What Does Rebar Spreader - E-ZBAR Do?

from web site

Unknown Facts About Reinforcement Chairs And Spacers - Types Of Rebar Chairs

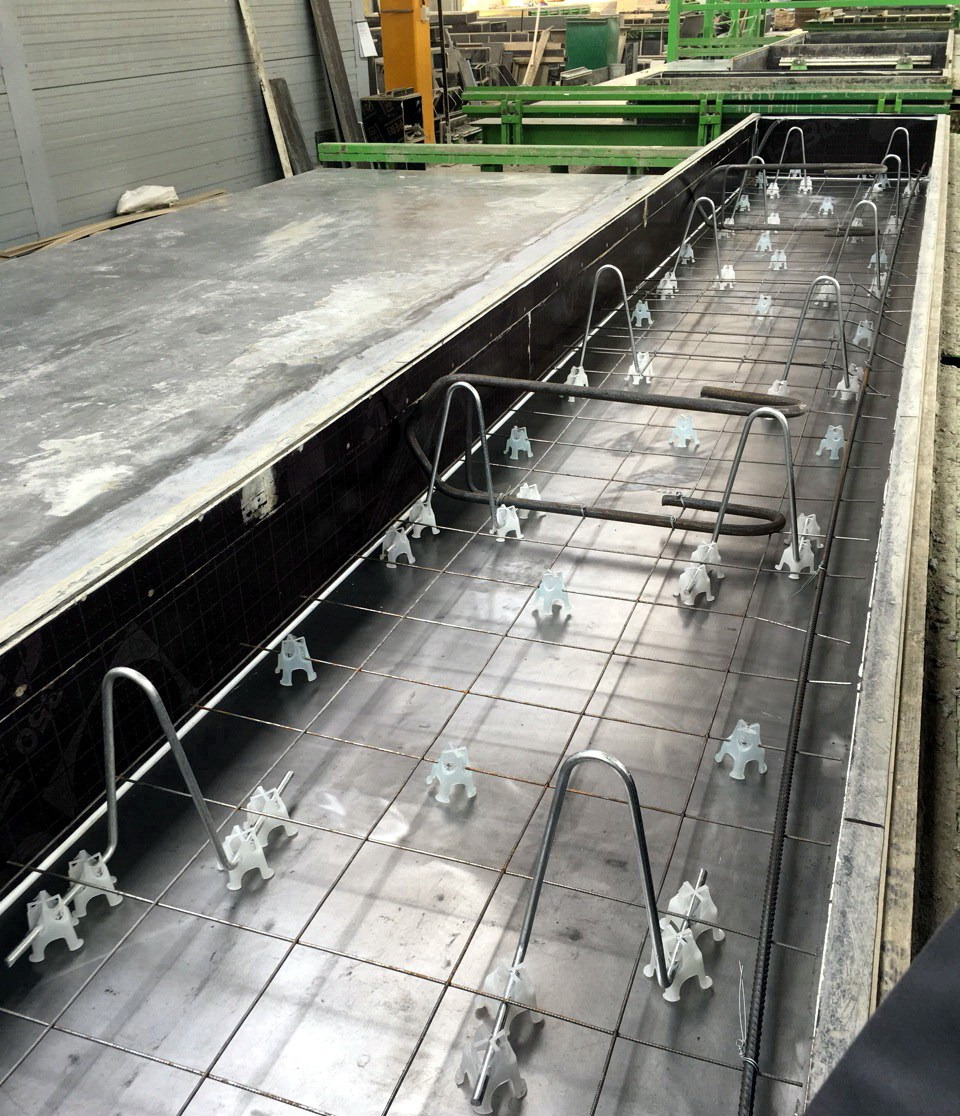

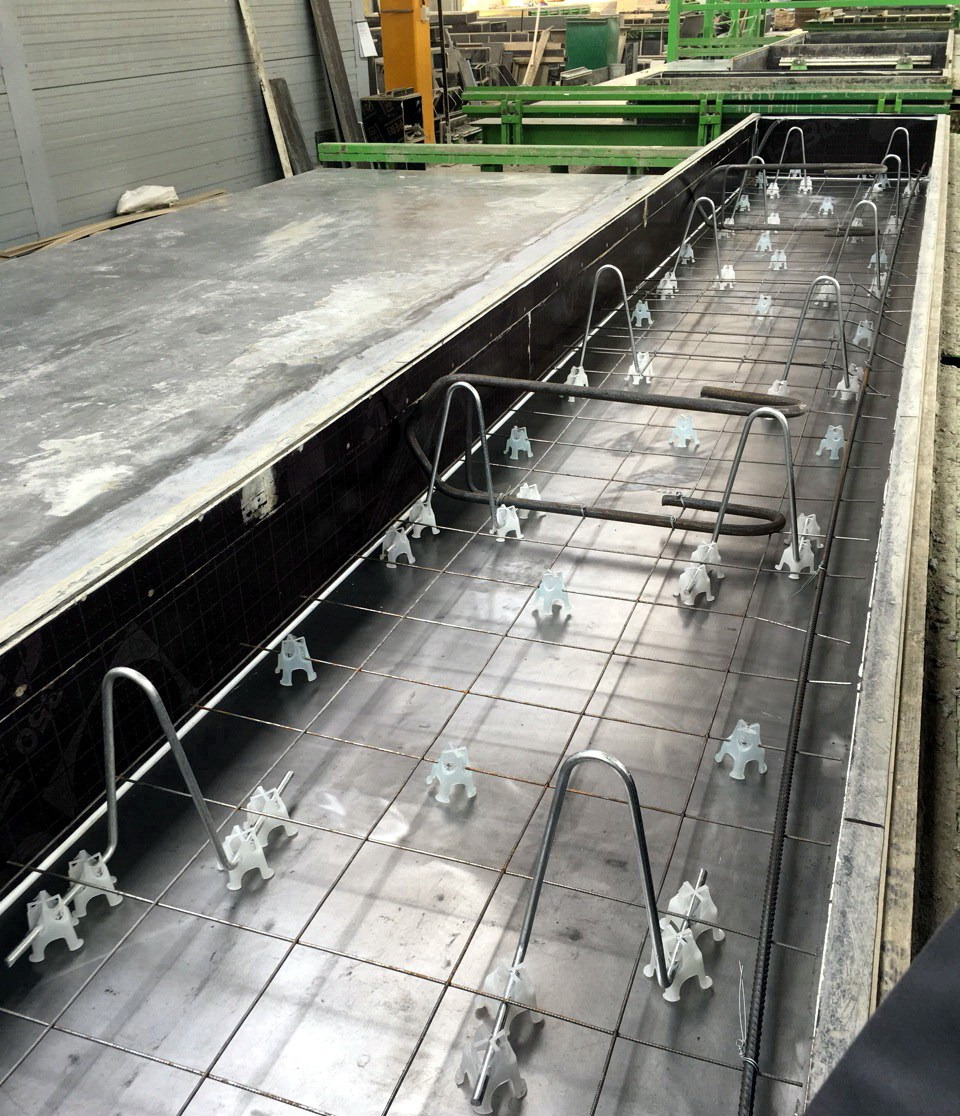

A concrete spacer with a plastic clip in use on the side of the formwork. Spacers on Lining elements for a TBM tunnel. A concrete spacer with a plastic clip in use Concrete spacers in a precast aspect Diaphragm wall block on rebar for a Diaphragm wall A rebar spacer is a device that secures the enhancing steel or "rebar" in strengthened concrete structures as the rebar is assembled in location prior to the last concrete pour.

The primary classifications of rebar spacers are: Linear Spacers (- area profiles, H-section profiles, or other 3 dimensional shapes), Point Spacers (wheel spacers, various tower or chair-like shapes) Rebar spacers can be divided in three raw materials classifications: Concrete spacers Plastic spacers Metal spacers The concrete spacers have the advantage of the same basic material which will enhance the watertightness and strength of the concrete.

Function [modify] The engineering research study of every reinforced concrete building, whether it is a structure, a bridge, a bearing wall or other structure, predicts the positioning of steel rebars at particular positions in the volume of concrete (predicted concrete cover of steel support bars). This cover usually differs in between 10 and 100 mm.

g. anti-earthquake security) along with to prevent the long-lasting rust of steel that would weaken the building. Rebar spacers secure the right position of steel, thus assisting in the practical application of the theoretical specs of concrete building. The cover of the steel of a particular building and construction component (for instance in a concrete slab or a beam) need to be generally uniform within the aspect.

The smart Trick of China Rebar Spacer, Made of PP or PVC, Different Sizes and That Nobody is Talking About

Plastic versus concrete spacers and bar supports [modify] Plastic spacers and bar supports [modify] Plastic spacers and bar assistances do not bond well with concrete, therefore they are NOT suitable materials. Much of this compatibility is explained through a single expression: Plastic has mechanical (holds the bar in position) however NO structural homes (constantly will stay a foreign element within the building).

Plastic has a coefficient of thermal expansion and contraction 10 to 15 times that of concrete, and when subjected to temperature level variations, the plastic continues to broaden and contract at that greater coefficient. At high temperatures, plastic can even melt. Official Info Here is a separation between the spacers and the poured concrete, developing a complimentary passage for corrosive representatives to reach the steel support from the outside of the concrete product.