The Definitive Guide to Prototype Tips - Invention Ideas

from web site

The 10-Minute Rule for T2 Design & Prototype - Product design & invention prototypes.

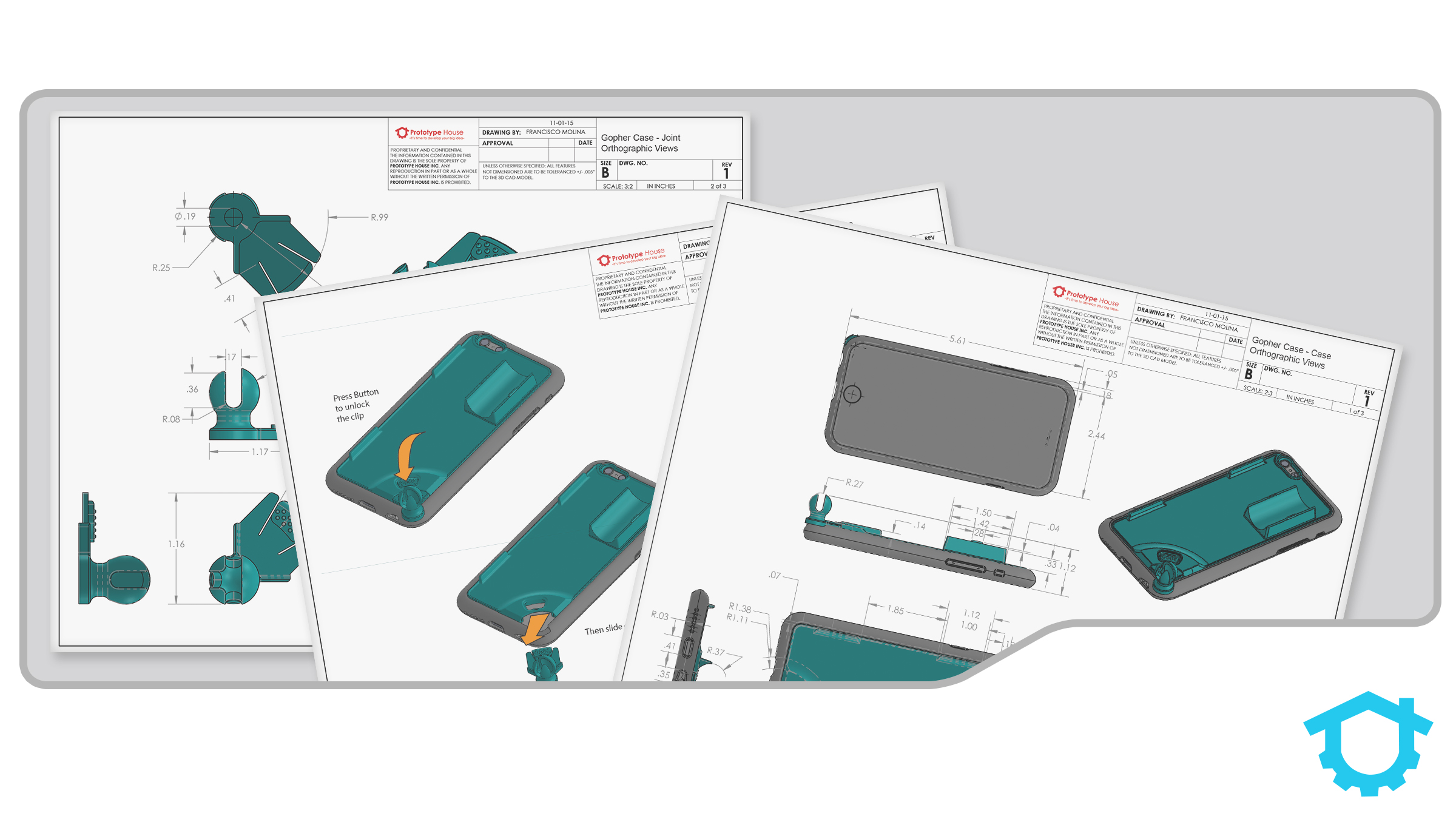

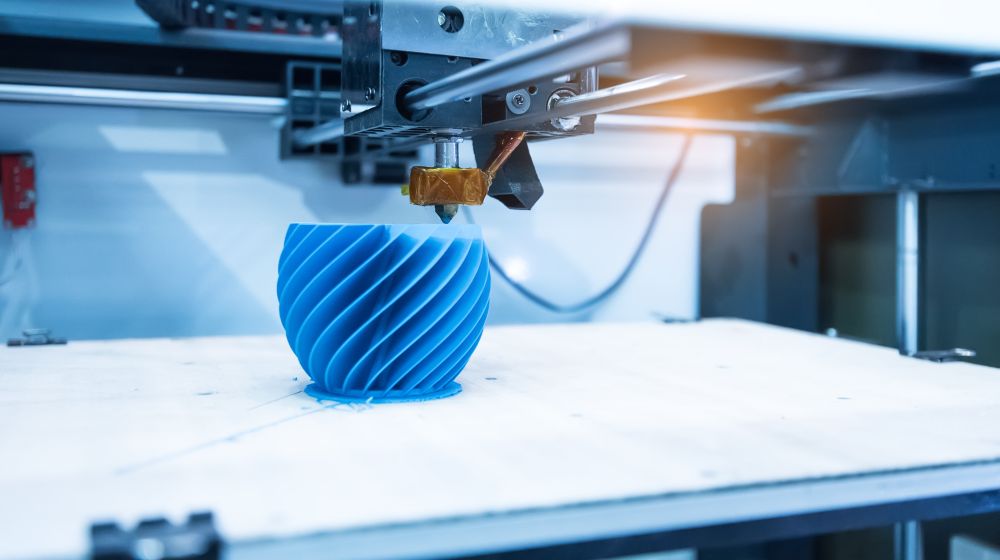

The 3D CAD file developed for strong modeling can be utilized to create a real part you can keep in your hands via fast prototyping. If you wish to imaginewhat an end product would appear like then you'll use photorealistic modeling to develop a photographic quality skin for your style.

Check out introduction to 3D printing here. Amodel is produced one layer at a time as a laser beam moves throughout a bath of liquid resin. The laser's motions are guided by a 3D CAD program. SLA enables a design to be made with high resolution because each layer can be very thin.

SLA parts are not used directly as working models because SLA resins are relatively breakable and weak. To make a working model a silicone mold is made from the SLA design and then plastic or metal copies (financial investment casting) are produced. Rather of using Find More Details On This Page powdered material - plastics, ceramics, waxes and specific metals to create a prototype part.

The Ultimate Guide To prototype Archives - Alotech, Inc.

Layer after layer is merged, one on top of the other. A model part produced with SLS can be made more powerful since products closer to actual production products can be used. If made from wax (or ceramic) an SLS part might be used straight for investment casting; if made from metal it might be used as a mold to create numerous plastic or wax parts.

The product, called "foil", might be plastic, paper or metal. Once the laser cuts a sheet another sheet is laid on leading and bonded to the previously cut sheet. Soligen's distinct and exclusive DSPC prototyping approach creates a ceramic mold for cast metal parts. Ceramic powder is "printed" and bonded one layer at a time.

The final prototype may utilize different products and be made with various devices and processes, but it looks and operates exactly like a production unit. It conforms to drawings that will be utilized to manufacture the item in mass amounts. A main reason to develop a final model is to insure that all of the parts fit together as planned prior to completing production tooling.