Versatile Applications of Foam Swabs in Electronics

from web site

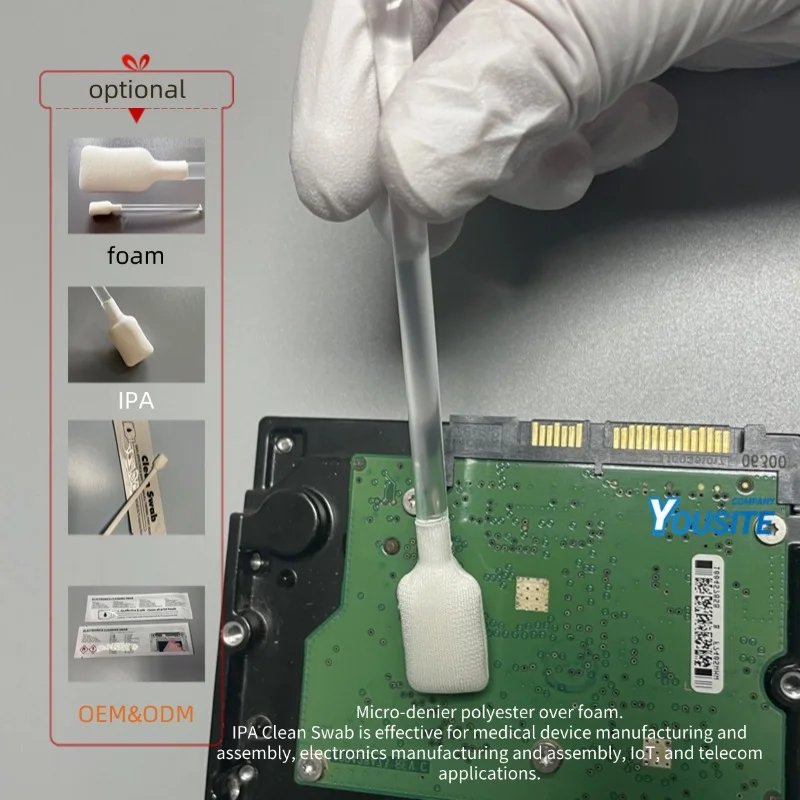

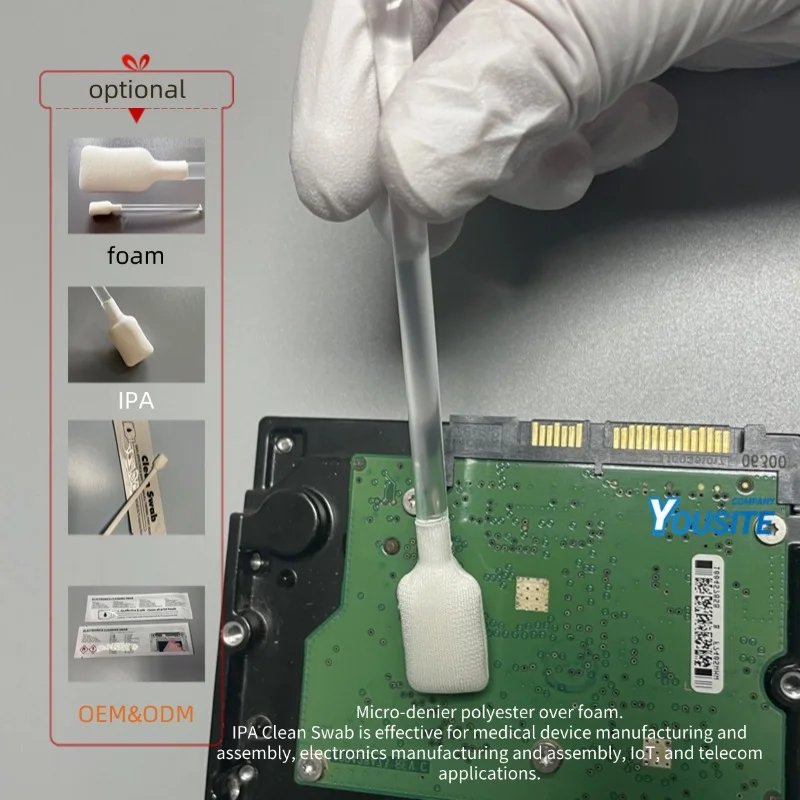

These swabs, which include foam swabs, microfiber swabs, and polyester swabs, are made to fulfill rigorous top quality criteria to ensure that they do not present any impurities into delicate atmospheres. Lint-free foam swabs provide an included advantage by guaranteeing that no fibers are left behind, preserving a beautiful cleaning procedure.

