The 2-Minute Rule for Ketron® LSG GF30 PEEK - Material Hub

from web site

The Ultimate Guide To GEHR PEEK-30GF

904 W 6th Street, Shiner, TX 77984 Terms

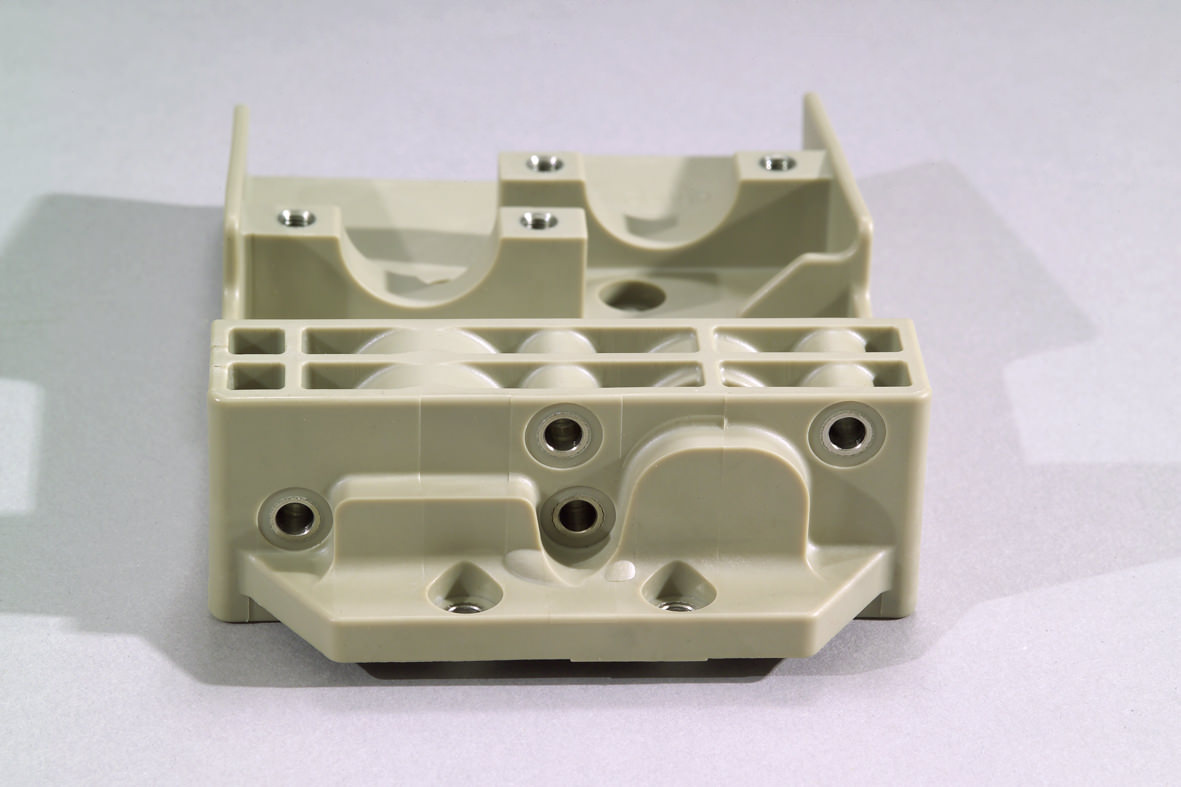

SHP PEEK GF30 Ultimate is a high-performance plastic strengthened with glass fiber. As with all our plastic derivatives, PEEK GF30 Ultimate uses the exact same performance attributes as our standard material, PEEK 450G, however with the addition of glass fiber, the efficiency qualities increase even further. GF30 integrates high rigidity with exceptional dimensional stability to provide extremely high stiffness and improved durability.

Machining requires tipped tooling due to the plastics glass fibre content. Material Advantages GF30 provides excellent efficiency characteristics, that include: High Rigidity and good dimensional stability Greater compression ability Higher constant service temperature Extremely high stiffness and Improved toughness Best high fixed load over extended periods at heat Less ideal for bearing and wear applications Motorsport Applications Applications for GF30 plastic include: Strut installs front and rear suspension Control arm linkages Equipment link bushes Fuel line insulators Valve components Electrical components Chassis parts About Smiths HP We are a leading shareholder and provider of high-performance engineering products to the motorsport sector.

What Does PP+GF30 3D Printing Filament - Professional Glass Fiber Do?

This is a special 30% glass filled PEEK adjustment that Ensinger produces under the name TECA PEEK GF30 natural. In comparison to unfilled PEEK, this glass fiber enhanced product exhibits increased mechanical strength and high rigidness. Moreover, enhanced creep strength and dimensional stability are achieved by this glass filled PEEK. These properties make this material appropriate for use in parts which are exposed to high fixed loads over extended periods in high temperature conditions.

TECAPEEK GF30 provides exceptional chemical resistance, is insoluble in all typical solvents, and displays superior resistance to high dosages of gamma radiation. Just like all PEEK grades, PEEK GF30 integrates high thermal stability with very little thermal growth and very low wetness absorption. Similar to all Ensinger PEEK materials, we can verify that glass filled TECAPEEK GF30 natural satisfies the limitations enforced by Ro, HS Instruction 2011/65/EU Constraint of Hazardous Substances in electrical and electronic devices.

AKROTEK PEEK GF 30 natural (5047) is a 30% glass fiber reinforced medium viscosity polyetheretherketone with high tightness and strength.

The Single Strategy To Use For PEEK GF30 - Aikolon Oy

Any usage of this information falls under the rules of our disclaimer. Processing/Physical Qualities, Worth, Unit, Test Requirement, ISO Information, Melt volume-flow rate, MVR 3. 5 cm/10min ISO 1133 Temperature 360 C - Load 2. 16 kg - Melt circulation index, MFI 4. 5 g/10min ISO 1133 Temperature 360 C - Load 2.