Just How ER70S-6 Welding Cord Better than any Other Welding Wire?

from web site

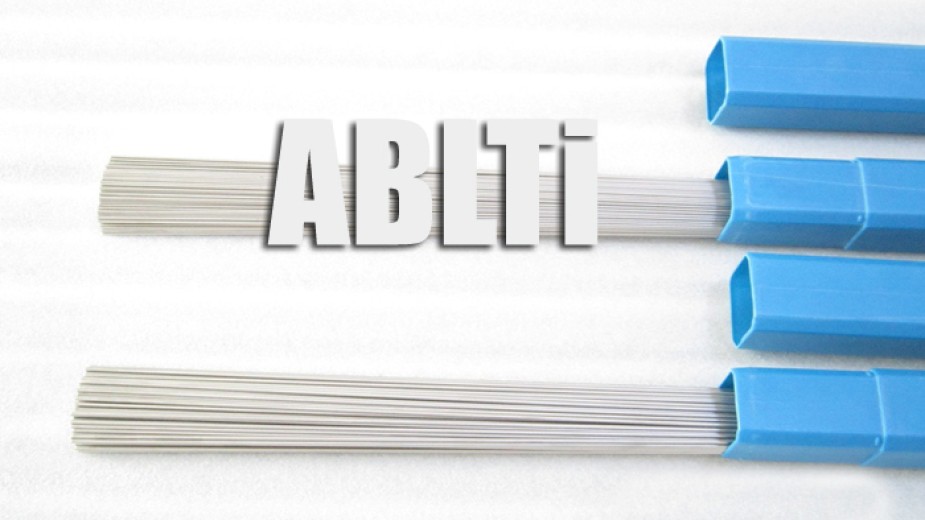

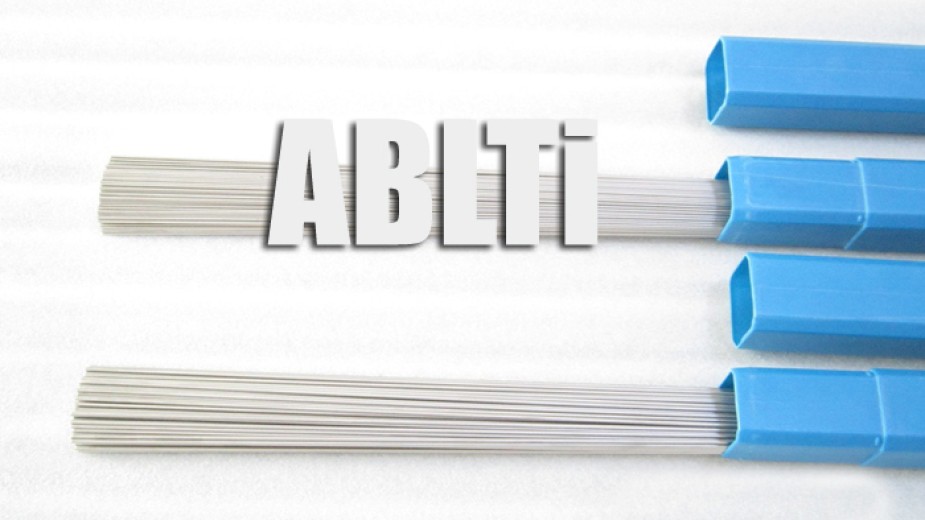

One needs to keep in mind that no 2 welding operations are having a comparable process. There are a great deal of business that count on the same type of filler steels to make certain the work is done. Solid wire is just one of one of the most typically used filler steels in the welding industry. It is one of the leading choices for those that work with applications that range from construction to manufacturing and upkeep. It is also deployed extensively in the repair service as well as welding of pipelines..

The convenience of application of strong wire is just one of the most vital factors for its popularity. It can weld various kinds of materials ranging from different density degrees. The innovation released in welding promotes the welding personnel of varying skillset to make proper welding with the help of a solid wire.

What makes the ER70S-6 welding cord the top selection for welding?.

There are certain things you need to remember when it comes to choosing a certain solid cable for a particular application. There are 308LSi MIG wires of solid cables and also they have various attributes. Each has its quality and also weld toughness. The levels of the post-welding clean-up likewise vary for every strong wire..

What are the necessary points you require to know about solid cord?

To recognize exactly how ER70S-6 welding cord is much better than any other welding wire. You require to recognize what strong wire suggests..

The ER70S-6 solid cable is just one of the top selections for moderate steel welding. This is very much discovered in applications like gentle fabrication and also automotive welding. This kind of solid cable is additionally made use of for robot welding and also pipe welding like path passes. It is additionally utilized in industry and various other essential applications. The strong cord provides uniformity and also level of smoothness together with terrific efficiency..

While utilizing ER70s-6 solid cable, one needs to make sure that there is an adequate supply of hundred percent CO2. This boosts the infiltration of joints together with the CARBON DIOXIDE blend. This must be made sure to reduce spatter. The ones who are utilizing this certain solid cord should know the reality that these solid wires have a tendency to produce silicone Island deposits. This develops a full surface area on the bonded steel. You will have to get rid of the silicone island deposits before paint or any other sort of surface conditioning. This would certainly subsequently boost the time of the whole welding procedure..

