Building Bridges: The Use of Scaffolding in Framework Projects

from web site

Preventing Usual Scaffolding Errors: Best Practices

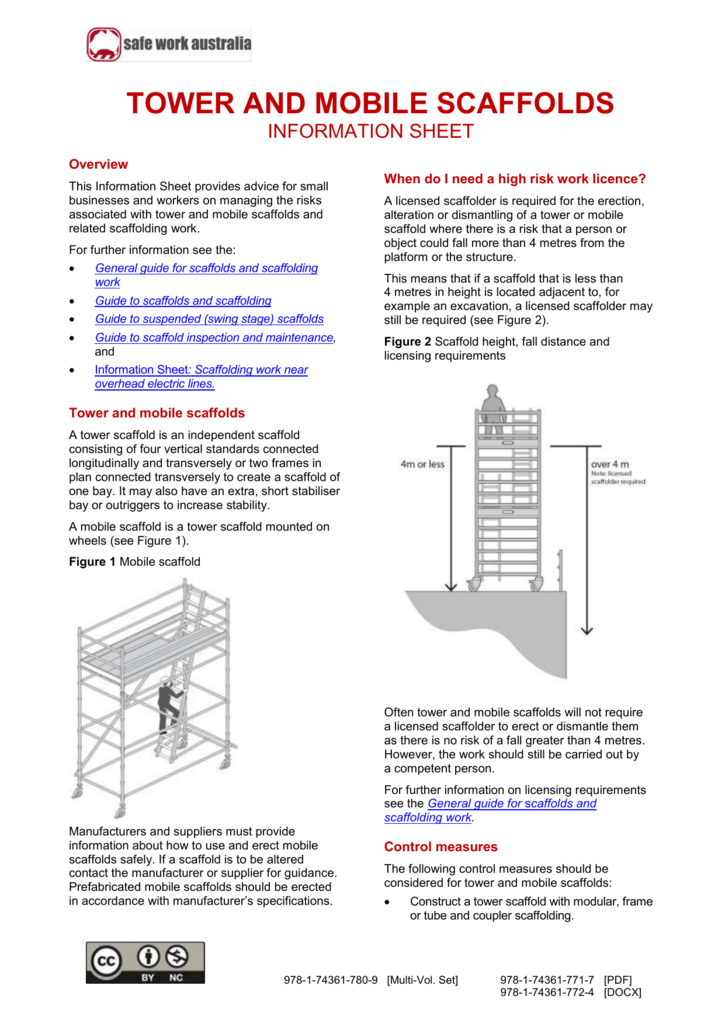

To stay clear of typical scaffolding mistakes, follow ideal techniques: plan carefully for safety and security and effectiveness, choose high-quality products like steel or aluminum, guarantee safe setting up utilizing appropriate fastening techniques, give extensive worker training on safe practices, carry out loss avoidance measures like guardrails, and observe laws via normal evaluations and documents. Proper planning, product choice, assembly, employee training, precaution, and conformity with regulations are essential. scaffolding planning & design This succinct guide highlights essential steps in scaffold security.

Significance of Correct Scaffolding Preparation

Reliable scaffolding planning is crucial for ensuring the security and efficiency of construction tasks. Proper design and reliable use of scaffolding are crucial elements that should be considered throughout the preparation phase. Correct layout involves developing an in-depth layout that considers the certain demands of the job, including the height, weight capacity, and load-bearing abilities required. By ensuring the scaffolding is designed correctly from the beginning, possible dangers and safety and security risks can be reduced.

Reliable use scaffolding includes using the framework in a way that takes full advantage of productivity while keeping safety and security standards. This includes making certain that the scaffolding is set up according to the maker's guidelines and industry policies. Proper training of employees on how to utilize the scaffolding appropriately is also necessary to stop mishaps and injuries on the building and construction site. Additionally, routine assessments and upkeep of the scaffolding are essential to recognize any type of problems early and address them promptly.

Picking the Right Scaffolding Products

Choosing the appropriate scaffolding products is an essential choice that significantly influences the safety and security and effectiveness of building and construction tasks. Appropriate upkeep and product option are essential variables to contemplate when selecting the right scaffolding materials.

