Molding the Future: Unveiling the World of Injection Molder Technology

from web site

Injection molders are at the forefront of manufacturing innovation, revolutionizing how products are made across various industries. These sophisticated machines play a crucial role in the production process by shaping molten materials into intricately designed molds with precision and efficiency. By harnessing the power of technology, injection molder s have opened up a world of possibilities, enabling manufacturers to create high-quality products at scale in a cost-effective manner. Whether it's crafting intricate components for the automotive industry or producing consumer goods with intricate details, injection molders have become indispensable in shaping the future of manufacturing.

History of Injection Molder Technology

Centuries ago, the concept of molding materials into specific shapes dates back to ancient civilizations. However, modern Injection Molder Technology has truly revolutionized the manufacturing industry. With the development of specialized machinery, the injection molding process became more efficient and precise, leading to mass production capabilities.

The roots of Injection Molder Technology can be traced back to the late 19th century, when the first injection molding machine was patented. This marked a major milestone in industrial manufacturing, paving the way for a more streamlined and automated production process. As technology advanced, injection molders evolved to accommodate different materials and intricate designs, expanding the possibilities in various industries.

In the mid-20th century, injection molders experienced significant advancements with the introduction of computer-aided design and automation technologies. These innovations allowed for greater precision, repeatability, and customization in molding processes. Today, Injection Molder Technology continues to be at the forefront of manufacturing, driving innovation and shaping the future of production processes.

Key Components of an Injection Molding Machine

One vital component in an injection molding machine is the hopper, where raw materials are stored before being fed into the machine for processing. The hopper plays a crucial role in ensuring a consistent flow of material into the machine during the molding process.

Another essential component is the barrel, which is responsible for heating and mixing the raw material to form a molten liquid that can be injected into the mold cavity. The barrel must maintain precise temperature control to ensure the material is melted uniformly and consistently.

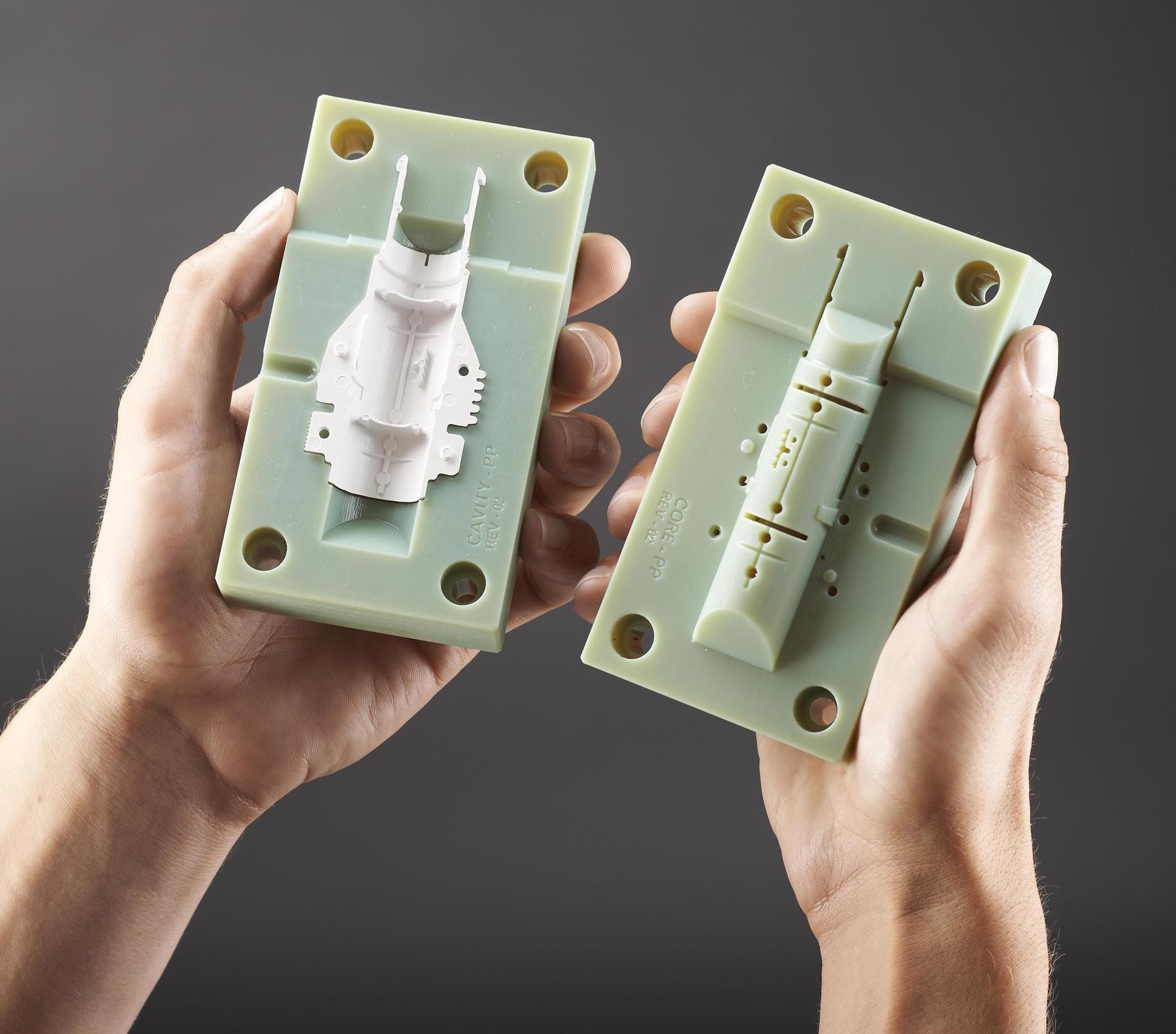

The mold cavity is where the molten material is injected to take the shape of the desired product. The design and condition of the mold cavity directly impact the quality and precision of the final product, making it a critical component in the injection molding process.

Advancements in Injection Molder Technology

In recent years, advancements in injection molder technology have revolutionized the manufacturing industry. These innovations have significantly increased efficiency and precision in the production process, leading to higher quality end products within shorter timeframes.

One key advancement is the development of more intelligent and automated injection molding machines. These cutting-edge systems are equipped with sensors and software that can monitor and adjust various parameters in real-time, ensuring consistent part quality and reducing the risk of defects.

Furthermore, the integration of additive manufacturing techniques with injection molding has opened up a world of possibilities in creating complex geometries and customized parts with enhanced performance characteristics. This hybrid approach facilitates rapid prototyping and iteration, enabling manufacturers to bring new products to market faster than ever before.