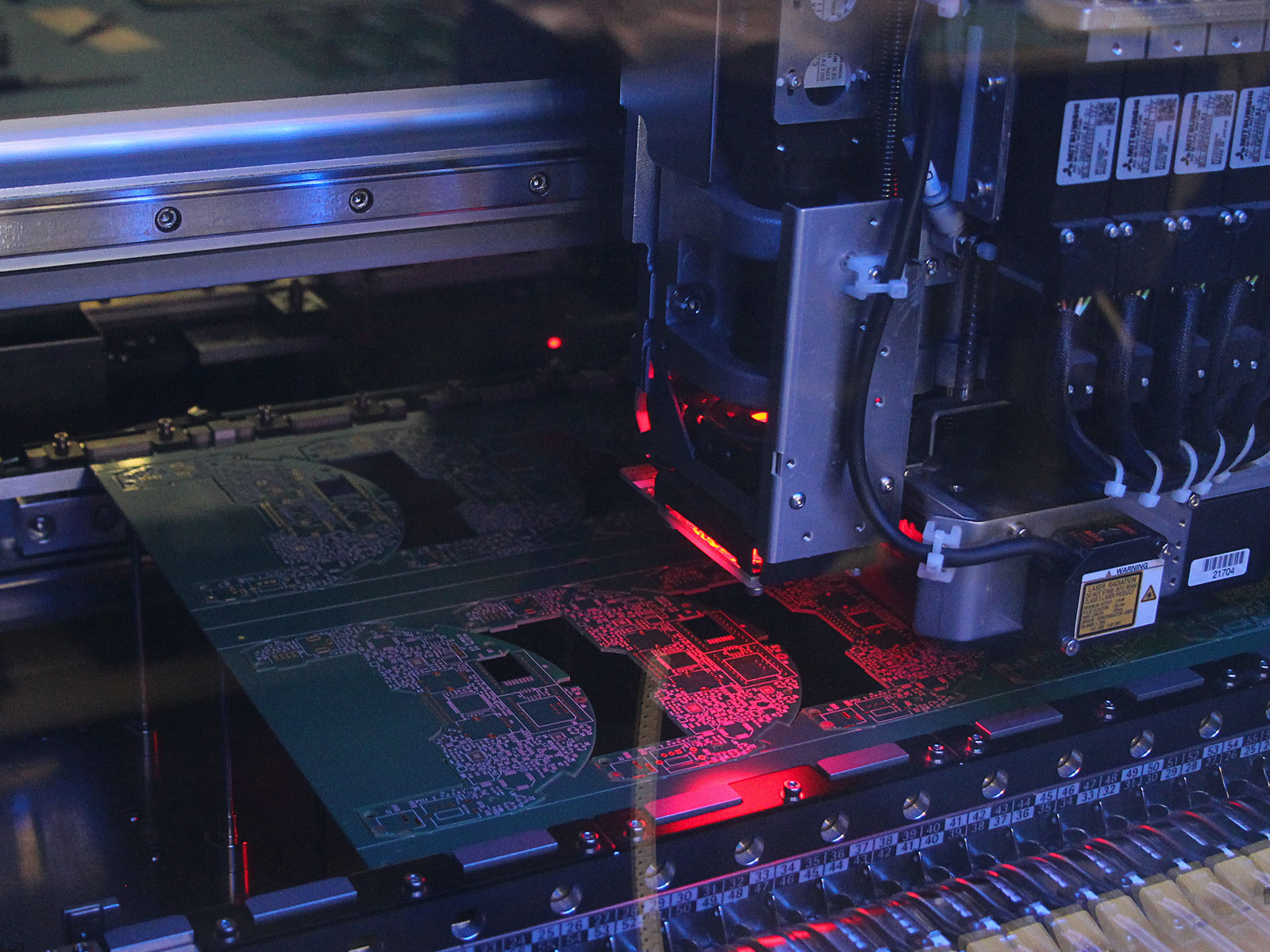

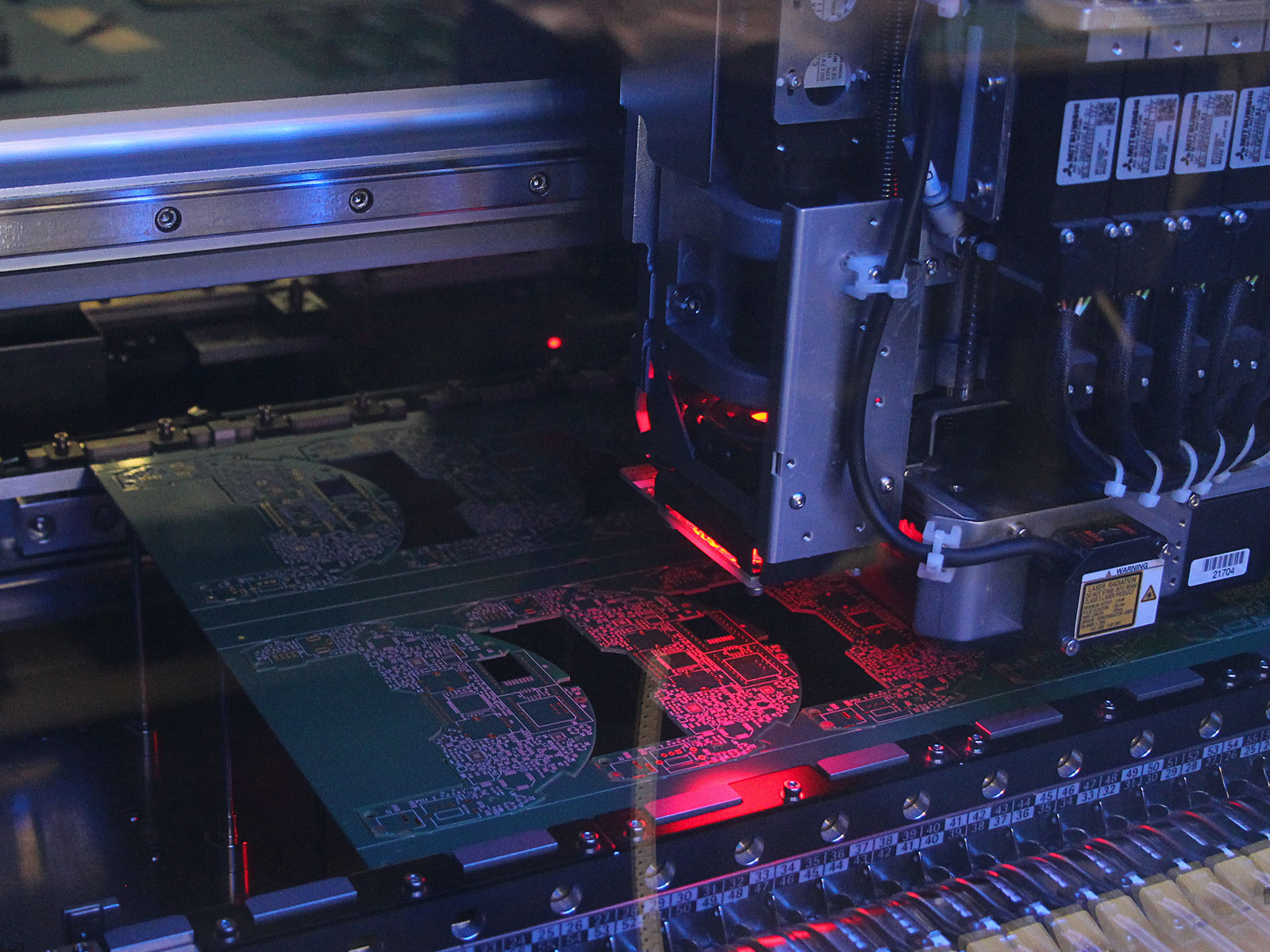

What is a Rapid PCB Prototype Service as well as Its Advantages

from web site

A PCB model is a crucial element of an item development process. The PCBs are manufactured on an in-house PCB assembly line, as well as the prototypes are utilized to fine-tune the design, examination capability, and also arrange the production process. These services can save you beneficial resources as well as time. You can have the models of your product within two days. There is no requirement to purchase expensive model tools or waste human or worldly resources.

