The Single Strategy To Use For Brushless Motors

from web site

The smart Trick of Developing micro DC-brushless motor driver and position That Nobody is Discussing

The high inertia of the rotor makes these motors suitable for constant responsibility applications that need really precise speed control. These motors likewise have actually incorporated speed control that can be set up for various speed profiles.

AboutPressCopyrightContact usCreatorsPromoteDevelopersTermsPersonal privacyPolicy & SecurityHow You, Tube worksCheck brand-new functions

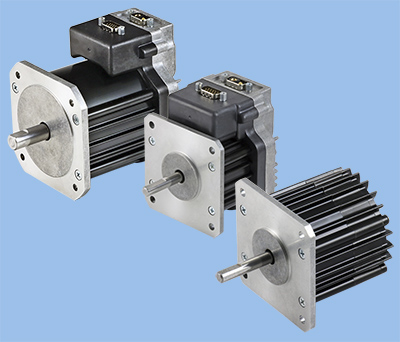

Extremely dynamic, overload capability and high power density, efficiencies of over 90% - these are the attributes of our BLDC motors. We are the leader of BLDC motors with integrated controls. Whether as sinusoidal commutated servo version or with Industrial Ethernet interfaces - our motors provide versatility to be combined with gearboxes, brakes and encoders - all from one source.

Brushless DC (BLDC) Motor Price List - ATO.com for Dummies

Ali, Express Mobile App Browse Anywhere, Anytime!

Brushless motors use many benefits over brushed motors, consisting of higher performance and reliability, less noise, restricted brush disintegration, and minimized electromagnetic interference (EMI). They likewise use a longer life and eliminate ionizing stimulates from the commutator. ultra small brushless motors that can be used to a brushless motor is very high, minimal just by heat capacity, which can harm the motor.

There are several types of brushless motors that serve specific applications. For circumstances, brushless motors with a a great deal of poles (approximately 64) are used in applications needing high torque and low speed. This setup gets rid of the friction, compliance, and reaction showed by standard speed reducers. Another type of brushless motors is limited-angle torquer (LAT) motors, which are constrained to produce torque through a rotation angle of less than 180.

The smart Trick of Introduction of Brushless Motors - Products Information That Nobody is Talking About

Inside-out motors, which have a cup-shaped rotor that rotates around an injury stator, are utilized to power spindles in disc drives, high-speed ventilation and air-conditioning systems, and other high-inertia devices.

The greatest distinction between brushed and brushless motors, unsurprisingly, is the brush. However what does that truly imply? The concept behind the internal operations of brushed and brushless motors are otherwise much the very same. When motor windings end up being energized, a short-term magnetic field is created to repel or bring in long-term magnets.

As the shaft rotates, the electric current is routed to different sets of windings, keeping electromotive repulsion or attraction, forcing the rotor to constantly turn. The History of Brushed and Brushless Motors Brushed DC motors have been utilized since 1856, and are still often used for electrical propulsion, cranes, paper machines and steel rolling mills.