Molding the Future: Exploring the World of Injection Molds

from web site

Welcome to the fascinating world of injection molds, where innovation and precision combine to shape the future of manufacturing. Injection molds play a vital role in the production of a wide range of products, from intricate plastic components to durable automotive parts. These molds serve as intricate blueprints that guide the process of injecting molten material into specific shapes, creating products with remarkable consistency and quality. The evolution of injection molds has revolutionized the manufacturing industry, offering efficiency, cost-effectiveness, and flexibility like never before. Whether you are a seasoned industry professional or a curious enthusiast, join us on this exploration into the intricate realm of molds for injection molding.

Types of Injection Molds

There are various types of injection molds used in the manufacturing industry. The most common type is the two-plate mold, consisting of two halves that separate to release the molded part. Another common type is the three-plate mold, which features an additional plate that allows for gating and runner systems to be separated from the part.

Family molds are another popular option, enabling the production of multiple parts simultaneously. These molds are designed with multiple cavities, increasing efficiency and reducing production costs. Insert molds, on the other hand, include metal inserts to create specific features or reinforce areas of the final product.

Complex molds, such as hot-runner molds, are used for high-volume production of intricate parts. These molds have a specialized heating system that maintains the temperature of the material as it flows through the mold, ensuring precise and consistent results. Multi-cavity molds are also commonly used for mass production, featuring multiple identical cavities to produce numerous parts in a single cycle.

Design Considerations

When designing molds for injection molding , one crucial aspect to consider is the material selection. The choice of material for the mold will directly impact the final product's quality, as different materials have varying heat resistance and durability properties.

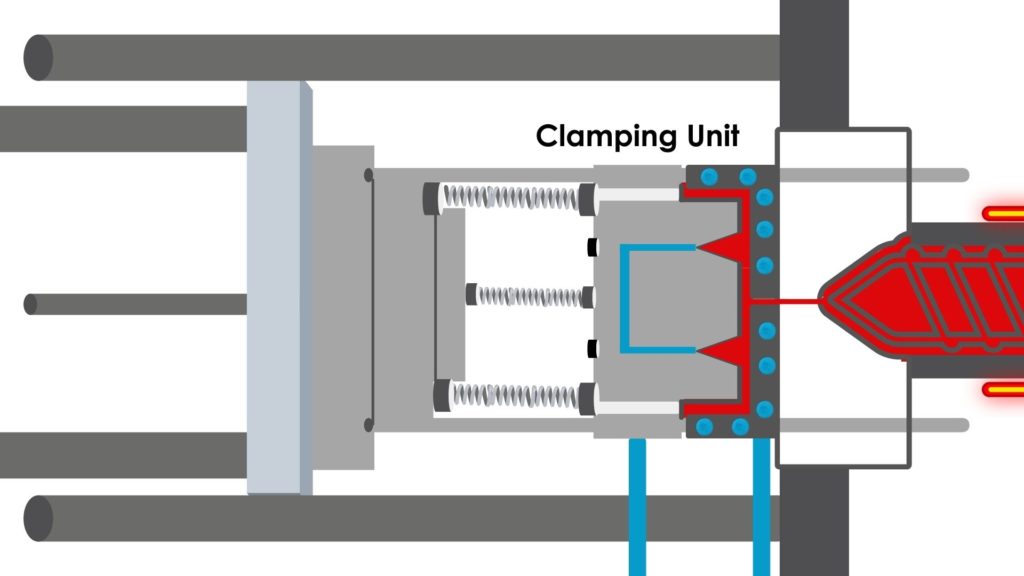

Another important factor to take into account is the cooling system design within the mold. Efficient cooling is essential to achieve shorter cycle times and maintain consistent part dimensions. Proper cooling channel placement and design can help prevent warping and ensure uniform cooling throughout the mold.

Lastly, mold venting is a critical consideration in the design process. Adequate venting helps to release air and gases trapped during the injection process, preventing defects like burn marks or air bubbles on the final product's surface. Careful vent placement and sizing are key to achieving high-quality injection molded parts.

Advancements in Injection Molding

One area of significant progress in the realm of injection molds is the development of more advanced materials. Engineers are now experimenting with cutting-edge polymers and metal alloys that offer enhanced durability and heat resistance, resulting in molds that can withstand prolonged use and high temperatures without degrading.

Another key advancement lies in the realm of digital technologies. With the integration of sophisticated software and automation systems, manufacturers can now design and produce molds with unprecedented precision and efficiency. This has led to a reduction in production times and costs, allowing for faster turnaround and more economical manufacturing processes.

Additionally, the introduction of innovative techniques such as 3D printing has revolutionized the way molds are prototyped and manufactured. This technology allows for rapid iteration and customization, enabling manufacturers to quickly test and refine mold designs before committing to full-scale production. As 3D printing continues to evolve, it is poised to further streamline the injection molding process and drive even greater efficiency in the industry.