In the realm of electronics and industrial sectors, industrial swabs have actually become crucial tools for preserving tools and makers. Foam tip cleaning swabs are efficient within and cleaning difficult-to-access areas within electronic tools. Cotton swabs for cleaning electronics additionally satisfy of providing a mild yet effective cleaning remedy. Swab manufacturers continuously make every effort to improve the high quality and performance of their items, dealing with the varied demands of industries. Cotton bud manufacturers, specifically, concentrate on developing swabs that are not just absorbent but additionally possess the right texture and toughness for electronic cleaning.

In cleanroom setups, using cleanroom foam swabs prevails as a result of their compatibility with rigorous sanitation requirements. These swabs are usually used along with IPA (isopropyl alcohol) to make certain reliable cleaning and sterilization. IPA cleaning swabs are extensively understood for their capacity to liquify residues and evaporate swiftly, leaving no dampness behind. Sterile foam swabs and IPA cleanroom swabs end up being important in situations where contamination control is of utmost significance.

The sensible applications of alcohol swabs expand past cleanrooms. While alcohol swab uses in electronic and clinical contexts are well-documented, their industrial applications are just as substantial. In industrial settings, industrial cleaning swabs help in the upkeep of machinery and can be made use of for precise application of cleaning solvents or for place cleaning. Industrial cleanroom swabs are customized to endure the rigors of varied cleaning requirements while preserving their structural integrity.

The adaptability of swabs is further exemplified in printer upkeep, where printer cleaning swabs are important to making certain the longevity and efficiency of printers. Foam swabs for electronics, specifically customized for cleaning printheads and other sensitive elements, assistance in protecting against the accumulation of particles, which can hinder printer performance. Printer cleaning swabs form a vital part of printhead cleaning kits, an essential for anyone depending on printers for organization operations.

For thermal printers, specialized tools like the thermal printer cleaning pen or comprehensive printhead cleaning kits, consisting of cleaning swabs and cleaning cards, provide extensive cleaning services. Zebra cleaning cards, Magicard cleaning cards, and Evolis Primacy cleaning cards are a few of the items made to keep printers running at peak efficiency by removing dirt and deposits from their intricate parts.

The layout of cleanroom swabs accommodates different cleaning requirements. Swab styles vary from pointed tip swabs, which provide accuracy in gaps and tight rooms, to rounded, oval, and rectangular tip swabs offering protection for more comprehensive surfaces. Each design is intended at giving the ideal cleaning option based upon the application and atmosphere.

As technical innovations proceed to shape the industrial landscape, microfiber swabs have actually become an additional prominent choice because of their remarkable cleaning capacities. Lint-free microfiber tip swabs, or microfiber Q-tips, have the capability to hold and draw in dirt and particles, making them optimal for high-precision settings. Microfiber polyester swabs integrate the advantages of both polyester and microfiber, providing efficient cleaning with a low risk of contamination.

Sterile polyester swabs are used in atmospheres where sterility can not be jeopardized. These swabs are essential in clinical and laboratory settings, making certain that samples remain unpolluted. Their polyester tipped swabs provide superb chemical resistance and toughness, making them ideal for various industrial applications.

Ultimately, the globe of printer upkeep is additional streamlined with printers cleaning kits. These detailed kits frequently include products like thermal printer cleaning pens and cleaning cards designed to preserve both the printer's surface and the internal components. By making use of these kits regularly, users can stop print mistakes and prolong the life of their tools.

