

Uses and Benefits

Vacuum electrical feedthroughs are crucial components in diverse commercial and scientific uses. They are frequently used in vacuum systems, including semiconductor manufacturing, electron-based microscopes, and vacuum furnaces. These feedthroughs allow electrical connections while preserving the integrity of the vacuum environment, positioning them critical for processes that necessitate strict control over pollution and environmental conditions.

One of the main benefits of vacuum feedthroughs is their ability to offer reliable and stable electrical connections without compromising the vacuum seal. This is particularly important in high-tech environments where even small leaks can result in significant issues. By utilizing cutting-edge materials and design techniques, vacuum feedthroughs ensure that the electrical components function efficiently while enduring the harsh conditions often found in vacuum applications.

Additionally, vacuum electrical feedthroughs enhance safety and effectiveness. They minimize the risk of electrical failure and enable precise control of equipment, which is essential in applications like R&D. The ability to design custom feedthrough solutions tailored to specific needs also allows for greater flexibility, rendering them a versatile choice for various sectors, including aerospace, medical devices, and research studies.