Unknown Facts About 3D Printing @ Pendergrass - Research Guides - University of

from web site

The smart Trick of Give Your Creativity Dimension…Print in 3D - Frisco Public That Nobody is Talking About

Seattle Kid's is turning to Stratasys Digital Anatomy to prepare intricate pediatric surgical procedures. Artificial digital twins of an actual patient's anatomy, including the particular pathology in concern, is transformative. View how it assisted Nia. production: TE Connection scales parts production. P3 Photo, Polymerization technology and Origin One 3D printers let TE Connection turn to additive production to produce new lines of connectors at volumes not possible with injection molding.

Discover how. design: On the edge of reality. Kinetic Vision transformed beverage bundle design with multicolor, multimaterial Poly, Jet 3D printing. Discover how they save time, win service, and win over customers with Stratasys. manufacturing's big moment 3 brand-new 3D printing options to power your digital manufacturing. Introducing the F770, to print bigger for less.

The H350, for production-scale 3D printing with total control. Change 3d printers . Go to the virtual showroom and watch this year's biggest additive manufacturing statement.

Excitement About 3D Printing - Maker Commons

Provide the reality that ASTM F42/ISO TC 261 specifies seven various additive manufacturing processes, it is suitable to additional develop where making use of the term 3D printing is most suitable. One key distinction is the industrial vs consumer focus. While customers normally concentrate on the particular vs mass production of 3D-printed objects, businesses increasingly utilize additive production for the large-scale production of end-use items.