Cleanroom swabs, foam swabs, microfiber swabs, and industrial swabs comprise a vital part of both industrial and specialist cleaning remedies. These are not just cleaning executes; they are specifically crafted tools that make sure the stability of numerous settings, from cleanrooms in state-of-the-art manufacturing facilities to moderate household electronics cleaning tasks. Cleanroom swabs are specifically made to manage contamination by effectively recording bits and deposits that could possibly endanger delicate atmospheres like semiconductor production areas or pharmaceutical development labs.

Among these, foam swabs are prominent as a result of their functional application. Foam swabs are available in various tip shapes, such as rectangular, oval, and pointed tips. Their open-cell framework permits them to successfully soak up solutions like isopropyl alcohol (IPA) and deal lint-free cleaning, making them excellent for electronics cleaning and upkeep tasks. Whether you're handling a delicate printer element or cleaning electronic boards, foam tip swabs are crafted to stop damage while giving comprehensive cleaning.

Industrial swabs show a broad range of uses as a result of their durability and design compatibility with strenuous atmospheres. These swabs are vital in preserving the functional efficiency of hefty tools and fragile elements in sectors ranging from electronics to aerospace. Certain kinds, such as cleanroom foam swabs and IPA swabs, contribute dramatically to preserving tidiness requirements by acting as devices to apply solvents like IPA, additional making certain a sterile functioning surface with specific control over contamination levels.

For manufacturers and electronic lovers, cleanroom swabs with white or blue foam tips are very suggested for surface prep work and upkeep. Lint-free foam swabs provide superb fragment entrapment which is important in maintaining tidy areas in industrial spaces. Along with foam, microfiber swabs play an essential role many thanks to their exceptional ability to attract dirt and microparticles without scratching fragile surface areas. Microfiber q-tips provide a mild and very effective cleaning device especially suitable for ambiguous surfaces where conventional swabs can fail.

Numerous manufacturers focus on generating these innovative cleaning tools, emphasizing the layout and material specifics to meet sector criteria. Swab manufacturers innovate continuously to resolve the developing requirements of markets reliant on precision cleaning. Schedule from cotton swab manufacturers shows an expanding range in swab layout, extending from easy cotton tips for daily usage to innovative polyester-tipped swabs suited for important medical and electronic cleaning jobs.

Printer cleaning is another specific niche where swabs show their significance. Specific tools like printer cleaning swabs, printhead cleaning kits, and thermal printer cleaners are developed, attending to problems like ink build-up that can interfere with regular functionality.

The function of swabs expands right into the upkeep of vital workplace equipment. The thermal printer cleaning pen ensures your printheads remain clean and free of ink obstructions that restrain printing top quality. Similarly, specialized items like the evolis primacy cleaning card are developed to maintain card printers free of particles and impurities, prolonging the tool's life expectancy and making certain ideal efficiency.

Alcohol swab uses in industrial and cleanroom setups better prolong their utility by leveraging the sterilizing properties important like IPA to make certain contamination control. IPA cleaning swabs are liked in circumstances where rigid cleaning is paramount, as they get rid of dust, oils, and contaminants swiftly and efficiently. Sterile foam swabs equipped with IPA are indispensably made use of in settings demanding the greatest requirements of health.

Polyester swabs, consisting of those considered for sterile polyester swab uses, supply an ideal service for circumstances calling for phenomenal sanitation and contamination control. Due to their snugly injury fibers, these swabs stand out in eliminating microscopic bits without losing. Available in microfiber polyester and typical polyester frontal variations, these swabs are fit for fragile cleaning where accuracy is key.

Inevitably, whether participated in keeping the sanitation criteria of a controlled industrial environment or ensuring your thermal printers remain to generate clear, high-grade outputs, the variety and innovation in swab technology manifest their necessity in day-to-day operations and specialized uses alike. From IPA cleanroom swabs to lint-free microfiber tip products, the variety of swab choices offered offers the precise tool for exact and reliable cleaning.

