The Facts About Plastic Foam Cutting Mechanics for Rapid Prototyping - CORE Uncovered

from web site

The 7-Minute Rule for SERVICES - 3D Custom Foam Inc.

Here is a list of 12 Development Boards you can use for your next prototype. The only function of a POC is to demonstrate the core functionality of your product idea, so things like aesthetics, custom-made PCBs and style are not a priority at this stage. The electronic devices may be enclosed in an off the rack plastic box with holes drilled in for buttons, or in a wood box.

Some manufacturers likewise offer a service to cut out holes and slots in the enclosure based upon your requirements. If you require something more custom made, processes like 3D printing and laser cutting can be utilized to develop a customized enclosure. Though it is recommended to keep things as simple as possible at the POC stage.

9 Simple Techniques For custom EVA foam Die Cut Eva Foam Packaging Insert

When the performance of your product is shown, you will require to relocate to a custom created PCB for your item. A customized PCB trim the unnecessary parts of a development board and helps reduce the internal space required in the real estate, it likewise helps you replace electronic components with comparable or better alternatives that help you simplify the supply chain and lower expenses further.

Item advancement business like ours have engineers and designers who help startups develop prototypes of their ideas. A "looks-like" model does not have any electronics or functionality, however it has the look of the last item. Official Info Here looks-lie" prototypes are completion result of the industrial style procedure where the outer look and feel of a product are developed.

Unknown Facts About Application of Subtractive Rapid Prototyping (SRP) For RSP

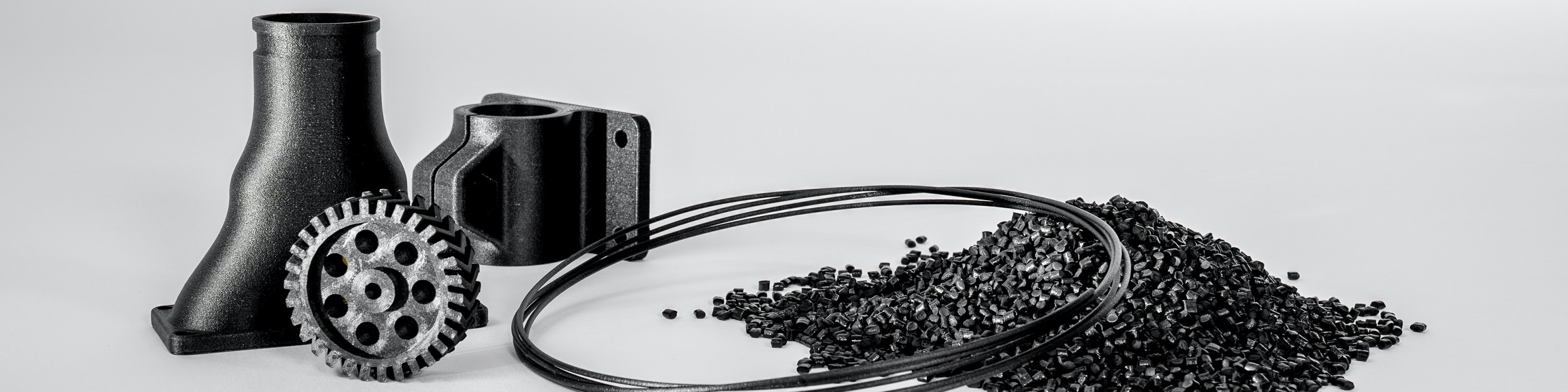

Industrial designers work on the visual appeals, CMF (color, product and surfaces) and the user experience of an item. Mockups made of foam or clay play a significant function in refining the type of a product and evaluating the ergonomics. Clay designs are used thoroughly in the automotive market whereas foam and 3D printed designs are more common for designers of consumer products.

The look models can also be utilized for generating buzz, beginning early marketing campaigns and demo functions. With the improvements in CGI/3D rendering software application, marketing projects can be started early without making a prototype. With our 3D rendering services for product marketing, it is now possible to evaluate your ideas, raise funding, and begin marketing projects early.