How Does a Brushless Electric Motor Work? - ThinGap high

from web site

Not known Factual Statements About How Does a Brushless Electric Motor Work? - ThinGap high

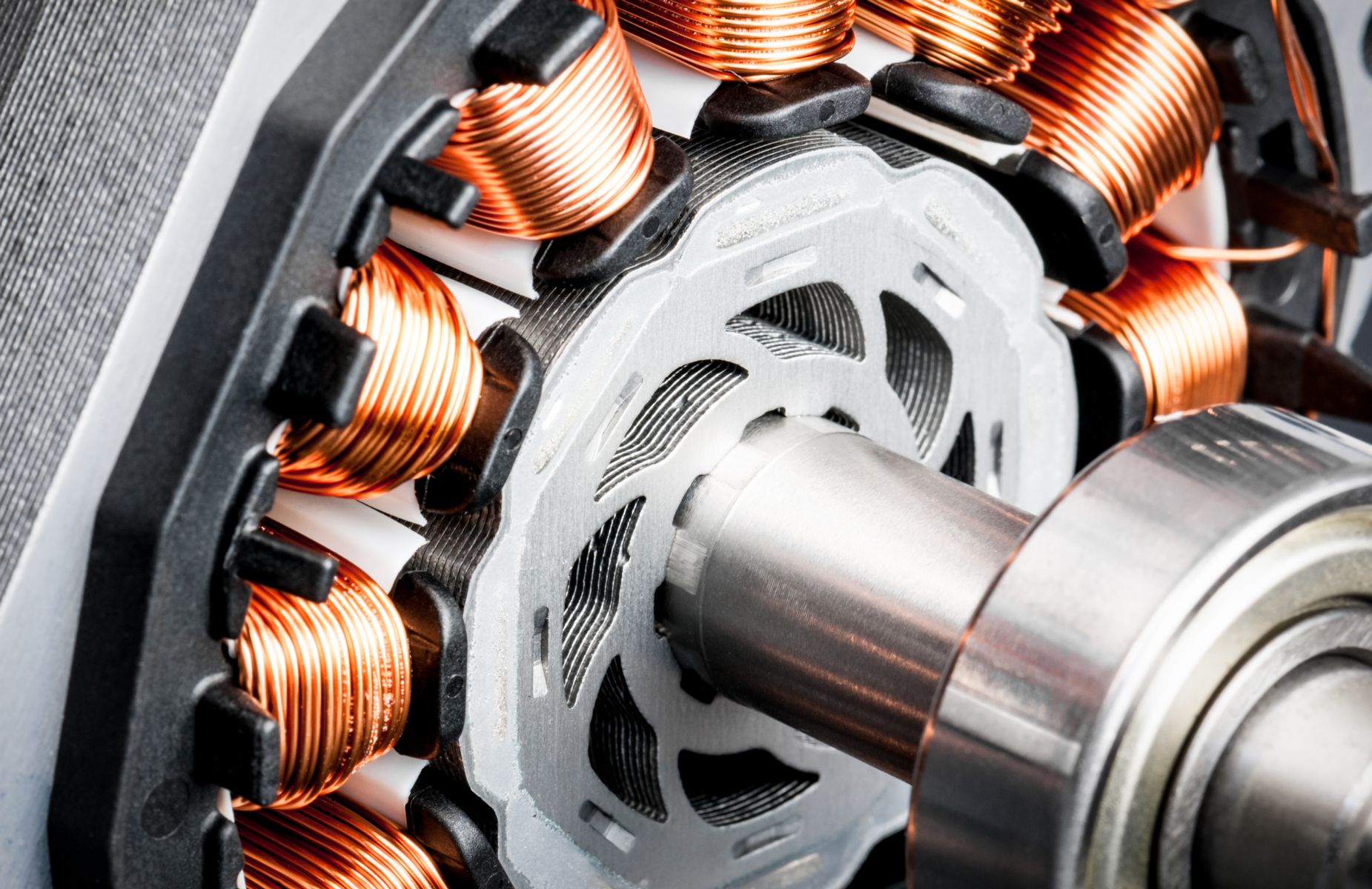

When transforming electrical energy into mechanical power, brushless motors are more effective than brushed motors mostly due to the lack of brushes, which decreases mechanical energy loss due to friction. The improved effectiveness is greatest in the no-load and low-load areas of the motor's performance curve. Environments and requirements in which makers use brushless-type DC motors include maintenance-free operation, high speeds, and operation where sparking is dangerous (i.

explosive environments) or might impact electronically sensitive devices. The construction of a brushless motor looks like a stepper motor, however the motors have important distinctions due to differences in implementation and operation. While stepper motors are frequently stopped with the rotor in a defined angular position, a brushless motor is generally meant to produce continuous rotation.

Both a stepper motor and a well-designed brushless motor can hold finite torque at zero RPM. Controller applications [modify] Due to the fact that the controller implements the traditional brushes' functionality it requires to know the rotor's orientation relative to the stator coils. This is automatic in a brushed motor due to the fixed geometry of the rotor shaft and brushes.

What are Brushless DC Motors - Renesas - An Overview

Others measure the back-EMF in the undriven coils to presume the rotor position, getting rid of the requirement for separate Hall result sensors. These are for that reason typically called sensorless controllers. Related Source Here that notice rotor position based on back-EMF have additional difficulties in initiating movement since no back-EMF is produced when the rotor is fixed.

This can trigger the motor to run backwards quickly, including even more complexity to the startup sequence. Other sensorless controllers can measuring winding saturation triggered by the position of the magnets to infer the rotor position. [] A common controller includes three polarity-reversible outputs controlled by a reasoning circuit.

More sophisticated controllers employ a microcontroller to handle velocity, control motor speed and fine-tune effectiveness. Two key efficiency parameters of brushless DC motors are the motor constants K T \ displaystyle K _ T (torque constant) and K e \ displaystyle K _ e (back-EMF constant, likewise understood as speed consistent K V = 1 K e \ displaystyle K _ V = 1 \ over K _ e ).