Shaping the Future: Innovative Ways Molds Transform Plastic Manufacturing

from web site

In the realm of manufacturing, the role of molds for plastic has become increasingly significant, revolutionizing the way products are designed and produced. As industries strive for efficiency, precision, and sustainability, innovative molding techniques have emerged, showcasing the versatility and potential of plastic materials. From everyday items to complex components, molds are the backbone of modern plastic manufacturing, enabling the creation of intricate designs that would be impossible to achieve through traditional methods.

As technology advances, creative approaches to molding are transforming the landscape of production. 3D printing, for instance, is reshaping how molds are made, allowing for rapid prototyping and customized designs that meet specific needs. This innovation not only speeds up the manufacturing process but also reduces waste, making it an eco-friendly option. Additionally, advancements in materials science have led to the development of new types of plastics that enhance durability and performance, further expanding the possibilities of what can be achieved with molds in the plastic industry.

Advancements in Mold Technology

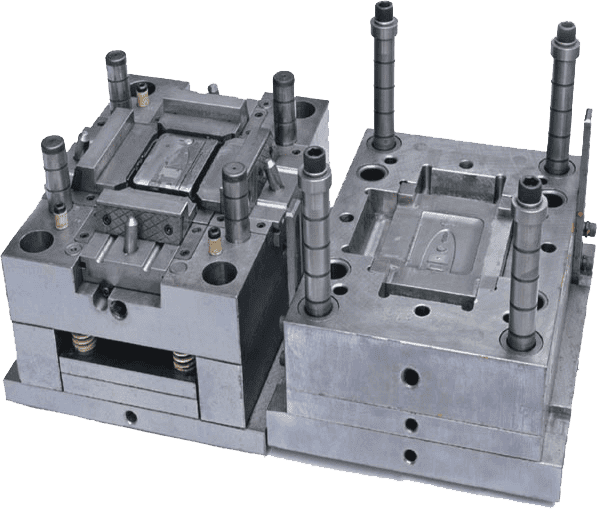

The evolution of mold technology has significantly enhanced the efficiency and precision of plastic manufacturing. Innovative designs and materials have allowed molds to be more durable and resistant to wear, which not only improves production speeds but also ensures that the final products maintain high-quality standards. For instance, the introduction of advanced steel alloys and surface treatments has enabled manufacturers to create molds that can withstand the high pressure and temperatures associated with plastic injection molding.

Additionally, the integration of computer-aided design (CAD) and computer-aided manufacturing (CAM) has revolutionized how molds are designed and produced. These technologies facilitate the creation of complex geometries and intricate details that were previously unattainable. This level of precision is crucial for producing components in industries like automotive and consumer electronics, where even minor imperfections can lead to product failure. Furthermore, the use of simulation software allows manufacturers to optimize mold designs before physical production, reducing waste and streamlining the manufacturing process.

The rise of 3D printing technology has also made a significant impact on mold creation. Designers can now rapidly prototype molds using 3D printing, which enables faster iterations and adjustments based on testing and feedback. This technology is particularly beneficial for small batch productions or customized products, where traditional mold-making processes would be too costly and time-consuming. As 3D printing continues to advance, it promises to further democratize mold-making, allowing smaller companies to compete with larger manufacturers in delivering innovative and tailored plastic solutions.

Sustainability in Plastic Molding

The push for sustainability in manufacturing has led to significant innovations in how molds for plastic are designed and utilized. molding companies near me of recycled materials, minimizing the reliance on virgin plastics. By incorporating recycled feedstocks into the molding process, manufacturers can reduce waste and lower their carbon footprint. This shift not only helps the environment but also encourages a circular economy where materials are reused instead of discarded.

Additionally, advancements in mold technology have enabled more energy-efficient production methods. Technologies such as hot runner systems and optimized injection techniques allow for reduced cycle times and minimized energy consumption. By enhancing the efficiency of the molding process, manufacturers can produce higher quantities of products while using less energy, contributing to a greener manufacturing landscape. This efficiency not only aids in cost reduction but also aligns with global sustainability goals.

Moreover, companies are exploring bioplastics as a viable option for sustainable plastic molding. These materials, derived from renewable resources, offer similar benefits to traditional plastics while reducing environmental impact. Molding bioplastics utilizes the same principles as conventional methods, making it easier for manufacturers to incorporate these sustainable alternatives. As the demand for eco-friendly products continues to rise, the integration of bioplastics in molds for plastic presents an exciting opportunity to reshape the industry towards a more sustainable future.

Future Trends in Plastic Manufacturing

As the demand for sustainable products continues to rise, the plastic manufacturing industry is increasingly focusing on eco-friendly materials and processes. Innovative molds for plastic are being designed to accommodate bioplastics and recycled materials, allowing manufacturers to create high-quality products while minimizing their environmental impact. This shift towards sustainability is driving the development of advanced mold technologies that can efficiently process new materials without compromising performance.

Automation and smart manufacturing are also shaping the future of plastic production. The integration of robotics and artificial intelligence into mold design and operation is streamlining production processes, improving precision, and reducing waste. These technologies enable real-time monitoring and adjustments during manufacturing, enhancing overall efficiency. As molds become more sophisticated, they will allow for the rapid production of complex shapes while maintaining high levels of quality control.

Lastly, the trend towards customization is transforming the landscape of plastic manufacturing. Consumers increasingly demand tailored products, prompting companies to adopt flexible mold designs capable of producing small batches of diverse items. This adaptability not only meets market demands but also encourages innovation in mold design. As manufacturers embrace these trends, molds for plastic will play a pivotal role in redefining production capabilities, driving the industry towards a more sustainable and consumer-centric future.