Why We Love good PCB Assembly companies (And You Should, Too!)

from web site

Benefits of Utilizing a PCB Setting Up Solution for Automated Copper Printed Circuit Boards

A Short conversation on the whole PCB Assembly process. PCB assembly is just one of the most prominent method of developing and making electronic devices on the planet. China is currently called one of the most heartland of digital production. PCB production is one substantial market in China. As contrasted to other nations, Chinese manufacturers are quite interested in the layout as well as manufacturing of PCBs.

There are 3 preferred techniques of PCB setting up, namely through-hole, plug in-line as well as surface install. Through-hole is the procedure of applying adhesive between the PCB's text and also its external surfaces utilizing a soldering iron. On the various other hand, through-hole setting up process is suitable for smaller PCB dimensions. It involves application of glue along the PCB's sides and also along the base PCB's underside.

On the other hand, plug in-line PCB assembly involves soldering of elements on the PCB's bottom with the assistance of electric links. The elements' solder joints are covered by an unique product. On the other hand, surface area mount assembly makes use of aluminum or copper PCB installs to hold printed circuit card together with making use of clamps. On the whole, the overall process of PCB setting up includes 4 actions.

Designing and also preparing are the initial two steps in the entire process of PCB setting up. Designing is the step that supplies the basis of the idea as well as idea of your product. To put it simply, it is the phase where you make a sketch of the final product that will certainly be made. After conceptualizing, it is important to pick one of the most suitable and also unique published circuit card.

The next action is to compose a PCB plan. This plan is an illustration or format of the PCB. It contains full details regarding the placement and setup of the parts. It likewise describes which parts should be soldered and which should be soldered utilizing a solder paste stencil. As soon as a PCB design has actually been wrapped up, it is necessary to service the digital design. This involves the selection of the kind of PCB material to be made use of, its texture, and color, among others.

An additional crucial step is the application of the pattern. A pattern is an image or pattern that is utilized to hold the PCB together through the application of glue on the PCB surface area. As a whole, the stencils are supplied with sticky vinyl or some kind of adhesives to guarantee its efficiency.

Finally, a PCB assembly is completed when the PCB is placed to an appropriate fixture. Some components are constructed from brass plates, while others are built out of melamine. One of the most common and prominent components are those that are made of melamine. The setup usually takes much less time than that of plated through-holes.

Last but not least, after the assembly is completed, it is time to check it. To do this, one can use various kinds of testing approaches. One of the most generally utilized techniques are ultrasonic testing and ultrasonic discharge testing. Although they are non-intrusive in nature, they can be conscious some amount of mechanical pressure. Through-holes and wave soldering can likewise be examined; nevertheless, their performance during these sorts of screening are less trusted compared to that of the other two.

There are numerous advantages of using printed circuit card (PCBs) for electronic tools. One of its most noticeable attributes is its ability to suit the various sizes and shapes of digital components, https://kaizentechnology.co.uk which considerably enhances the general compatibility of electronic items made with it. It is additionally extensively readily available in a wide variety of ranges, permitting manufacturers to make it available to different individuals. Additionally, due to PCB's resistance to moisture, it is ideal for items that might be revealed to high heat such as electronic devices and medical tools.

PCB Setting up generates various advantages such as increased manufacturing, far better high quality, as well as reliability. Additionally, it enhances the speed of the product manufacturing process by reducing the number of manual mistakes. Additionally, it gets rid of costly errors and conserves the time required to settle the assembly procedure. With its reflow procedure, it also lowers the heat change that is created throughout the soldering process. Finally, it makes certain the compatibility of published circuit card with its digital elements throughout the final action of the production process.

One of the significant advantages of using PCB Assembly solutions is that they give a quick as well as efficient method of generating big amounts of PCB's that will not call for too much labor as well as cost. They provide top quality published circuit boards that are made of the very best feasible products and also can fulfill numerous needs of its customers. Additionally, the setting up services used by them to enable very easy and also quick shipment of the products to the consumers. This aids them in acquiring competitive benefit in the marketplace. Setting up of PCB's normally needs a high degree of accuracy as well as exact devices that are just obtainable via an expert PCB Assembly company. It is via these solutions that a producer will have the ability to decrease the overall expense of making the product.