What are the various sorts of ES70S-6 solid wires?.

This solid cable has one of the highest concentrations of manganese and also silicon which is an excellent deoxidizer. There are different sorts of ER70S-3 soldered cords like ER70S-3 solid wires and ER80S-2 solid cables and also copper-free strong cables..

ER70S-3 solid cord.

ER70S- Welder Metals is made use of in the kind of applications where the surface should be extremely smooth and clean. This type of solid cable is just one of the top choices as well as automated and also auto welding applications..

AWSER80s - D2 strong cables.

When you wish to bond low-alloy steels and other sorts of metals, make use of AWSER80S-D2 strong wire. This type of strong cable provides high strength as well as tensile capability. This kind of solid wire causes outcomes that are good in high quality. They conveniently match the demands of high-strength applications. Solid wire welding is used for constructing construction. Manganese is one of the most effective deoxidizers and solid wires made using this particular element are just one of the most effective alternatives for dirty and also corroded metals. It likewise assists in enhancing the tensile stamina of the steel. The molybdenum aspect when released in solid wires in programs good temperature level managing ability..

Copper-free solid cords.

The copper-free strong wires are used for metals that have copper plating. This makes sure that the cable doesn't rust easily as well as it boosts electric conductivity between the two different steels made use of in the welding process.

As one might see, this type of solid wire matches various welding operations. It is one of the most favored and also one needs to ensure that the best kind of strong cord is made use of for the work. The mechanical and also other related residential properties should be taken into consideration. So in addition to the examination with the metal filler representative and supplier, this type of assistance would certainly aid you manipulate the full advantages of ER70S-6 wire.

The convenience of application of strong wire is just one of the most vital factors for its popularity. It can weld various kinds of materials ranging from different density degrees. The innovation released in welding promotes the welding personnel of varying skillset to make proper welding with the help of a solid wire.

What makes the ER70S-6 welding cord the top selection for welding?.

There are certain things you need to remember when it comes to choosing a certain solid cable for a particular application. There are 308LSi MIG wires of solid cables and also they have various attributes. Each has its quality and also weld toughness. The levels of the post-welding clean-up likewise vary for every strong wire..

What are the necessary points you require to know about solid cord?

To recognize exactly how ER70S-6 welding cord is much better than any other welding wire. You require to recognize what strong wire suggests..

The ER70S-6 solid cable is just one of the top selections for moderate steel welding. This is very much discovered in applications like gentle fabrication and also automotive welding. This kind of solid cable is additionally made use of for robot welding and also pipe welding like path passes. It is additionally utilized in industry and various other essential applications. The strong cord provides uniformity and also level of smoothness together with terrific efficiency..

While utilizing ER70s-6 solid cable, one needs to make sure that there is an adequate supply of hundred percent CO2. This boosts the infiltration of joints together with the CARBON DIOXIDE blend. This must be made sure to reduce spatter. The ones who are utilizing this certain solid cord should know the reality that these solid wires have a tendency to produce silicone Island deposits. This develops a full surface area on the bonded steel. You will have to get rid of the silicone island deposits before paint or any other sort of surface conditioning. This would certainly subsequently boost the time of the whole welding procedure..

What are the various sorts of ES70S-6 solid wires?.

This solid cable has one of the highest concentrations of manganese and also silicon which is an excellent deoxidizer. There are different sorts of ER70S-3 soldered cords like ER70S-3 solid wires and ER80S-2 solid cables and also copper-free strong cables..

ER70S-3 solid cord.

ER70S- Welder Metals is made use of in the kind of applications where the surface should be extremely smooth and clean. This type of solid cable is just one of the top choices as well as automated and also auto welding applications..

AWSER80s - D2 strong cables.

When you wish to bond low-alloy steels and other sorts of metals, make use of AWSER80S-D2 strong wire. This type of strong cable provides high strength as well as tensile capability. This kind of solid wire causes outcomes that are good in high quality. They conveniently match the demands of high-strength applications. Solid wire welding is used for constructing construction. Manganese is one of the most effective deoxidizers and solid wires made using this particular element are just one of the most effective alternatives for dirty and also corroded metals. It likewise assists in enhancing the tensile stamina of the steel. The molybdenum aspect when released in solid wires in programs good temperature level managing ability..

Copper-free solid cords.

The copper-free strong wires are used for metals that have copper plating. This makes sure that the cable doesn't rust easily as well as it boosts electric conductivity between the two different steels made use of in the welding process.

As one might see, this type of solid wire matches various welding operations. It is one of the most favored and also one needs to ensure that the best kind of strong cord is made use of for the work. The mechanical and also other related residential properties should be taken into consideration. So in addition to the examination with the metal filler representative and supplier, this type of assistance would certainly aid you manipulate the full advantages of ER70S-6 wire.