10 Easy Facts About Rapid Prototyping Services - Online Quote - Fathom Described

from web site

The Buzz on Rapid Prototyping - Roland DG

The ability to reproduce designs from a dataset has actually provided rise to problems of rights, as it is now possible to insert volumetric information from one-dimensional images. Just like More In-Depth , the computer-aided-design computer-aided manufacturing CAD -WEB CAM workflow in the standard fast prototyping procedure starts with the creation of geometric information, either as a 3D strong utilizing a CAD workstation, or 2D slices utilizing a scanning device.

To put it simply, the object must have an "inside". The model is valid if for each point in 3D space the computer system can identify uniquely whether that point lies within, on, or outside the boundary surface area of the model. CAD post-processors will approximate the application suppliers' internal CAD geometric types (e.

To acquire the needed motion control trajectories to drive the real SFF, rapid prototyping, 3D printing or additive manufacturing mechanism, the prepared geometric model is generally sliced into layers, and the pieces are scanned into lines (producing a "2D drawing" used to create trajectory as in CNC's toolpath), mimicking in reverse the layer-to-layer physical building process. [] Application areas [edit] Quick prototyping is also typically applied in software application engineering to attempt out new organization models and application architectures such as Aerospace, Automotive, Financial Services, Product advancement, and Healthcare.

An Unbiased View of A Guide to Rapid Prototyping - AndPlus

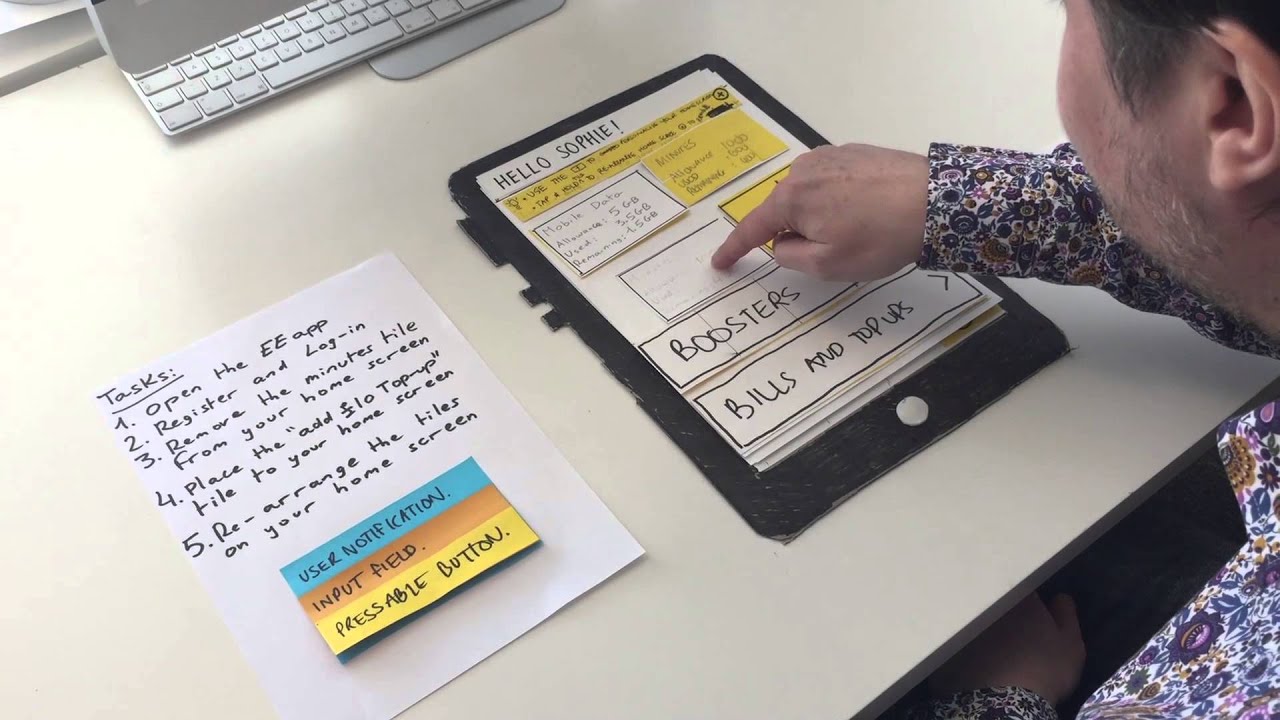

Using shanty town they can rapidly make several variations of their projects in a few days and start evaluating quicker. Quick Prototyping permits designers/developers to offer an accurate idea of how the finished item will turn out prior to putting excessive time and money into the prototype. 3D printing being utilized for Fast Prototyping enables Industrial 3D printing to take location.

History [modify] In the 1970s, Joseph Henry Condon and others at Bell Labs developed the Unix Circuit Style System (UCDS), automating the laborious and error-prone job of manually converting drawings to make circuit boards for the functions of research study and development. By the 1980s, U.S. policy makers and industrial supervisors were required to keep in mind that America's supremacy in the field of maker tool producing vaporized, in what was named the maker tool crisis.