When it pertains to material option, it is important to choose top notch products that fulfill security criteria. Steel and light weight aluminum prevail selections because of their toughness and stamina. Steel scaffolding is durable and ideal for durable tasks, while light weight aluminum scaffolding is lightweight and corrosion-resistant, excellent for tasks requiring regular setting up and disassembly.

Proper maintenance of scaffolding products is vital to ensure their durability and safety and security. Regular examinations should be performed to identify any kind of signs of deterioration, rust, or damage. Any damaged elements ought to be fixed or changed without delay to avoid accidents on the building site.

Making Certain Secure Scaffold Setting Up

To guarantee safe and secure scaffold setting up, it is vital to follow a precaution list, conduct correct devices examinations, and utilize safe and secure attaching methods.

These methods are vital in preserving a secure workplace and preventing mishaps or injuries on construction websites.

Precaution List

Making certain a protected scaffold assembly needs precise attention to safety measures throughout each step of the building process. Safety training plays an essential duty in gearing up employees with the knowledge to identify possible threats and execute correct safety methods.

Before commencing job, making certain that all personnel included have gone through comprehensive safety and security training is vital to prevent mishaps and injuries. In addition, complete tools evaluation prior to scaffold setting up is important to verify that all parts are in great condition and fulfill safety and security requirements.

Consistently examining tools, products, and the scaffold structure itself can assist determine any kind of prospective risks and make certain a risk-free workplace for all workers associated with the setting up process.

Appropriate Equipment Assessment

Checking the equipment completely prior to scaffold assembly is an important action in making sure a safe work environment for all personnel included. To assure tools safety and appropriate capability, follow these inspection treatments:

Visual Exam: Look for any kind of noticeable damage, corrosion, or missing parts on all elements.

Functional Testing: See to it that systems such as locking pins and adjustable components are functioning correctly. https://ilfordscaffolding.co.uk/index.html

Tons Capacity Verification: Validate that the scaffold can securely support the desired weight by evaluating manufacturer specifications and capability labels.

Following these assessment treatments is crucial in keeping a safe scaffolding configuration. By focusing on equipment safety and security via thorough assessments, the danger of crashes and injuries can be considerably reduced.

Secure Attachment Techniques

Keeping a secure scaffold setting up counts greatly on implementing specific and dependable fastening strategies. Attaching stability is vital to ensure the security and stability of the scaffold framework.

Protected links in between various scaffold elements, such as frames, braces, and systems, are vital to protect against crashes and structural failings. Utilizing suitable bolts and following manufacturer standards for tightening torque specifications are vital steps in attaining a durable scaffold setting up.

Evaluating attachments consistently for indications of wear, rust, or helping to loosen is also vital to promote the integrity of the scaffold. By focusing on fastening stability and making certain safe connections throughout the scaffold, construction teams can significantly reduce the threats connected with scaffold assembly and usage.

Regular Evaluation and Upkeep Procedures

Regular examination and upkeep procedures are important aspects of guaranteeing scaffold safety. Set up assessments assist identify prospective concerns prior to they escalate, while timely repair work attend to any kind of worries quickly.

Documents of these treatments is important for regulatory conformity and maintaining a safe workplace.

Arranged Inspections for Safety And Security

To ensure the safety and long life of scaffolding structures, crucial checks and timely upkeep are important techniques. Applying a thorough safety audit and adhering to a strict evaluation timetable are essential components in guaranteeing the architectural honesty of scaffolding.

Here are 3 essential actions to consider:

- Conduct routine safety and security audits to analyze potential dangers and conformity with safety standards.

- Establish a detailed evaluation timetable that describes when and how inspections will certainly be carried out.

- Train workers responsible for assessments to determine security issues and perform required maintenance jobs without delay.

Motivate Repairs When Required

Analyzing scaffolding routinely for security is critical to promptly resolve any repairs needed to maintain structural stability. Prompt fixings are needed to assure the security of employees and the stability of the structure. Establishing routine maintenance timetables can assist in identifying prospective problems at an early stage.

Regular examinations ought to consist of checking for loose bolts, harmed components, or any kind of signs of wear and tear. Any type of determined troubles ought to be fixed promptly by certified personnel to prevent crashes or structural failings. Maintaining detailed records of maintenances can help in tracking the scaffolding's condition in time.

Documentation for Conformity

Applying a detailed documents system for compliance with regular assessment and maintenance treatments is important for guaranteeing the security and architectural honesty of scaffolding. To accomplish this, take into consideration the following:

Regular Inspections: Conduct scheduled inspections to determine any kind of issues promptly.