PCB prototyping includes numerous various processes. The process involves producing a prototype of an electronic item, consisting of format, components, and also products. The ended up PCB can be tested by the end-user. This enables you to ensure that the item will work as developed. Numerous specifications should be defined, including the variety of layers, product, density, surface finish, solder mask color, as well as copper density. https://www.hitechcircuits.com/ of the most common products made use of for PCB prototyping consist of FR-4 glass epoxy and also polyimide. Both materials are strong and lightweight, so they are perfect for usage in PCB models.

PCB prototyping is a necessary part of the electronic devices producing procedure. It permits you to test a new design prior to hanging around and cash on the last production. It additionally enables you to decrease the general price of the task. It enables you to recognize problems early in the growth procedure, which permits you to boost your item prior to transferring to complete manufacturing. The PCB model service works best for start-ups that are seeking funding and also want to show a minimal viable item to possible capitalists. Nevertheless, you ought to bear in mind that PCB prototyping is not a simple process, and you should always work with an experienced professional before spending your money into a model.

The rate of the PCB model setting up solution is important to the success of a new digital device. By utilizing this solution, developers can examine the circuit style as well as include elements to see whether or not it works. Additionally, with a quick PCB prototyping solution, clients can view the whole design process, so they can make any type of needed adjustments prior to introducing the end product. It is necessary to see to it that your design will work before you actually start making.

The benefits of a PCB prototyping solution are countless. One of the most vital is rate. A PCB prototyping service should not just deliver the PCBs as quick as feasible, however it must additionally have precise details on your PCBs. A fast prototype service that can build a functioning computer board rapidly and also accurately will save you money and also time. A firm that can provide the end product rapidly is the best companion for your company.

The rapid PCBa model solution should have the capacities to meet your demands. A PCB prototyping solution must have the ability to take care of time-sensitive jobs as well as meet target dates. It must also have actually the required expertise of PCB manufacturing as well as design, so that it can provide the ideal level of client assistance. The procedure of PCB prototyping is a critical part of your item development, so it is crucial to find a firm that has the capacities to satisfy your requirements.

PCB prototyping includes numerous various processes. The process involves producing a prototype of an electronic item, consisting of format, components, and also products. The ended up PCB can be tested by the end-user. This enables you to ensure that the item will work as developed. Numerous specifications should be defined, including the variety of layers, product, density, surface finish, solder mask color, as well as copper density. https://www.hitechcircuits.com/ of the most common products made use of for PCB prototyping consist of FR-4 glass epoxy and also polyimide. Both materials are strong and lightweight, so they are perfect for usage in PCB models.

PCB prototyping is a necessary part of the electronic devices producing procedure. It permits you to test a new design prior to hanging around and cash on the last production. It additionally enables you to decrease the general price of the task. It enables you to recognize problems early in the growth procedure, which permits you to boost your item prior to transferring to complete manufacturing. The PCB model service works best for start-ups that are seeking funding and also want to show a minimal viable item to possible capitalists. Nevertheless, you ought to bear in mind that PCB prototyping is not a simple process, and you should always work with an experienced professional before spending your money into a model.

The rate of the PCB model setting up solution is important to the success of a new digital device. By utilizing this solution, developers can examine the circuit style as well as include elements to see whether or not it works. Additionally, with a quick PCB prototyping solution, clients can view the whole design process, so they can make any type of needed adjustments prior to introducing the end product. It is necessary to see to it that your design will work before you actually start making.

The benefits of a PCB prototyping solution are countless. One of the most vital is rate. A PCB prototyping service should not just deliver the PCBs as quick as feasible, however it must additionally have precise details on your PCBs. A fast prototype service that can build a functioning computer board rapidly and also accurately will save you money and also time. A firm that can provide the end product rapidly is the best companion for your company.

The rapid PCBa model solution should have the capacities to meet your demands. A PCB prototyping solution must have the ability to take care of time-sensitive jobs as well as meet target dates. It must also have actually the required expertise of PCB manufacturing as well as design, so that it can provide the ideal level of client assistance. The procedure of PCB prototyping is a critical part of your item development, so it is crucial to find a firm that has the capacities to satisfy your requirements.