Not known Facts About TC Bolts Womens Crop Hoodie - Hart & Huntington Tattoo Co.

from web site

What Does Tension Control Bolts, TC BOLTS & Fasteners CALL 800-822 Mean?

Tension control bolts, TC Bolts or Twist Off Bolts, have become one of the world's most commonly used method to tension high strength structural bolts, as they can be used in practically all steelwork connections. As a high strength tension control bolt supplier, AFT uses ASTM A325 and A490 TC bolts in bolt sizes varying from 5/8" as much as 1" and lengths from 1-1/2" up to 7".

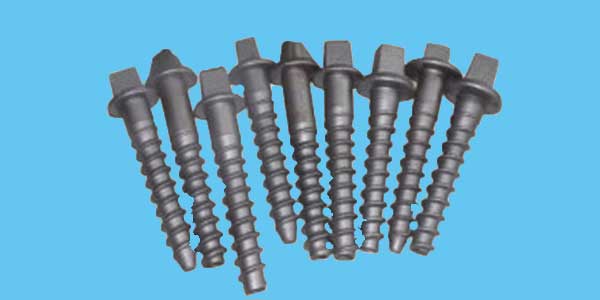

Please contract us today with any concerns on TC bolts or to ask for a quote on big amounts. We're here to help! TC bolts include a three-piece attachment system with 1) a round head bolt with a truncated, flat area at the top of the bolt, and a 24-sided tip which extends from the opposite end.

2) a heavy hex nut and, 3) a structural flat washer. Stress Control Bolt Resources:.

All About Tightening a Tension-Control Bolt without a Tension-Control

A tension control bolt is a pre-assembled bolt, nut, and washer used particularly in steel frame building and construction. Likewise called a TC bolt, they have a domed head instead of a hex head due to the fact that they are set up from a spline on their other end. This spline connects with an unique power wrench for setup.

Tension control bolts come perfectly pre-lubricated by the manufacturer. This Site are ready to be installed with a shear wrench. This wrench has an inner and an outer socket. The inner socket turns the spline clockwise and the external socket rotates the nut counterclockwise. When the correct stress has been accomplished, the spline breaks off.

There is just one lot number included in the tension control bolt assembly and they come precisely lubed. They are controlled by the AISC, American Institute of Steel Building, and RCSC, Research Study Council on Structural Links. The single most unique function of the stress control bolt is that it is set up with an exactly calibrated shear wrench that takes the guesswork out of attaining the appropriate preload (stress developed in a fastener when it is tightened).

6.6 Methods for Fully Tensioned Installation - American for Dummies

Numerous feel that stress control bolts are more affordable due to the fact that they require just one person for their installation and examination. For that reason, installation goes much faster and with less errors. Tension control bolts need to stick to requirements listed by the RCSC, as discussed prior to and any deterioration of the lubricant on the bolt will trigger it to fail assessment.