All About Rapid Prototype Machining in China

from web site

CNC Machining Services - Instant Quote Online - Fictiv Can Be Fun For Everyone

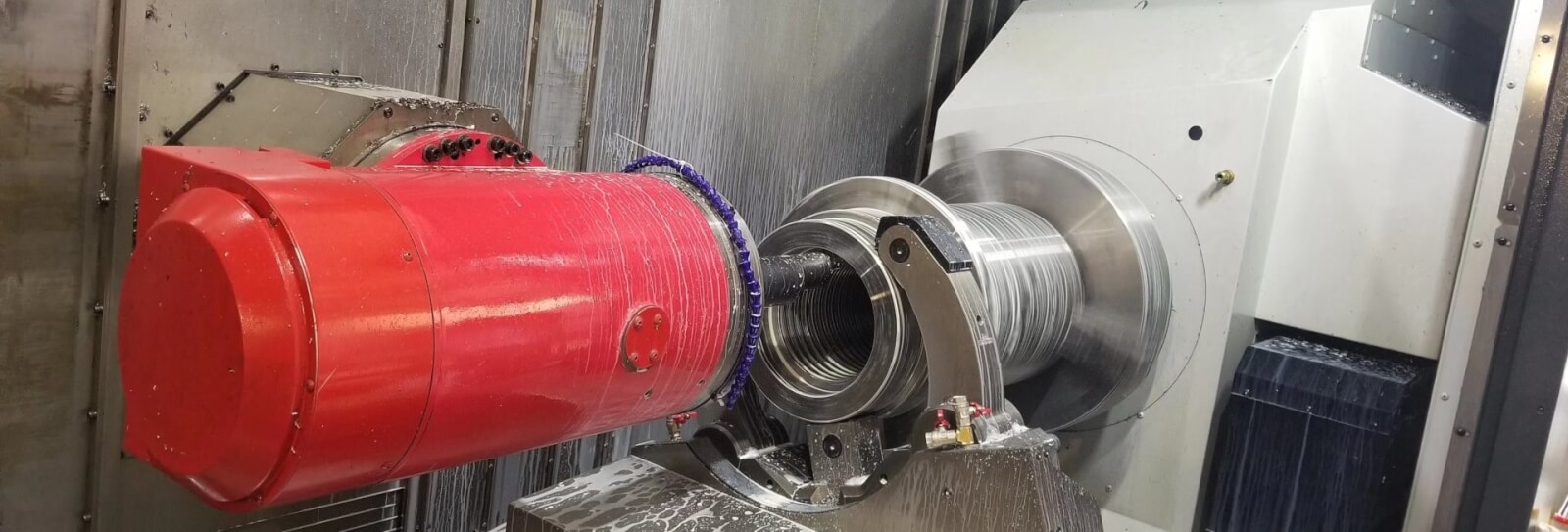

All type of services require high quality, precisely machined parts. Countless markets are using CNC rapid model machining for their material fabrication needs, including: High precision is required especially in aircraft travel parts, such as an aircraft turbine engine. Tolerances within the order of "0. 0001" are required to guarantee the compliance and safety of incredibly vital aerial parts for people and items dependability and security.

Poor item quality will cause equipment failure, bad video transmission quality, call disruption, and power failure of satellite broadcasting. CNC machining is one of the very best approaches to make sure the accurate manufacturing of telecommunication devices. More Details permits the style and production of complex parts. Communication equipment made by CNC needs to be maintained to date to adjust latest and future technologies.

CNC makers have the ability to process the necessary specific products and supply a completed final product, without any requirement for additional processing. When new items are developed, the fast prototyping ability permitted by CNC machining reduces time to market through low volume production. The most typical usage of CNC rapid prototyping in medical field is oral implants.

The smart Trick of Prototype Machining Services For Production Development That Nobody is Discussing

CNC machining puts just the ideal point, angle or bend on the instruments, along with the texture on the deal with that assists the experts tokeep their grip. A great deal of CNC milling makers have actually been used to produce the kind of precision parts that are utilized by the military corps in battlefield.

In this market there is no room for mistake; tolerances and maker tools should be kept an eye on for wear. Most of the equipments used in the vehicle market are being produced by CNC prototype machining. This technology is also utilized to make parts for bikes, extra parts for engines, and a lot more.

A number of vital parts of vehicle can be produced such as; engine cylinder, by utilizing CNC vehicle prototyping innovation. In it a big aluminum workpiece is converted into engine cylinder, in which the piston travels up and down at high speed producing heat. Electronic elements consist of real estate, test component, test socket, adapter, radiator and numerous metal and plastic parts are made with the aid of CNC model machining.