Tips of TIG welding for aluminium alloy

from web site

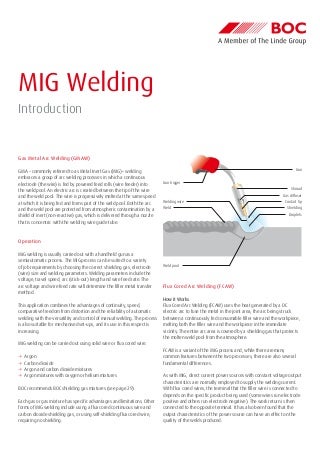

TIG welding (tungsten arc welding) of aluminum alloy is to make use of a large amount of heat created by the development of an arc between tungsten electrode and the work surface to melt the aluminum material, and after that fill up the welding wire to acquire a firm welding joint. The tungsten electrode and also weld area are secured by inert gas from the nozzle to stop response between the weld area and also the surrounding air.

TIG welding is suitable for welding light weight aluminum alloy sheet with a density of less than 3mm, its contortion is dramatically much less than gas welding and also hand arc welding. A/C TIG welding cathode can successfully clean the oxide film, without the use of flux to prevent welding deposit and slag rust. Its joint type is not restricted, will create excellent joints developing and also bright appearance. The erosion of the welding part by argon gas accelerated the air conditioning, boosted the structure and also efficiency of the joint, appropriate for all-position welding.

Air Conditioner TIG welding as well as AC pulsed TIG welding are the most frequently utilized approaches for welding light weight aluminum alloys, complied with by DC reverse TIG welding. AC welding of light weight aluminum alloy can attain the very best match in the present carrying ability, arc control and also arc cleansing. When straight existing connection (electrode connection), warmth is produced externally of the work surface as well as forming deep penetration. Although hardly ever utilized DC opposite link (electrode favorable) TIG welding approach to weld aluminum, but this approach is revealed effectively in continuous welding or fixing welding thin-walled warm exchanger, pipeline density below 2.4 mm, will certainly use a good melting deepness and arc easy to manage.

( 1) Tungsten electrode

Tungsten is the steel with the highest melting point.

Tungsten has a solid electron exhaust capacity at heat. When the tungsten electrode is added with the oxides of trace unusual earth elements such as thorium, cerium, zirconium, etc., the electron discharge is significantly minimized and also the present lugging ability is boosted. Throughout TIG welding of light weight aluminum alloy, tungsten electrode is primarily utilized to conduct existing, sparks arc as well as maintains arc burning generally. Commonly utilized tungsten electrode products include pure tungsten, thorium tungsten and cerium tungsten.

Welding procedure criterion

In order to acquire outstanding weld forming and top quality, according to the density of aluminum alloy plate, the welder ought to first select tungsten electrode diameter and form, welding cable size, shielding gas and circulation price, nozzle aperture, welding existing, arc voltage and also welding rate, and then reasonably readjust the welding procedure specifications according to the actual welding result. The primary technological criteria of manual TIG welding of light weight aluminum alloy include present, electrode, securing gas circulation price, tungsten electrode extension length, distance in between nozzle and also work surface, and so on. But also for automatic TIG welding, the arc voltage (arc length), welding speed as well as cable feeding speed are one of the most important aspects.

Parameters of TIG light weight aluminum www.weldermetals.com alloy welding:

1) Nozzle aperture and safety gas flow.

The nozzle aperture of aluminum alloy TIG is 5 ~ 22 mm, as well as the safety gas circulation is generally 5 ~ 15L/min.

2) Tungsten electrode expansion size as well as the distance in between nozzle as well as work surface.

Tungsten expansion size of butt weld is usually 5 ~ 6, fillet weld is generally 7 ~ 8. The distance from the nozzle to the work surface is typically about 10 appropriate.

3) Welding current.

This relies on welding voltage, density, joint type, welding area as well as welder skill.

Guidebook TIG welding utilizing AC power supply, welding density of much less than 6 aluminum alloy, the optimum welding current can be established according to the electrode size D according to the formula I= (60 ~ 65) D. The arc voltage is mostly determined by the arc length, which is normally approximately equivalent to the tungsten size.

4) Welding rate.

TIG welding of aluminum alloy must take on faster welding speed in order to minimize deformation. The general guidebook TIG welding rate is 8 ~ 12m/h; In automatic TIG welding, the welding speed is usually unmodified during the welding procedure after the criteria are established,.

5) The dimension of the aluminum alloy welding cable.

It is usually established by light weight aluminum plate density and welding current, and the diameter of the welding cord is proportional to them.