Benefits of Using a Screw Assembly Robot

from web site

The screw assembly robot is just one of the most usual robot devices utilized in commercial settings. These devices are developed to take the repeated jobs out of the human hands and also minimize the threats of human error. These automated systems have numerous advantages including the decrease of labour costs as well as item issues. A screw assembly robot can be extremely flexible, allowing it to switch over jobs at will. A human employee can switch over to an additional job when the task ends up being as well laborious, or to finish a different task altogether.

Cobots are specifically well-suited for setting up line integration due to their small size. Due to the fact that of their close distance to human operators, they can supplement human workers in a high-volume production setting. Additionally, they use improved repeatability and high quality. A cobot can achieve torques of up to 500Nm. This guarantees consistency and quality in items. The screw setting up robotic can likewise be programmed to work in limited areas and also with varying degrees of precision.

Handbook as well as semi-automated screwdriver applications are typically made use of by electronic producers. Nonetheless, they are expensive and also inefficient for high-volume production. The automated robotic screw securing application improves effectiveness and also top quality. Best pneumatic screwdriver is an affordable option for high-volume production. The affordable investment in screw assembly robotics makes it possible for manufacturers to concentrate on higher-value tasks, such as production line. They can also be quickly integrated right into existing settings.

Screw assembly robotics are particularly beneficial in sectors that utilize little, precision-sensitive attachments. If these attachments are not made to exact criteria, the items may be inadequate and even unusable. A screw assembly robot with high precision can decrease the human labor workforce and raise the productivity and also earnings of the business. Its precision as well as repeatability make it optimal for tasks that need absolute accuracy. These robotics can carry out numerous jobs at high prices without the supervision of a human, as well as are qualified of attaining 0.1 mm or much less.

Making use of a screw assembly robot is a superb alternative for business that require to generate small-volume components. The robots have the ability to function efficiently as well as accurately, also in tight rooms, where labour is not constantly readily available. It also assists with high quality control. With precise and repeatable screw attachments, a robot worker can concentrate on more intricate operations, as well as can concentrate on enhancing production. Along with reducing labor costs, a screw assembly robot is a superb choice in high-volume manufacturing.

