The 30-Second Trick For 112,593 Hemp Fiber Stock Photos, Pictures & Royalty-Free

from web site

9 Easy Facts About Hemp Fibers - Rust Wiki - Fandom Described

Hemp grown specifically for this purpose is usually collected 70-90 days after seeding; early in the flowering stage and well prior to seed is produced. Double function hemp crops are collected later on and the fiber isn't normally used for fabrics; but instead for pulp, paper and non-woven items due to the higher lignin material.

Retting, Retting is a procedure involving using wetness and microorganisms to break down the chemical bonds (pectin) holding the hemp stem together, making it possible for much easier separation of the bast from the woody core (the hurd or shiv). Retting can be performed a number of methods: field retting, where the hemp is delegated decompose to a degree naturally through the action of dew, molds and bacteria.

All about Hemp Fiber - Knitting The Natural Way

Fibre Separation, In a procedure called "breaking", stalks are passed in between fluted rollers to squash and break the hurd into little pieces, separating a few of the fiber at the same time. As soon as a really involved and labor intensive procedure, separation of the bast from the hurd has been somewhat streamlined through a machine called a decorticator.

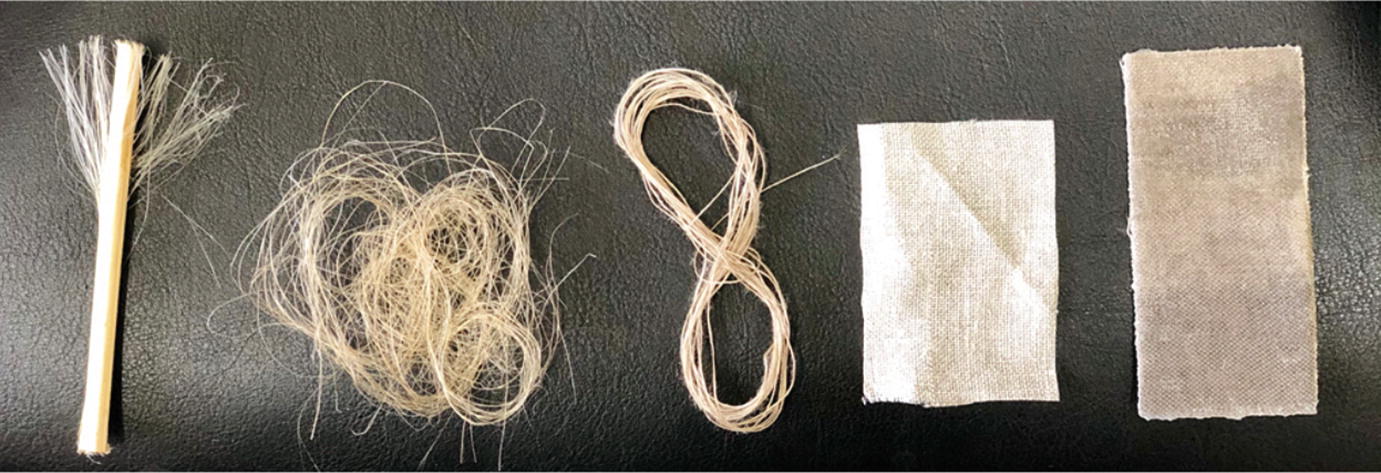

Decorticators make it possible for the leaves to be left on the stalks during the breaking, although this makes for a messier process requiring more arranging after completion. A further procedure called "scutching" beats and scrapes the fiber packages, separating more brief fiber and the staying hurd product from the long fiber. Answers Shown Here , The short fibers produced throughout the separation process are called tow and the long fibres are called line fiber.

6 Easy Facts About Industrial Hemp Seeds - Fiber and Grain Varieties - Rohrer Described

Via You, TubeWhen separated, the line fiber is cleaned and carded to size, cut and bailed; ready to be further processed and spun. The tow fiber is just compressed and bailed. Image: CC BY-SA 3. 0, LinkHemp tow is utilized for stuffing or coarse yarn spinning and line fibre for higher-end applications such as clothing materials, providing and floor coverings.

0, LinkHemp Fiber Yield, According to a USDA file, 3. 5% of the weight of "green" (unprocessed) industrial hemp can be converted dry line fiber and 1% of it to dry tow. This does not imply the rest is waste as almost every part of a commercial hemp plant has worth and function.