Some Known Details About Solvent-based separation and recycling of waste - PubMed

from web site

The Buzz on Tips for EPA TRI Reporting and EHS Data Management

D in chemistry, started an acetone recycling program in the chemistry building in June 2013. She composed a Sustainable CU Grant to acquire funding for the very first fractional distillation system on school, and matching financing was offered by the Chemistry Department and Facilities Managment. This acetone recycling achieves a general effectiveness of 76% and has actually conserved CU Boulder laboratories over $10,000 given that 2013, not to discuss the savings on disposal expenses for dangerous waste.

Methanol, ethanol, and other solvents can likewise be distilled in fractional distillation systems. In 2016 a second fractional distillation unit was bought for school with funds supplied by Facilities Management, and it is now in place in the Environmental Health and Security Building (EHS). Ethanol Reuse The Steady Isotope Laboratory at the Institute for Alpine and Artic Research (INSTAAR) uses ethanol cold traps throughout its analysis of ice core samples and at the end of the process, they are entrusted to a 85-90% diluted ethanol and water service.

Solvent Recycling - Eau Claire, WI - WRR Environmental for Dummies

Ethanol reuse has actually been in impact at CU Stone for a number of years with 120 gallons of ethanol/year being diverted from harmful waste and being re-used in Biochemistry cell culture, conserving the cell culture facility $1500/yr in prevented ethanol acquiring costs. The ethanol is transported between the two INSTAAR & Biochemistry Cell Culture laboratories by Environmental Health & Security.

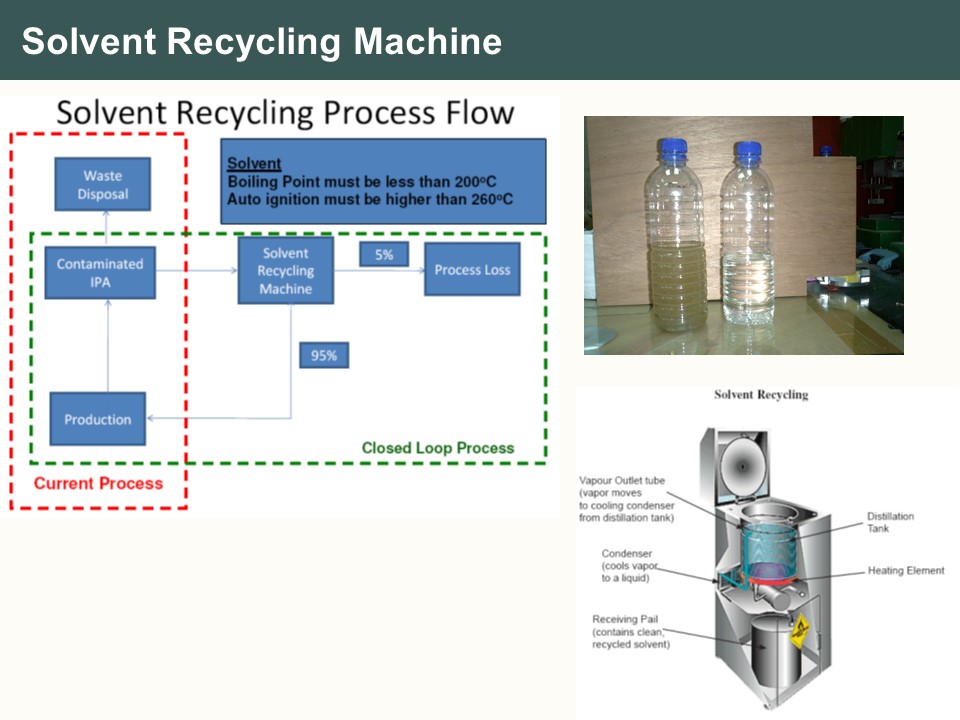

The high expense of solvents and the resulting waste cause unneeded costs that can be quickly conserved with an effective solvent recycling system. For a normal printer, one drum of virgin blanket wash used on journalism leads to about two drums of waste that can cost in excess of $300 to get rid of.

Some Known Questions About On-Site Solvent Reclamation A Guide for Hazardous Waste.

Solvent recycling and healing is created to help your facility accomplish 2 major objectives reducing liquid garbage disposal costs and recycling of your liquid solvent waste such as solvent waste, alcohol waste, blanket wash and liquid cleansing solvents supplying big economic benefits. With the rate of solvent continuing to increase, the Mara, Fix program permits you to eliminate pricey increases by acquiring your own recycled solvent back.

Based upon our experience with over 250 installed Solvent Saver Systems, the equipment typically pays for itself in less than 12-18 months!. You Can Try This Source minimizes your solvent purchases and waste, it likewise reduces your environmental impact. Solvent recycling and recovery lessens disposal costs, fresh chemical purchases and storage expenses.