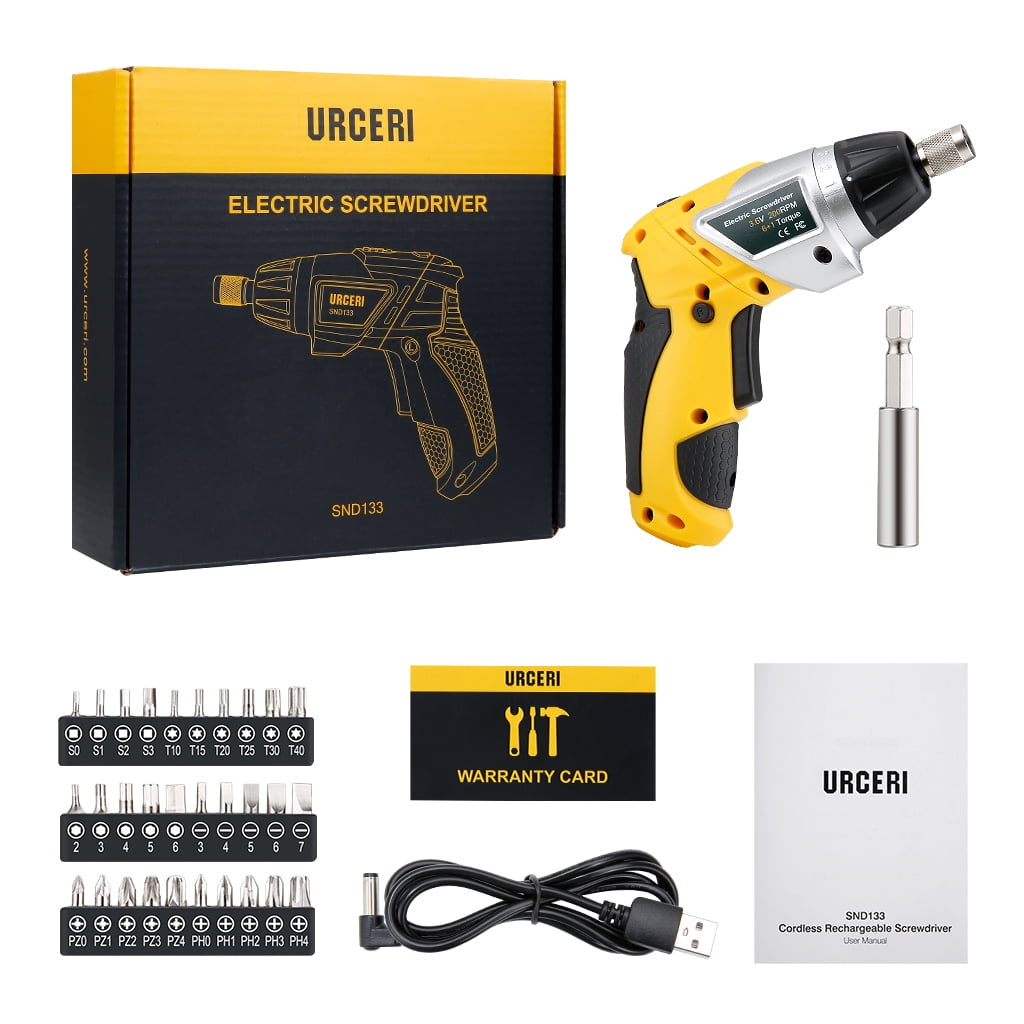

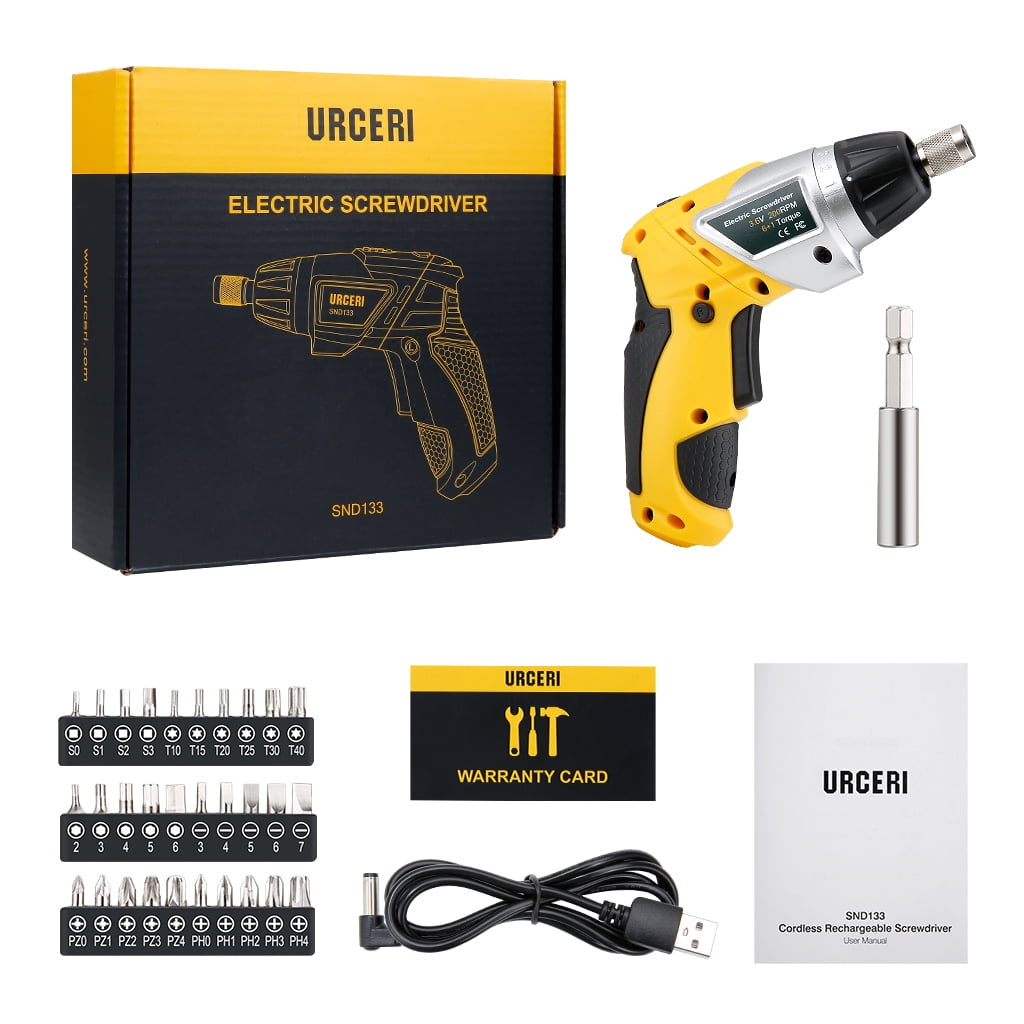

Screw setting up robotics are an exceptional remedy for lots of making procedures. They are simple to program and also work with several other kinds of screwdrivers and also can be incorporated right into your existing system. Furthermore, Cobots likewise have the benefit of being compatible with other kinds of robotic devices. electric screwdriver are easy to incorporate into your system and help enhance performance and also top quality. They are also inexpensive, as they work with a vast array of different robot devices as well as can be conveniently personalized.

Cobots are specifically well-suited for setting up line integration due to their small size. Due to the fact that of their close distance to human operators, they can supplement human workers in a high-volume production setting. Additionally, they use improved repeatability and high quality. A cobot can achieve torques of up to 500Nm. This guarantees consistency and quality in items. The screw setting up robotic can likewise be programmed to work in limited areas and also with varying degrees of precision.

Handbook as well as semi-automated screwdriver applications are typically made use of by electronic producers. Nonetheless, they are expensive and also inefficient for high-volume production. The automated robotic screw securing application improves effectiveness and also top quality. Best pneumatic screwdriver is an affordable option for high-volume production. The affordable investment in screw assembly robotics makes it possible for manufacturers to concentrate on higher-value tasks, such as production line. They can also be quickly integrated right into existing settings.

Screw assembly robotics are particularly beneficial in sectors that utilize little, precision-sensitive attachments. If these attachments are not made to exact criteria, the items may be inadequate and even unusable. A screw assembly robot with high precision can decrease the human labor workforce and raise the productivity and also earnings of the business. Its precision as well as repeatability make it optimal for tasks that need absolute accuracy. These robotics can carry out numerous jobs at high prices without the supervision of a human, as well as are qualified of attaining 0.1 mm or much less.

Making use of a screw assembly robot is a superb alternative for business that require to generate small-volume components. The robots have the ability to function efficiently as well as accurately, also in tight rooms, where labour is not constantly readily available. It also assists with high quality control. With precise and repeatable screw attachments, a robot worker can concentrate on more intricate operations, as well as can concentrate on enhancing production. Along with reducing labor costs, a screw assembly robot is a superb choice in high-volume manufacturing.

Screw setting up robotics are an exceptional remedy for lots of making procedures. They are simple to program and also work with several other kinds of screwdrivers and also can be incorporated right into your existing system. Furthermore, Cobots likewise have the benefit of being compatible with other kinds of robotic devices. electric screwdriver are easy to incorporate into your system and help enhance performance and also top quality. They are also inexpensive, as they work with a vast array of different robot devices as well as can be conveniently personalized.