Making Use Of the PCB Setting up service also allows a producer to reduce the expense of PCB's that have a low versatility such as plastic and polymer products. These kinds of PCB's usually have a tendency to stick if used with constant stress during the manufacturing process. Nevertheless, using automatic equipment such as automated equipments or tools helps in minimizing the total price of the product. Apart from this, it additionally ensures that the items get completed within the stipulated time period.

Advantages Of PCB Assembly

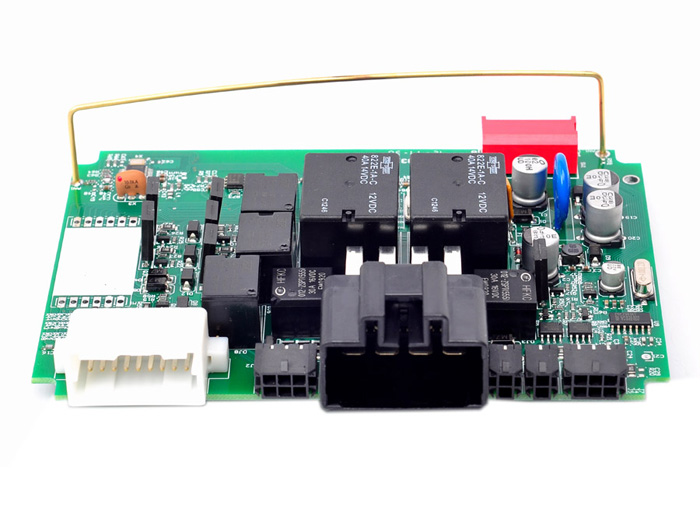

PCB Assembly is the approach by which various specific elements are connected with the purpose of developing a great working digital circuit (with outstanding performance). The published circuit card (PCBs) form the heart of various electronic tools that make use of in the present-day world. With the PCB Setting up process, a business has the capability to create a working design out of the different PCBs produced by one more company. A PCB Assembly specialist can solve the production related troubles as well as make sure that the time taken for each job is cut down.

The Printed Circuit Board setting up (PCB) technology helps to make a working version out of the digital parts utilized in digital gadgets. It has actually enabled the advancement of various products like digital devices, mobile phone, individual digital assistants (PDAs), laptop computers, global positioning system units (GENERAL PRACTITIONERS) and others. The very best thing about the PCB setting up is that it assists to develop a functioning model from square one which is distinct and different from others in the market. It additionally guarantees that there is uniformity in the design as well as result high quality.

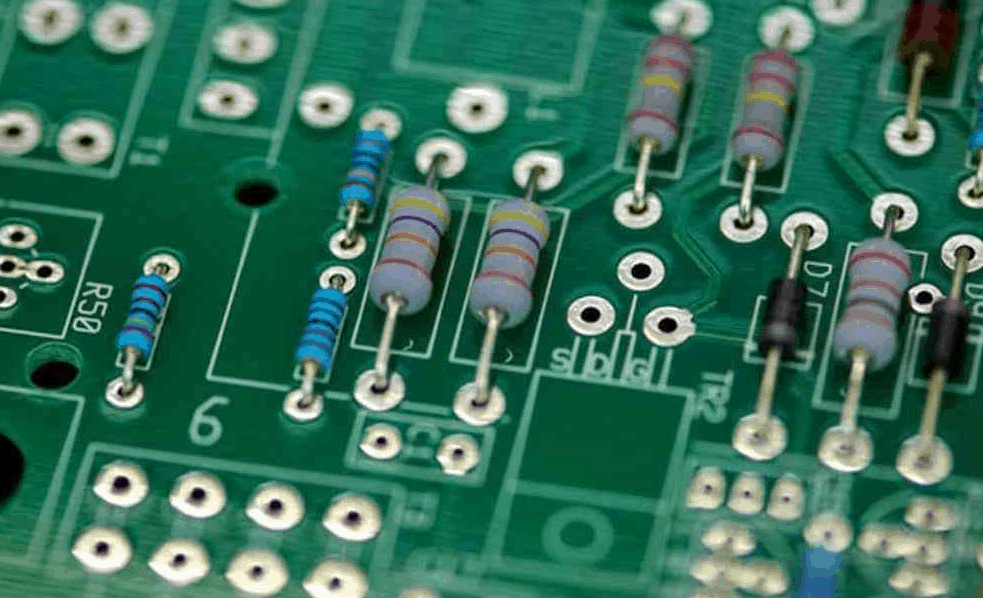

The major components in the PCB Setting up consist of conductors, published circuit boards, plating product, engraving material, heat-tunneled joints as well as solder masks. There are different strategies utilized for the PCB Setting up according to their usage. One of the most generally made use of technique is the through-hole modern technology that makes use copper holes. PCBS uses a thin layer of copper or silver for the objective of engraving the digital parts or soldered the parts onto the PCB surface area.