Maintenance Records: Maintain in-depth records of upkeep activities and repair work.

Security Training Documentation: Make sure all personnel involved in scaffolding work have obtained proper safety and security training and preserve documents to show conformity.

Educating Employees on Safe Scaffolding Practices

Proper training of workers on safe scaffolding practices is important to assure a protected working environment on building and construction websites. Employee supervision plays a vital function in making sure that workers stick to safety and security protocols when working with scaffolding. Safety and security training ought to cover appropriate assembly and disassembly of scaffolding, appropriate fitting of guardrails and toe boards, risk-free handling of products on raised systems, and treatments to prevent drops. It is crucial that workers are skilled in acknowledging possible hazards, such as unpredictable ground conditions, overhanging high-voltage line, or harsh weather condition, and know how to reduce these threats efficiently.

Regular safety and security meetings and correspondence course can aid enhance the relevance of safe scaffolding methods and keep workers notified regarding any kind of updates in safety and security regulations. Companies ought to also supply accessibility to personal protective devices (PPE) and guarantee that employees are learnt its proper usage. By focusing on comprehensive safety training and continuous worker guidance, building firms can lower the possibility of scaffolding crashes and create a more secure workplace for all workers entailed.

Conformity With Scaffolding Rules

To guarantee a protected working environment on building and construction sites, strict adherence to scaffolding policies is crucial. Regulative compliance and safety standards must go to the center of every construction project to mitigate risks and ensure the health of workers.

Right here are three bottom lines to consider relating to conformity with scaffolding policies:

Regular Assessments: Conduct regular examinations of the scaffolding framework to recognize any potential dangers or problems that could endanger its stability. Evaluations must be executed by qualified specialists and documented as necessary.

Training and Qualification: Make certain that all employees working with or around scaffolding are effectively educated and licensed to do so. This consists of understanding safety protocols, appropriate setting up, and taking apart treatments, along with emergency feedback actions.

Documentation and Record-Keeping: Preserve in-depth records of evaluations, training qualifications, and any type of alterations made to the scaffolding. Documentation not just shows governing compliance yet additionally functions as a useful source for future recommendation and renovation.

Often Asked Questions

What Are Some Common Blunders to Stay Clear Of When Dismantling Scaffolding?

When dismantling scaffolding, it is important to utilize appropriate method to prevent crashes. Normal equipment maintenance is important for secure operations. Sticking to these techniques assures a safe workplace and decreases dangers.

How Can Weather Condition Issues Impact the Safety of Scaffolding Frameworks?

Weather condition influences can substantially influence the safety and security of scaffolding frameworks. Rainfall can endanger architectural security, bring about possible collapse. Monitoring weather conditions and taking required safety measures, such as safeguarding the scaffolding, are essential to keeping a safe workplace.

Exist Particular Guidelines for Using Scaffolding on Uneven or Sloped Surfaces?

When dealing with unequal or sloped surfaces, security worries are extremely important. Comply with details standards for correct setup, making sure security preventative measures remain in place. Regular devices upkeep is essential to maintain stability and prevent crashes in such circumstances.

What Should Be Done if an Employee Encounters a Safety And Security Concern While Making Use Of Scaffolding?

If an employee comes across a safety and security problem while making use of scaffolding, they ought to right away stop work, report the problem to their manager adhering to the reporting procedure, and if essential, trigger the emergency feedback procedure to ensure every person's safety.

Exactly How Typically Should Scaffolding Devices Be Replaced or Upgraded to Make Certain Safety And Security?

Scaffolding equipment need to be replaced according to an established routine based on supplier standards and use frequency. Upgrading regularity should align with technical developments. Normal assessments and correct upkeep are crucial to ensure safety and security conformity.

Verdict

To summarize, correct scaffolding preparation is vital. This consists of selecting appropriate materials, ensuring protected assembly, performing regular examination and maintenance, training employees on safe methods, and making certain compliance with guidelines. By complying with these best methods, the risk of accidents and injuries can be considerably lowered, developing a much safer workplace for all people involved in scaffolding operations.

This extensive approach to scaffolding safety stresses the relevance of detailed preparation, reliable interaction, and recurring vigilance in preserving a safe and secure work environment.