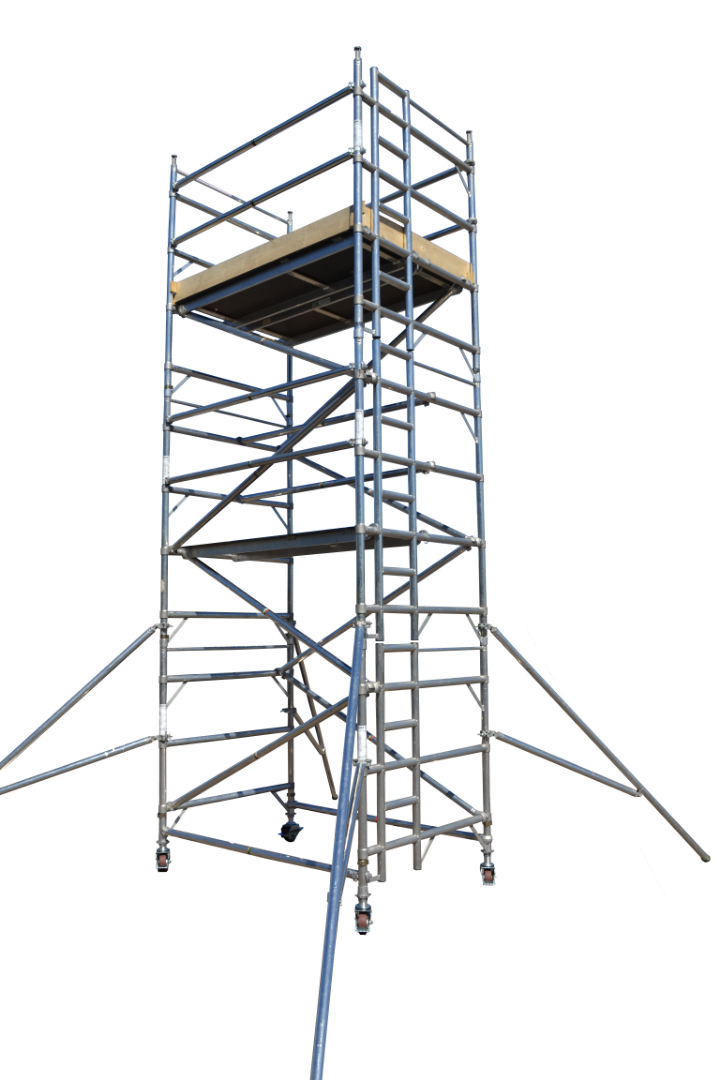

From Scaffold Tower Rentals to Permanent Installations: Your Alternatives Discussed

from web site

Scaffold Dismantling Safety And Security: Treatments to Adhere to

To guarantee scaffold taking down safety and security, conduct detailed pre-dismantling assessments checking for damages and stability. Safe and secure devices and devices appropriately with normal checks and organized storage space. Clear the work area to prevent risks, established cleaning procedures, and make use of the appropriate tools for taking apart steps. Examine post-dismantling honesty, review the ground, and execute precaution strictly. Complying with these treatments is important for employee security. Comprehending each action in the dismantling procedure is key for effective and secure scaffold dismantling.

Pre-Dismantling Examination

Prior to commencing the taking apart procedure, what key aspects should be inspected during the pre-dismantling phase to guarantee security and efficiency? One pivotal aspect is conducting a detailed safety check to make sure that all safety and security procedures remain in place and operating correctly. This includes checking out guardrails, toeboards, and personal protective devices to prevent falls and other crashes during the taking apart process.

Another vital aspect to consider during the pre-dismantling phase is assessing the architectural stability of the scaffold. It is essential to inspect the scaffold components for any type of indicators of damages or wear that can endanger its stability. https://teddingtonscaffolding.co.uk/index.html This consists of monitoring for corrosion, rust, or any deformities that might weaken the scaffold framework.

Safeguarding Devices and Equipment

To guarantee the safety and efficiency of the scaffold dismantling process, it is important to safely store and organize all tools and equipment utilized during the procedure. Correct storage space and equipment maintenance are vital consider making sure a smooth and hazard-free dismantling process. Here are some necessary actions to adhere to:

Assign certain storage locations: Appoint dedicated places for every device and devices product to stop clutter and complication. This technique aids in very easy gain access to and reduces the risk of locating spread tools.

Utilize device belts or bags: Urge employees to use device belts or pouches to lug crucial hand tools. This not just maintains tools secure yet also enables hands-free motion on the scaffold.