The other technique of PCB Setting up is the through-hole design, that makes use of numerous copper openings. An additional strategy called the notch-based PCB Assembly utilizes a specialized tool which is used to position the various components. This PCB design is commonly utilized in digital gadgets and also hardware as well as peripherals. The notch-based PCB Assembly entails a very small and precise soldering technique that is not feasible with various other techniques. The digital gadgets or hardware can be made portable therefore they need a PCB Setting up. Some of the prominent hardware, which are based on the PCB modern technology consist of as well as ATA cards, floppy disks, modems and also printers.

The materials made use of for the function of developing the PCB Setting up are numerous and one of the most popular among them are the copper wires, PVC, nylon fibers, as well as polyester. These PCB's are available in a big selection of ranges and also are widely made use of for both family and also industrial purposes. The method of using the PCBs is easy yet really budget-friendly. It has actually made the production of printed motherboard as well electrical tools and devices far more portable as well as cost-effective.

It is seen that the PCB modern technology has been greatly established in the recent years and also brand-new PCB's are produced on a regular basis. There are a multitude of advantages that bring out making use of PCBs. One major advantage is that it supplies high toughness to the printed motherboard and this implies that the electronic components of the product do not encounter any kind of kind of trouble with time. Another benefit is that the PCB's offer a cool and slim appearance to the electronic components, that makes them look far better. Last but not the least; the PCB's deal an extremely flexible and also recyclable style option which is not possible with the other PCB's. So, if you are searching for an alternative which can confirm to be advantageous for your item, then PCB is certainly the ideal solution for you.

If you are looking for an alternative that can make the manufacturing procedure of the digital components less complex, PCB will verify to be the very best alternative for you. It enables the producers to conveniently package the digital components in suitable boxes or containers and also this consequently assists in conserving a great deal of area. The PCB's likewise help in minimizing the expenses connected with the packaging process as the PCB's can be printed without adding any kind of extra price to the price of the product packaging. This also makes it possible for the suppliers to have a control on the expenses which would be sustained in the production procedure.

The majority of the parts require some type of finishing procedures to look good and also look even more appealing. Nevertheless, most of the parts do not need any kind of ending up process and this makes the manufacturing process of these elements really easy. Making use of PCB assembly in the manufacturing procedure has made a significant difference in the method a lot of the parts look and also this is due to the fact that they are readily available with an ideal surface. This suggests that you do not have to worry about the finishing procedure and also can utilize the completed PCB's for your next task which does not call for any kind of added ending up process. So, from the over it is evident that PCB setting up can verify to be beneficial for you.

Benefits of PCBS

PCB Assembly services by Diecutting Incorporated are committed to meeting the expanding demand of personalized circuit card. Bittele offers full Turn-key and full Turn-key PCB Setting up Solutions for worldwide manufacturing companies. Quality-driven PCB assembly technique guarantees that your end product is of top notch top quality.

PCB Assembly-through Hole as well as Via Opening placing and attaching of circuit boards are done through the use of die-cuts, blanking, trim, adhesive, metalized parts, UV covering and various other strategies. Several firms supply a variety of PCB Assemblies according to individual customer requirements. PCB Assembly services supply premium quality, affordable, as well as fast turn-around. Through-hole and also opening mounting processes enable manufacturers to develop durable, long-term, as well as cosmetically enticing PCB's.

With their huge documents dimension, printed circuit boards (PCBs) have enhanced in appeal with a range of consumers around the world. Printed circuit boards (PCBs) have actually gone beyond typical paper printed circuit boards as a result of their high dependability, premium efficiency, and expense performance. Several electronic gadgets are currently made with internet innovation. Most common electronic gadgets have several below parts. A maker can develop a PCB according to the spec of the client, consisting of file size, color, and parts.