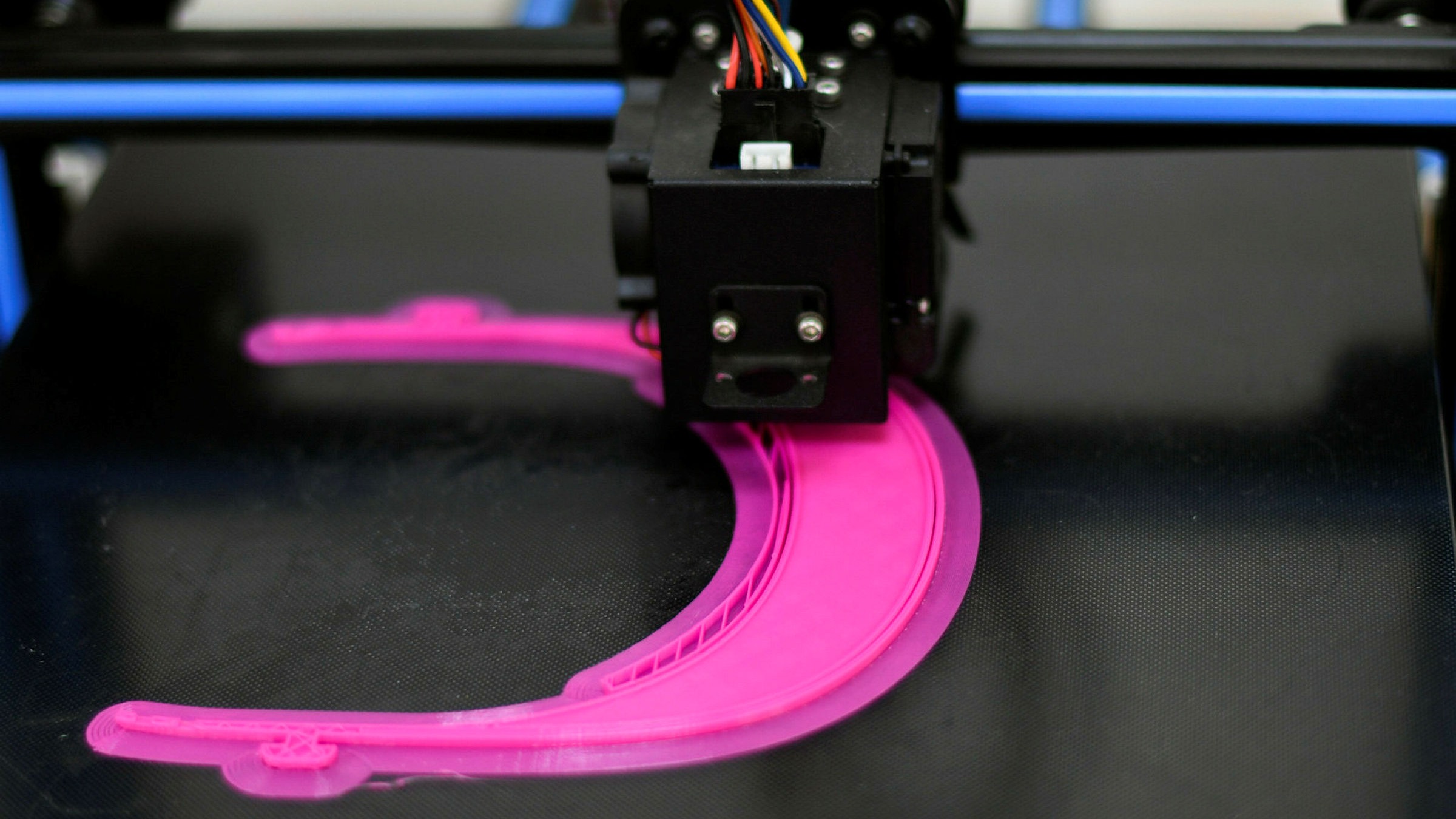

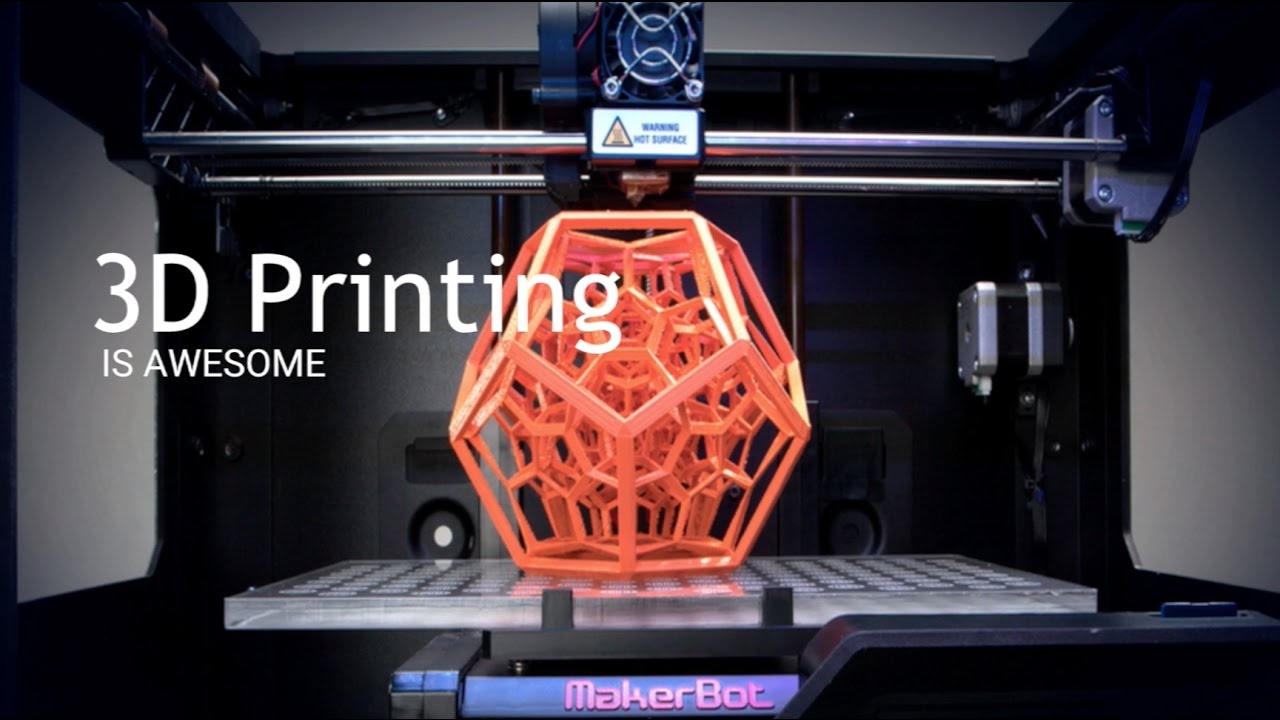

Producers more normally use AM to produce functional models, molds, mold inserts and end-use products, while the intent of customer 3D printing is more frequently utilized to print unique elaborate things like detailed vases and lampshades. The more sophisticated AM processes become, the more vital it is to identify them from inkjet-style, consumer-oriented production.

For instance, EBM and direct metal laser melting (DMLM) processes turn titanium and cobalt chrome metal powders into sophisticated components for rocket and jet engines. Progressively, manufacturers see additive production as a cost-saving option in certain scenarios where CNC machining, injection molding and financial investment casting were utilized in the past.

Unknown Facts About 3D Printing Services - Parts On Demand - Stratasys Direct

The seven AM processes are unique and typically quite different from one another. For instance, when the term 3D printing is used, few ordinary people make the connection to barrel photopolymerization, where an ultraviolet laser solidifies layers of liquid resin in a tank. Instead, most such people really believe of merged deposition modeling (FDM), simply among the 7 AM procedures, when they hear the term 3D printing.