In recap, swabs are important to a large selection of industries, from cleanrooms and electronics to printers and beyond. Their varied styles and structures, including foam, polyester, cotton, and microfiber swabs, fulfill different cleaning demands while adhering to no-compromise high quality requirements. Whether it's for industrial cleaning, electronic upkeep, or guaranteeing a sterile atmosphere, the appropriate option of swabs makes certain ideal tidiness and functionality, reflecting their essential function in contemporary industrial procedures.

In the realm of electronics and industrial sectors, industrial swabs have actually become crucial tools for preserving tools and makers. Foam tip cleaning swabs are efficient within and cleaning difficult-to-access areas within electronic tools. Cotton swabs for cleaning electronics additionally satisfy of providing a mild yet effective cleaning remedy. Swab manufacturers continuously make every effort to improve the high quality and performance of their items, dealing with the varied demands of industries. Cotton bud manufacturers, specifically, concentrate on developing swabs that are not just absorbent but additionally possess the right texture and toughness for electronic cleaning.

In cleanroom setups, using cleanroom foam swabs prevails as a result of their compatibility with rigorous sanitation requirements. These swabs are usually used along with IPA (isopropyl alcohol) to make certain reliable cleaning and sterilization. IPA cleaning swabs are extensively understood for their capacity to liquify residues and evaporate swiftly, leaving no dampness behind. Sterile foam swabs and IPA cleanroom swabs end up being important in situations where contamination control is of utmost significance.

The sensible applications of alcohol swabs expand past cleanrooms. While alcohol swab uses in electronic and clinical contexts are well-documented, their industrial applications are just as substantial. In industrial settings, industrial cleaning swabs help in the upkeep of machinery and can be made use of for precise application of cleaning solvents or for place cleaning. Industrial cleanroom swabs are customized to endure the rigors of varied cleaning requirements while preserving their structural integrity.

The adaptability of swabs is further exemplified in printer upkeep, where printer cleaning swabs are important to making certain the longevity and efficiency of printers. Foam swabs for electronics, specifically customized for cleaning printheads and other sensitive elements, assistance in protecting against the accumulation of particles, which can hinder printer performance. Printer cleaning swabs form a vital part of printhead cleaning kits, an essential for anyone depending on printers for organization operations.

For thermal printers, specialized tools like the thermal printer cleaning pen or comprehensive printhead cleaning kits, consisting of cleaning swabs and cleaning cards, provide extensive cleaning services. Zebra cleaning cards, Magicard cleaning cards, and Evolis Primacy cleaning cards are a few of the items made to keep printers running at peak efficiency by removing dirt and deposits from their intricate parts.

The layout of cleanroom swabs accommodates different cleaning requirements. Swab styles vary from pointed tip swabs, which provide accuracy in gaps and tight rooms, to rounded, oval, and rectangular tip swabs offering protection for more comprehensive surfaces. Each design is intended at giving the ideal cleaning option based upon the application and atmosphere.

As technical innovations proceed to shape the industrial landscape, microfiber swabs have actually become an additional prominent choice because of their remarkable cleaning capacities. Lint-free microfiber tip swabs, or microfiber Q-tips, have the capability to hold and draw in dirt and particles, making them optimal for high-precision settings. Microfiber polyester swabs integrate the advantages of both polyester and microfiber, providing efficient cleaning with a low risk of contamination.

Sterile polyester swabs are used in atmospheres where sterility can not be jeopardized. These swabs are essential in clinical and laboratory settings, making certain that samples remain unpolluted. Their polyester tipped swabs provide superb chemical resistance and toughness, making them ideal for various industrial applications.

Ultimately, the globe of printer upkeep is additional streamlined with printers cleaning kits. These detailed kits frequently include products like thermal printer cleaning pens and cleaning cards designed to preserve both the printer's surface and the internal components. By making use of these kits regularly, users can stop print mistakes and prolong the life of their tools.

Cleanroom swabs, foam swabs, microfiber swabs, and industrial swabs comprise a vital part of both industrial and specialist cleaning remedies. These are not just cleaning executes; they are specifically crafted tools that make sure the stability of numerous settings, from cleanrooms in state-of-the-art manufacturing facilities to moderate household electronics cleaning tasks. Cleanroom swabs are specifically made to manage contamination by effectively recording bits and deposits that could possibly endanger delicate atmospheres like semiconductor production areas or pharmaceutical development labs.

