The Best Strategy To Use For Brushless DC Motors (BLDC) - ISL Products International Ltd.

from web site

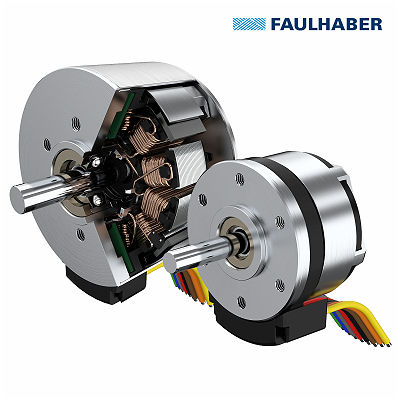

All About Small brushless motors - MinebeaMitsumi

They market the motor being extremely energy efficient and quieter than many fans. Industrial engineering [edit] The application of brushless DC motors within industrial engineering mainly concentrates on manufacturing engineering or industrial automation design. In manufacturing, brushless motors are primarily utilized for movement control, positioning or actuation systems. Brushless motors are ideally fit for manufacturing applications due to the fact that of their high power density, great speed-torque characteristics, high performance, broad speed varieties and low maintenance.

Movement control systems [modify] Brushless motors are commonly utilized as pump, fan and spindle drives in adjustable or variable speed applications as they are capable of developing high torque with good speed response. In addition, they can be easily automated for push-button control. Due to their building, they have great thermal attributes and high energy efficiency.

Brushless DC motors are widely used as servomotors for machine tool servo drives. Learn More Here are used for mechanical displacement, placing or precision motion control. DC stepper motors can likewise be used as servomotors; nevertheless, considering that they are run with open loop control, they usually exhibit torque pulsations. Brushless DC motors are more ideal as servomotors given that their exact movement is based upon a closed loop control system that supplies securely controlled and steady operation. [] Positioning and actuation systems [modify] Brushless motors are used in industrial positioning and actuation applications.

Motors that directly produce direct movement are called direct motors. The advantage of direct motors is that they can produce direct motion without the requirement of a transmission system, such as ballscrews, leadscrew, rack-and-pinion, web cam, equipments or belts, that would be required for rotary motors. Transmission systems are understood to present less responsiveness and minimized accuracy.

See This Report on DC Brushless Motors

To obtain linear movement, a motor controller thrills the coil windings in the actuator causing an interaction of the magnetic fields resulting in direct movement. Tubular direct motors are another form of direct motor design run in a comparable way. Aeromodelling [edit] A microprocessor-controlled BLDC motor powering a micro radio-controlled plane.