Breakthroughs in Sealed Connectors: Technology that Shields

from web site

In a world where technology continues to evolve at an exponential rate, the need for trustworthy and durable electronic components has never been more critical. Among these components, hermetic sealed connectors have appeared as a vital solution for shielding vulnerable electronics from harsh environments. These connectors offer an unmatched level of protection against moisture, contaminants, and other impurities, securing that devices perform effectively in even the most rigorous conditions.

Understanding how hermetic sealed connectors work is important for engineers and designers who aim to develop robust systems. By employing a airtight seal, these connectors block the entry of outside elements that can jeopardize electronic performance. This groundbreaking approach to interaction not only extends the longevity of essential devices but also boosts their overall performance, making them essential in sectors such as aerospace, military, and medical applications. As we delve deeper into the mechanics behind connectors with hermetic sealing, we will examine their construction, functionality, and the benefits they provide to modern electronics.

Comprehending Hermetic Connectors

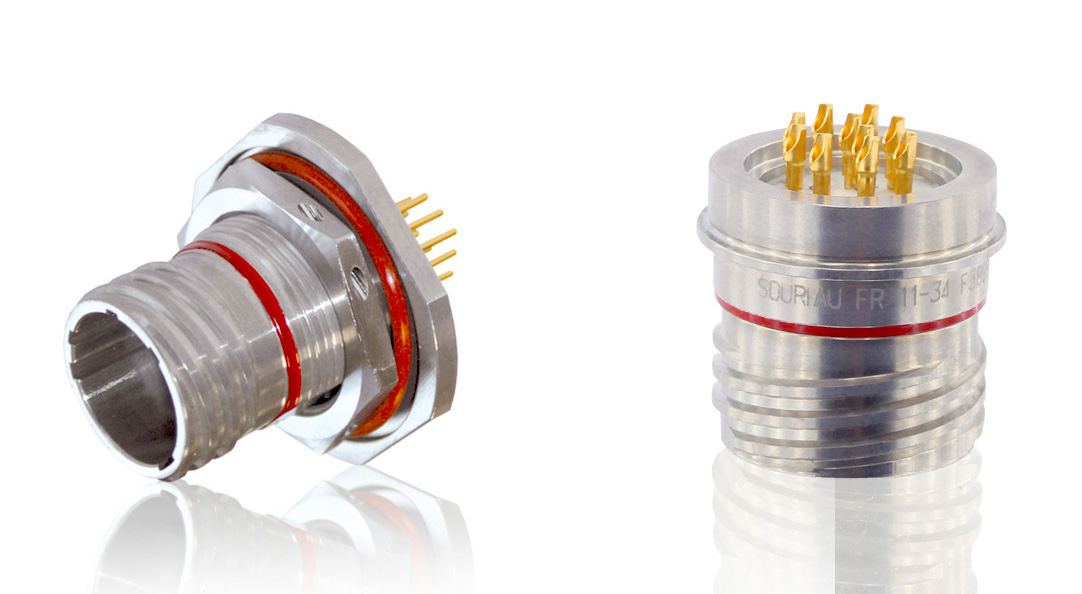

Hermetic sealed connectors are unique components designed to ensure a full shield against external factors such as humidity, particles, and corrosive gases. They maintain structural integrity by using a sealing method that stops the ingress of liquid or foreign material, making them essential in demanding applications where reliability is critical. The hermeticity of these connectors stems from materials and methodologies that let them to withstand harsh conditions, including elevated temperatures and pressure variations.

The key to the functionality of hermetic sealed connectors lies in their design. Typically, they consist of a metallic or glassy envelope that encases the connecting parts, effectively isolating them from the surrounding environment. This envelope is often soldered or sealed to create a durable, hermetic seal. Additional elements such as O-ring seals and sealed joints further enhance their ability to resist the entry of undesirable elements, ensuring that the internal wiring are safeguarded against deterioration.

Industries that rely on hermetic sealed connectors include the aerospace sector, defense, healthcare technology, and communication technology, among others. In these fields, the consistency of electrical connections is paramount, especially in harsh environments. By using hermetic sealed connectors, manufacturers can enhance the functionality and longevity of their devices, ultimately resulting in increased security and lowered maintenance costs.

Improvements in Tech

Recent breakthroughs in sealed connectors have changed the way electronic devices are protected from harsh environments. Innovations in material science have resulted in the development of advanced composite materials that boost sealing performance. These materials are engineered to tolerate severe temperatures, fluctuations in pressure, and harmful chemicals, ensuring the integrity of the links even in the most difficult conditions.

The integration of smart technology has impacted the development of hermetic sealed connectors. Modern designs include sensors that can monitor the condition of the connectors in real time. This allows for prompt identification of potential failures or degradation, significantly improving reliability and minimizing maintenance costs. These advanced connectors provide key data that can help enhance operations in critical applications such as aircraft, armed forces, and medical devices.

Lastly, innovations in production techniques, including 3D printing and precision machining, have contributed to more effective production of hermetic sealed connectors. These methods not only cut lead times but also enhance customization options, allowing manufacturers to develop tailored solutions for particular industry needs. As a result, businesses can enjoy enhanced performance and adaptability in their electronic systems, opening doors to innovation across multiple industries.

Applications and Advantages

Hermetic connectors are crucial in various fields where dependability and performance are paramount. In the aerospace industry, these links protect delicate electronic parts from humidity, dirt, and extreme temperatures, ensuring the functionality of aviation systems. Likewise, in the defense industry, hermetic sealing safeguards electrical devices from severe environments, contributing to mission success and operational safety.

In medical applications, hermetic sealed connectors play a essential role in devices that require a controlled environment. They help preserve the integrity of healthcare devices, ensuring that components remain free from contaminants. This is particularly critical in uses like implantable devices or medical diagnostics, where any exposure to foreign materials can lead to disastrous failures or health risks.

The benefits of hermetic sealed connectors extend further than their protective features. Their capability to maintain signal stability in difficult environments enhances overall performance of systems. This reliability leads to reduced costs of upkeep and service interruption, making them a cost-effective solution for sectors that cannot afford breakdowns. As technology improves, the need for such durable links continues to increase, driving advancements in design and materials that further enhance their capabilities.