Three Dimensional Printing

from web site

Consider the three-legged pet. Possibly you have one, or have actually seen them in the park or in any one of the billions them. Lopsided yet resilient, they evoke a kind of fawning compassion from us people that's unparalleled by the typical quadruped pooch. "Individuals are drawn to specifically abled animals," says Rene Agredano, a cofounder of the pet-amputation support web site Tripawds.

"We simply intend to see to it that they are offered an equal opportunity at having a satisfied life." An increasing number of, that need to assist shows up as prosthetics, specifically in instances where the animal has actually lost greater than one arm or leg.

3d Printers For Educators & Professionals

A tortoise with wheels. 3D printing has propelled the sector forward. Printed prosthetics can be lightweight, affordable-ish, and also infinitely adjustable. find a Dallas IT consultantsDoctors craft beaks for birds. Senior high school students construct synthetic pet dog legs in their free time.

And some vets and people in the tripod community worry that the proliferation of conveniently craftable accessories can cause unintentional consequences for the pests that wear them. Dogs can shed an arm or leg for a range of reasons. Maybe they were birthed with an unusual arm or leg, or were hit by a vehicle, or established a cancerous growth that demanded an amputation.

3d Printing: What You Need To Know

Dogs adapt remarkably well to losing an arm or leg, claims Theresa Wendland, that concentrates on animal sports medication as well as recovery at the Colorado Veterinary Expert Group. Yet complications can develop as the animal makes up for what's missing. In older dogs as well as pets with arthritis or various other flexibility problems, placing added weight on the continuing to be limbs can be a large issue. "It really influences their spine movement," Wendland says.

"They need to draw themselves forward in methods that are extremely unnatural." Prosthetics, if squared away, can restore that array of movement. Yet as heart melting as it is to see a three-legged canine return to operating on four legs, it's challenging to develop a proper puppy secure leg. Wendland, who deals with the orthopedic and also prosthetic business OrthoPets to aid pets adapt to their brand-new limbs, claims that it's an engaged process that takes time as well as technical knowledge.

3d Printing And Rapid Prototyping

That indicates factoring in the pet's dimension, weight, elevation, stance, and stride (A set for a doberman won't fit on a dachshund). To do that, orthopedists have to study the pet's activities and attempt to mold an arm or leg that will sync up with the others. While strategies differ, a standard process is to make a cast, design the prosthetic based upon images as well as video, then develop it out with resilient thermoplastics and steel.

The process can take weeks. There's likewise the issue of the quantity of the limb that needs replacing. The excellent place to place a prosthetic, Wendland claims, is as low on the arm or leg as you can go. But if the whole limb is gone as well as there's no noticeable indicate connect a prosthetic, it gets much more difficult.

What Is 3d Printing? How Does A 3d Printer Work?

As well as now, a New Jersey based layout company called Dive Layout believes it's the service to full-limb substitute. It has partnered with a business called Bionic Animals that constructs exactly what its name suggests: accessibility tech for animals. Derrick Campana, that runs Bionic Pets, has long developed animal prosthetics by hand.

The arm or legs that Campana had actually been building made use of way too many resources as well as required excessive labor to be convenient. Plus, Tholl says, "With the waste that was involved, it just really did not make economic feeling. For us, that's when the wheels began transforming".

3d Printing Ally: 3d Printing Service For Rapid Prototyping

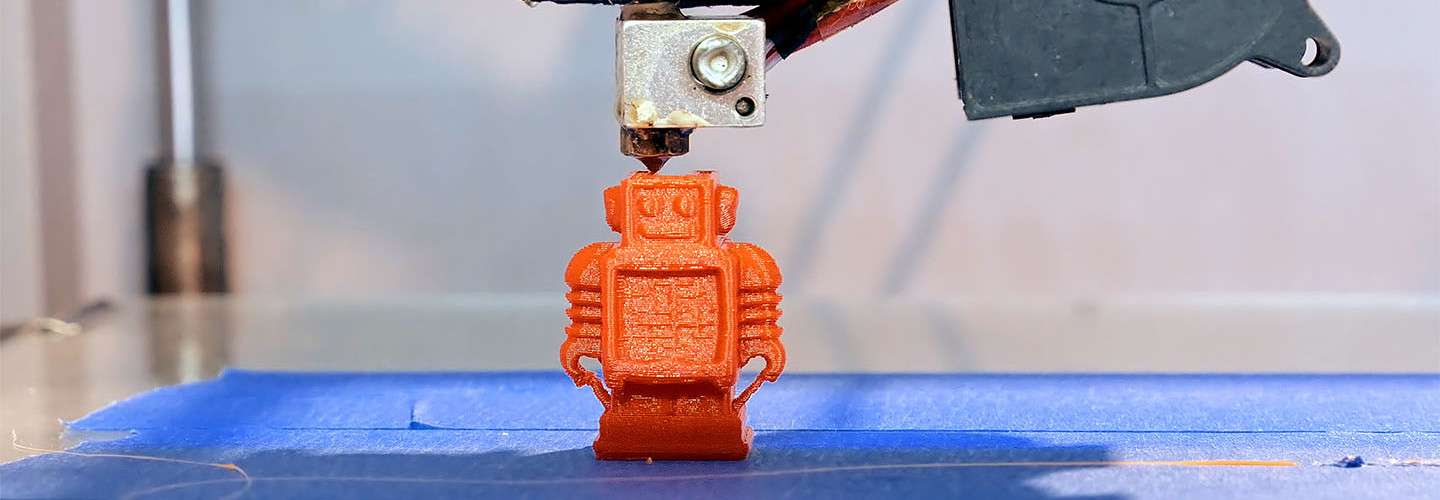

The beginnings of 3D printing in 'Fast Prototyping' were established on the concepts of commercial prototyping as a way of speeding up the earliest phases of item development with a quick and also simple means of generating models that enables numerous iterations of a product to get here a lot more promptly and effectively at an optimum service.

Prototyping is still possibly the biggest, despite the fact that in some cases neglected, application of 3D printing today. The developments and improvements of the process and also the materials, given that the introduction of 3D printing for prototyping, saw the procedures being occupied for applications further down the item advancement procedure chain. Tooling as well as spreading applications were established using the benefits of the different procedures.

Industrial Applications Of 3d Printing

In a similar way for final production operations, the renovations are continuing to assist in uptake. In terms of the commercial vertical markets that are benefitting considerably from industrial 3D printing throughout all of these broad spectrum applications, the complying with is a basic failure: The medical sector is considered as being one that was an early adopter of 3D printing, but also a sector with significant potential for growth, as a result of the personalization as well as customization abilities of the modern technologies and the capacity to enhance people's lives as the procedures improve as well as materials are developed that fulfill clinical grade requirements.

Along with making prototypes to sustain brand-new product development for the medical as well as dental sectors, the innovations are likewise made use of to make patterns for the downstream steel casting of dental crowns and also in the manufacture of tools over which plastic is being vacuum cleaner formed to make dental aligners. The modern technology is likewise benefited from straight to manufacture both supply items, such as hip and knee implants, as well as bespoke patient-specific products, such as hearing aids, orthotic soles for footwear, personal prosthetics as well as one-off implants for clients experiencing illness such as osteo arthritis, weakening of bones and cancer, together with mishap and also trauma sufferers.

3d Printing: What You Need To Know

Technology is additionally being developed for the 3D printing of skin, bone, cells, drugs as well as also human body organs. Nevertheless, these innovations remain mostly decades away from commercialisation. Like the medical market, the aerospace field was a very early adopter of 3D printing technologies in their earliest kinds for item growth as well as prototyping.