Revolutionizing Manufacturing: Exploring the Diverse Applications of Injection Molding

from web site

Welcome to an exploration of the transformative world of injection molding applications. Injection molding is a versatile manufacturing technique that has revolutionized various industries by enabling the production of complex and high-precision parts with efficiency. From automotive components to consumer products, the diverse applications of injection molding continue to push the boundaries of innovation and design.

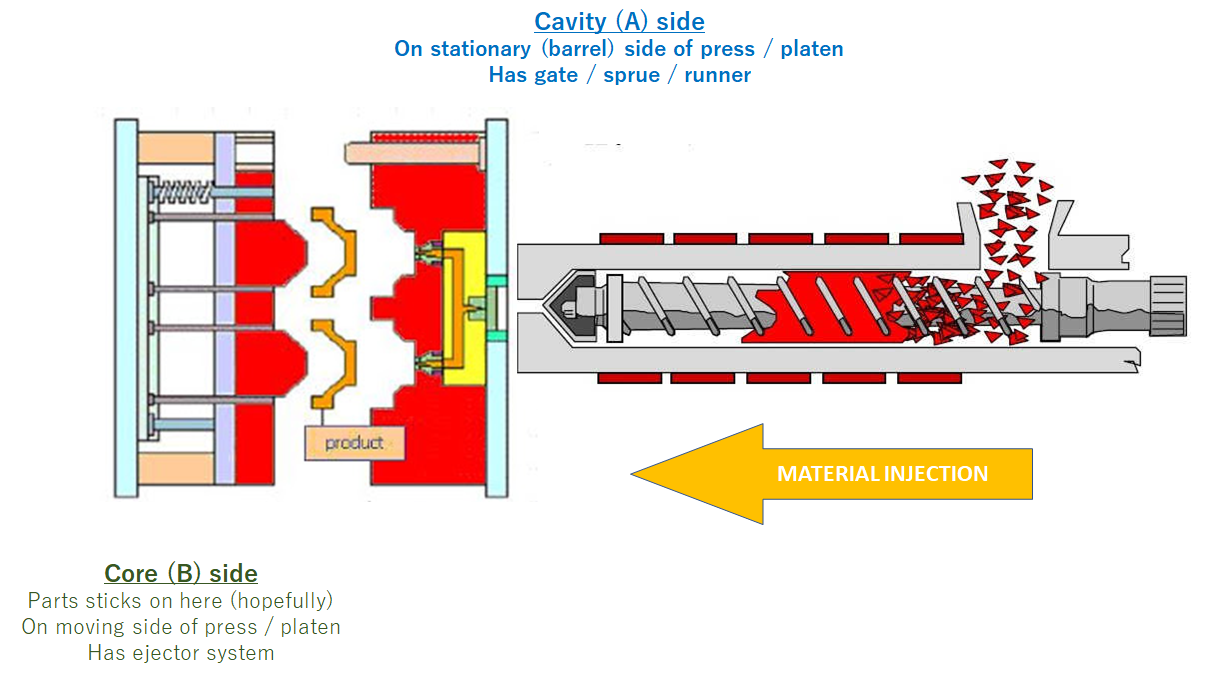

With the ability to create intricate shapes and unique designs, injection molding has become a go-to solution for manufacturers seeking cost-effective and scalable production methods. This process involves injecting molten material into a mold cavity, allowing for the rapid and repeatable production of parts with minimal waste. As technology advances, injection molding continues to evolve, offering new possibilities for customization and mass production across a wide range of industries.

History of Injection Molding

Injection molding, a transformative manufacturing process, has a rich history dating back to the 19th century. It all began in the late 1800s when John Wesley Hyatt developed the first injection molding machine to produce billiard balls. This marked a significant milestone in the world of manufacturing, introducing a more efficient and precise method for creating complex shapes.

Over the years, injection molding technology continued to evolve, leading to advancements in materials and machine designs. In the 20th century, the process gained widespread popularity in various industries due to its ability to mass-produce high-quality parts with minimal waste. Manufacturers embraced injection molding for its versatility, speed, and cost-effectiveness, revolutionizing the way products are made.

Today, injection molding plays a vital role in numerous sectors, from automotive and medical to consumer goods and electronics. The process has become increasingly sophisticated, with innovations in mold making, automation, and material science driving continuous improvements in efficiency and product quality. As we delve deeper into the diverse applications of injection molding, it is essential to understand the historical context that laid the foundation for its widespread adoption.

Innovations in Injection Molding Technology

One notable innovation in the field of injection molding technology is the development of multi-material injection molding processes. Manufacturers can now create products with multiple material properties in a single mold, resulting in enhanced functionality and cost-efficiency.

Another advancement is the integration of Industry 4.0 technologies, such as IoT sensors and data analytics, into injection molding machines. This allows for real-time monitoring of the manufacturing process, leading to improved quality control and production efficiency.

Additionally, innovations in mold design software have enabled more complex and intricate mold geometries, leading to the production of highly detailed and precise parts. Computer simulations now play a crucial role in optimizing mold design before physical production, reducing time and costs.

Environmental Impact and Sustainability

Injection molding plays a crucial role in enhancing environmental sustainability through the efficient use of materials and energy. By optimizing the manufacturing process to minimize waste and energy consumption, companies can significantly reduce their carbon footprint. Additionally, the ability to recycle and reuse materials in injection molding further contributes to environmental conservation efforts.

One key advantage of injection molding is its ability to produce intricate and complex parts with minimal material waste. This process results in higher efficiency compared to traditional manufacturing methods, where excess material often goes unused. By maximizing material utilization, injection molding helps to reduce overall environmental impact and promote sustainable practices within the manufacturing industry.

Furthermore, the durability and longevity of products manufactured using injection molding contribute to sustainability goals by extending the lifespan of end-use items. By producing high-quality, long-lasting components, manufacturers can reduce the frequency of replacement cycles and prevent unnecessary waste from entering landfills. This focus on durability not only benefits the environment but also aligns with consumer demands for environmentally conscious products.