Implement routine tools checks: Conduct routine inspections to make sure that all devices remain in excellent functioning condition. Any damaged or malfunctioning equipment should be promptly repaired or replaced to avoid accidents.

Safe and secure loose devices: Usage lanyards or tethers to secure equipment that positions a danger of dropping from heights. This precaution decreases the danger of devices going down and triggering injuries to employees listed below.

Clearing the Workspace

Ensuring a clutter-free and organized workspace is necessary prior to starting the scaffold taking apart process to improve security and efficiency. Site preparation is important in this stage to assure a hazard-free setting for workers. Before beginning the taking down process, safety and security precautions have to be strictly abided by, consisting of the evaluation of the work area for any kind of potential risks.

Debris elimination plays an essential role in preserving a risk-free work environment. Clean-up procedures ought to be established and followed diligently to stop accidents caused by slipping or tripping over materials. Appropriate disposal approaches ought to be applied to throw away particles securely and successfully.

Methodical Taking Down Process

Executing a methodical approach is necessary for the safe and effective dismantling of scaffolds on building sites. By adhering to details actions, employees can assure a smooth and protected procedure while taking apart scaffolding structures. To achieve this, the following methods are recommended:

Check the Scaffold: Before starting the dismantling process, check out the scaffold for any type of damages or wear that can threaten its integrity. Address any type of problems found before continuing.

Get rid of Debris: Clear the scaffold of any type of devices, materials, or debris that could present a danger throughout taking apart. Keeping the workspace tidy enhances safety and guarantees an effective operations.

Comply with Sequence: Take apart the scaffold in the reverse order of its assembly, complying with the producer's guidelines. This methodical method decreases the danger of accidents and makes certain a methodical break down.

Use Correct Devices: Use suitable tools and devices for each taking down task. This practice promotes risk-free methods and adds to a reliable operations.

Sticking to these secure practices and keeping an efficient process is vital for the effective taking down of scaffolds on building sites.

Post-Dismantling Assessment

After completing the taking apart process of scaffolds on building and construction websites, a detailed post-dismantling evaluation needs to be performed to examine the architectural stability and security of the taken down locations.

The examination process includes analyzing the problem of the ground where the scaffold was positioned, looking for any kind of potential damage to the surrounding frameworks, and making certain that all debris has been appropriately removed to avoid hazards. Safety procedures have to be purely adhered to during this analysis to alleviate dangers to workers and various other employees around.

It is important to validate that no parts were left behind that can present a risk, such as loose fittings or unpredictable components. Additionally, performing a last examination to confirm that all precaution have actually been applied according to regulations is crucial.

Regularly Asked Concerns

What Are the Repercussions of Not Adhering To Proper Scaffold Taking Apart Procedures?

Not complying with appropriate scaffold taking down procedures can result in extreme safety dangers, such as drops and injuries. Furthermore, there are lawful implications, consisting of penalties or charges for non-compliance with security regulations. It is vital to focus on security methods.

Exist Any Type Of Certain Training Requirements for Workers Associated With Scaffold Dismantling?

Worker training for scaffold dismantling is important to ensure safety and security. Details training requirements consist of recognizing taking apart treatments, identifying hazards, and making use of correct equipment. Safety preventative measures must be complied with faithfully to stop accidents and injuries.

Just How Commonly Should Scaffolds Be Evaluated for Potential Taking Apart?

The frequency of inspection for scaffolds prior to taking down must align with policies and market ideal techniques to guarantee safety and security. Applying thorough evaluations regularly, while sticking to security precautions, helps minimize risks and promotes a secure work environment.

What Should Be Performed With Harmed Scaffold Elements After Taking Down? https://teddingtonscaffolding.co.uk

After dismantling, damaged scaffold parts should be appropriately analyzed for salvage options. If salvage is unrealistic, take into consideration reusing options to dispose of the materials sensibly. Prioritizing security and ecological consciousness is essential in these techniques.

Exist Any Rules or Standards Concerning the Disposal of Scaffolding Products After Taking Down?

Disposal regulations and waste management guidelines exist to address the ecological effect of scaffolding materials post-dismantling. Reusing options deal lasting options for taking care of scaffold parts, making certain compliance with policies and advertising accountable waste management techniques.

Conclusion

To sum up, sticking to correct scaffold taking down treatments is vital to guarantee the safety and security of employees and avoid accidents.

By performing a pre-dismantling examination, protecting tools and devices, getting rid of the workspace, complying with a methodical dismantling process, and conducting a post-dismantling evaluation, possible risks can be identified and mitigated.

It is essential to comply with these standards to preserve a risk-free workplace and protect against injuries.