Many leading digital gadget makers utilize pcb setting up capacities for long term production. To satisfy enhancing need, most top pcb assembly business have established advanced one-stop shop systems, which offer quick production capabilities and phenomenal value. One-stop shop systems supply innovative services for brief run PCB assembly capacities.

The new systems make it possible for manufacturers to produce countless PCBs using a single PCB maker. One-stop PCB assembly enables the assembly of total collections of PCBs https://en.search.wordpress.com/?src=organic&q=PCB Assembly and also elements. PCBS components include complete length, half-length, or single-sided published motherboard. These include solid state diodes, resistors, IC's, capacitors, interconnects, LEDs, as well as more.

Lots of leading pcb setting up centers use fully automated or semi-automated setting up procedure. They make use of fully automated configuration and tear-down and part mounting. They additionally make use of automated directing and also simulation devices. These devices help the center to handle a huge quantity of elements. They allow the quick manufacture and also accurate shipment of completed PCBs.

Most common attributes in production PCB's consist of data procurement, information show, as well as information conversion. Some components that are used in the manufacturing PCB's include circuit screening equipment, wiring, printed circuit card assembly maker, cable television joints, blowpipes, soldering station, soldering paste, change cored joints, ribbon wire, solder, continuity monitor, and more. One of the most generally made use of PCBS techniques are hot dip, stick, straight thermal roll dip, and also mechanical transfer. A major advantage of using digital produced PCB's is that they supply flexibility as well as scalability, in addition to integrity and also sturdiness.

Generally pcbs have a level surface and a hole format that can be personalized. The setting up of these components can be done from the inside out, though they are often through-hole innovation that allows holes to be drilled on the surface for elements that are to be placed inside a http://query.nytimes.com/search/sitesearch/?action=click&contentCollection®ion=TopBar&WT.nav=searchWidget&module=SearchSubmit&pgtype=Homepage#/PCB Assembly real estate. PCBS' that are through-hole have a smooth as well as flat surface and also are designed for use with heat shrinkable product packaging products. There are many distinct functions of the PCBS innovations including limited, effective fit, as well as uniform warmth shipment.

Through-hole pcb's have the capability to include fine information as well as have the capacity to work as multi-layered units with full or partial insulation, including through-holes. One of the most common reason they are called multi-layer part mounting systems is because you can quickly solder or glue a number of PCBS' with each other to form a reliable as well as inexpensive option. With regards to PCBS 'it is essential to consider if the product being utilized for the PCBS' will certainly reveal with the openings. If the product has the ability to show with the holes then it will certainly be called thermally damaged, which suggests that the PCBS' surface area has been jeopardized in some way.

There are a number of advantages to using PCBS' with circuit card assembly abilities. The very first advantage is that it enables the manufacturing of PCB's that have greater circuit board assembly capabilities as well as sturdiness. When it come to using PCBS' the advantages include: versatility and scalability, greater product yield, raised toughness and reliability, improved flexibility and also enhanced conductivity, and optimized assimilation and also cable television administration. One more benefit to using PCBS' is that they permit the creation of versatile or wafer PCB's. The wafer PCB's are less expensive and provide a better degree of flexibility than the flexible PCB's.

To get the most out of your PCB Setting up services and the capacity to ensure that your project is finished to your requirements requires that you guarantee that the business you select will certainly give you with the items that you require. Among the numerous ways that a business can do this is by using a PCB stencil. A stencil is a piece of paper or plastic that can be made use of to ensure that your parts will look the manner in which you desire them to help lead you during the process of PCB assembly. The process that is associated with making use of a stencil will aid to make sure that the design of the PCB will certainly get on one side only and the solder will get on the opposite side. Utilizing a pattern will aid to create a uniformed as well as specialist looking setting up without using PCB shrink cover which can cause a large amount of variation. By using a top quality solder paste stencil, you will certainly have an expert looking PCB that will certainly fulfill or surpass your expectations.

An additional benefit to utilizing PCBS is that it will conserve you cash. As opposed to needing to buy every one of the materials that you require for each as well as every step of the procedure you will just be purchasing one item rather than countless materials. On top of that, having one-stop PCB setting up services will aid to conserve you time. It can be really time taking in to locate the proper dimension, amount, and color of the products that you need for a project and to then have to run from one store to one more searching for just the right thing. If you use a trustworthy company, you will not have to worry about these concerns due to the fact that your supplier will be able to obtain the things that you require from one resource and also will deliver them directly to you.