Among these, foam swabs are prominent as a result of their functional application. Foam swabs are available in various tip shapes, such as rectangular, oval, and pointed tips. Their open-cell framework permits them to successfully soak up solutions like isopropyl alcohol (IPA) and deal lint-free cleaning, making them excellent for electronics cleaning and upkeep tasks. Whether you're handling a delicate printer element or cleaning electronic boards, foam tip swabs are crafted to stop damage while giving comprehensive cleaning.

Industrial swabs show a broad range of uses as a result of their durability and design compatibility with strenuous atmospheres. These swabs are vital in preserving the functional efficiency of hefty tools and fragile elements in sectors ranging from electronics to aerospace. Certain kinds, such as cleanroom foam swabs and IPA swabs, contribute dramatically to preserving tidiness requirements by acting as devices to apply solvents like IPA, additional making certain a sterile functioning surface with specific control over contamination levels.

For manufacturers and electronic lovers, cleanroom swabs with white or blue foam tips are very suggested for surface prep work and upkeep. Lint-free foam swabs provide superb fragment entrapment which is important in maintaining tidy areas in industrial spaces. Along with foam, microfiber swabs play an essential role many thanks to their exceptional ability to attract dirt and microparticles without scratching fragile surface areas. Microfiber q-tips provide a mild and very effective cleaning device especially suitable for ambiguous surfaces where conventional swabs can fail.

Numerous manufacturers focus on generating these innovative cleaning tools, emphasizing the layout and material specifics to meet sector criteria. Swab manufacturers innovate continuously to resolve the developing requirements of markets reliant on precision cleaning. Schedule from cotton swab manufacturers shows an expanding range in swab layout, extending from easy cotton tips for daily usage to innovative polyester-tipped swabs suited for important medical and electronic cleaning jobs.

Printer cleaning is another specific niche where swabs show their significance. Specific tools like printer cleaning swabs, printhead cleaning kits, and thermal printer cleaners are developed, attending to problems like ink build-up that can interfere with regular functionality.

The function of swabs expands right into the upkeep of vital workplace equipment. The thermal printer cleaning pen ensures your printheads remain clean and free of ink obstructions that restrain printing top quality. Similarly, specialized items like the evolis primacy cleaning card are developed to maintain card printers free of particles and impurities, prolonging the tool's life expectancy and making certain ideal efficiency.

Alcohol swab uses in industrial and cleanroom setups better prolong their utility by leveraging the sterilizing properties important like IPA to make certain contamination control. IPA cleaning swabs are liked in circumstances where rigid cleaning is paramount, as they get rid of dust, oils, and contaminants swiftly and efficiently. Sterile foam swabs equipped with IPA are indispensably made use of in settings demanding the greatest requirements of health.

Polyester swabs, consisting of those considered for sterile polyester swab uses, supply an ideal service for circumstances calling for phenomenal sanitation and contamination control. Due to their snugly injury fibers, these swabs stand out in eliminating microscopic bits without losing. Available in microfiber polyester and typical polyester frontal variations, these swabs are fit for fragile cleaning where accuracy is key.

Inevitably, whether participated in keeping the sanitation criteria of a controlled industrial environment or ensuring your thermal printers remain to generate clear, high-grade outputs, the variety and innovation in swab technology manifest their necessity in day-to-day operations and specialized uses alike. From IPA cleanroom swabs to lint-free microfiber tip products, the variety of swab choices offered offers the precise tool for exact and reliable cleaning.

In recap, swabs are important to a large selection of industries, from cleanrooms and electronics to printers and beyond. Their varied styles and structures, including foam, polyester, cotton, and microfiber swabs, fulfill different cleaning demands while adhering to no-compromise high quality requirements. Whether it's for industrial cleaning, electronic upkeep, or guaranteeing a sterile atmosphere, the appropriate option of swabs makes certain ideal tidiness and functionality, reflecting their essential function in contemporary industrial procedures.