The Buzz on CNC Plastics Selection Guide - Fictiv

from web site

Comparing Plastic Injection Molding and CNC Machining Fundamentals Explained

So what products can be utilized for plastic CNC machining parts? Here are some common machining plastics: PEEK CNC machining is one facet of plastic manufacturing that uses PEEK material to form pasts. PEEK is a high-performance thermoplastic that has excellent machining residential or commercial properties and can stand up to chemical modifications better than the majority of other plastics.

Nylon is frequently used for CNC plastic machining due to the fact that it can endure wear and tear and does not react improperly to oil and fuel. Delrin is the shorthand name for acetal resins that are semi-crystalline thermoplastic polymers. When it pertains to plastic CNC machining parts, Delrin is a popular choice due to the fact that it can produce stiff parts, has low friction, and has high dimensional stability.

Plastics' adaptability and numerous advantages make them some of the most essential engineering materials today. BMW conserved up to 100 kg in weight after ditching metals and relying on thermoplastics and composites for the rear boot cover and front wings of its 6-Series Coupe. Without a doubt, BMW could not have taken this vibrant action without ever building prototypes and carrying out tests on them.

Not known Factual Statements About CNC Plastic Machining: Common Types Of Plastics In Use

You should proceed to develop plastic models using any machining method, right? Wrong! BMW may not inform you, however your task's success still mostly depends on the machining method you use to produce these parts and the third-party manufacturer you choose. Source covers various techniques for creating plastic prototypes, particularly CNC machining.

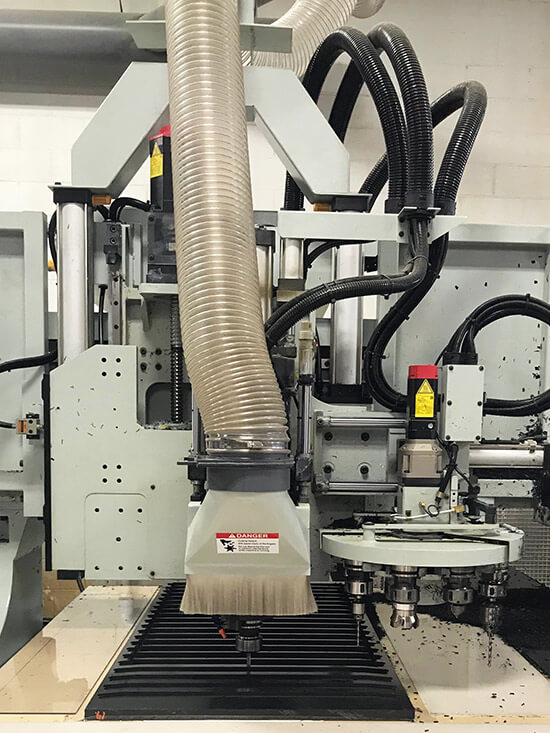

Why Would You CNC Maker Your Plastic Prototypes?CNC machining has many advantages, and here are 4 scenarios that would require CNC plastic machining. Situation No 1: Your Plastic Prototype Design Includes Tiny Details, Do you have a design that features patterns with small radii and needs tight tolerances? Then CNC machining is most likely appropriate for your project. 05 mm and tolerances as tight as 4 m. Circumstance No 2: You Need a High-Quality Surface Finish, If you're trying to produce plastic models exclusively to envision ideas or ideas, you need to consider CNC machining. It uses a premium surface area finish and does not leave layer marks common in the 3D printing procedure. It incorporates a handful of various technologies-Merged Deposition Modeling (FDM), Stereolithography.