How 3D modeling, Prototype fabrication and mass production launch can Save You Time, Stress, and Money.

from web site

The Ultimate Guide To Manufacturing Prototype & Mass Production Case Studies

Quality control observes and inspects factory production, reporting any significant quality concerns that develop. During production evaluation, a number of crucial analyses can happen, including: Process flow analysis Effectiveness of in-process testing Data collection approach verification and review Handling of unforeseen conditions Assessment of completed goods and packaging. When production is complete, the end product is examined against both the quality procedure and formerly approved samples.

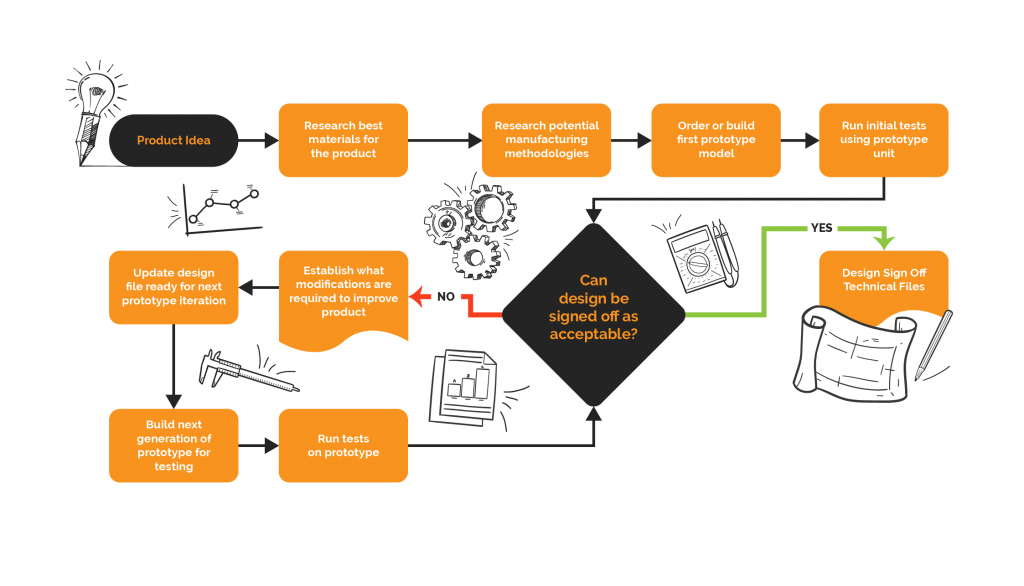

You must expect each delivery to be checked and authorized prior to being launched. Such a procedure develops a closed-loop procedure that integrates in constant enhancement for succeeding production runs. Taking an idea from idea to production is not for the faint of heart. You have actually got to have thick skin when individuals start choosing apart your idea, trying to find defects, and rest ensured your agreement producer is in organization to assist you.

More About The Difference Between a Working Prototype vsProduction

Concerns may rear their unsightly heads, in some cases causing a need to backtrack to great tune the preliminary idea or even change the scope of the job altogether. The ability to adjust to such changes on the fly and see the project through to conclusion is easier said than done, but the guidance of a skilled agreement manufacturer can help release the pressure and get you closer to that surface line a bit quicker.

These can include style, product, packaging, screening, recognition, field testing, sometimes tooling, etc. You do not want your concept getting into the marketplace 'almost' ideal - you want it right from the start.

Indicators on Precision Glass Molding from prototype to mass production You Need To Know

To help personalize your experience, the IPS website utilizes cookies.

Published By: Fieldtex Products, Inc.. This Piece Covers It Well , 2017 We have actually formerly touched on the substantial research study you need to do while choosing a Contract Manufacturing Partner, and what functions we think are most beneficial for your manufacturing process. Among the most crucial actions in the production procedure is the prototyping phase, especially if there is no pre-established prototype or design of your customized product.

MEMS Commercialization: From Prototype to Mass Production - An Overview

Fieldtex Products has one of the most reliable and forward-thinking prototype and style teams in the custom-made manufacturing industry, and our company believe that working with a maker that uses in-house model services really results in a better customized product, and more marketability for you. Here's the top factors to pick a contract making partner with prototype and style services: Even if an idea works in theory does not suggest that it will go off without a hitch.