Safe and Secure: Top-Notch Scaffolding Solutions

from web site

Just how to Select the Right Scaffolding System for Your Task

Selecting the right scaffolding system includes analyzing job needs, taking into consideration equipment compatibility, product durability, and lots capacity. Evaluate site conditions by examining the building and construction area, dirt, and accessibility factors. Prepare an in-depth budget, carrying out cost evaluation, and checking out funding alternatives. Focus on security by sticking to policies, conducting assessments, and training workers. When it concerns choosing the scaffold, contrast steel and aluminum choices, personalize as needed, and comprehend height and lots requirements. Each action is necessary for a successful building job.

Project Needs Evaluation

When beginning a building and construction project, conducting an extensive task requirements evaluation is crucial for selecting one of the most ideal scaffolding system. Two key elements to take into account during this analysis are equipment compatibility and product resilience. Making sure that the scaffolding system works with other equipment on-site assists to improve operations and enhance total security. In addition, evaluating the material sturdiness of the scaffolding system is very important to assure its long life and integrity throughout the project period.

Another vital aspect to assess is the tons capacity of the scaffolding system. Understanding the optimum weight the scaffolding can support is important for preserving a safe working environment for building employees and preventing accidents. In addition, thinking about the platform height is essential to figure out the most effective grab completing tasks effectively and securely.

Site Examination and Preparation

Doing a comprehensive evaluation of the construction site and appropriately arranging it are crucial action in assuring the effective execution of the picked scaffolding system. Before establishing any scaffolding, performing a dirt assessment is essential to make certain that the ground can support the weight of the framework and the employees. Comprehending the dirt structure aids in identifying the sort of foundation or base plates needed to offer security and avoid crashes.

In addition, determining accessibility points is vital throughout the site examination process. Access factors need to be purposefully situated to facilitate the movement of products, devices, and workers to and from the scaffolding. Taking into consideration factors such as distance to the work area, security policies, and simplicity of access is key in enhancing process efficiency.

Budget Considerations

Cautious economic planning is important when taking into consideration spending plan considerations for picking a scaffolding system. Performing an extensive cost evaluation is important to ensure that the chosen scaffolding system lines up with the job's financial restraints. Prior to choosing, job supervisors should examine the complete price of ownership, consisting of not just the preliminary purchase or rental prices yet additionally expenditures related to installment, maintenance, taking down, and any type of prospective upgrades or modifications.

Financial planning need to likewise take into account the job timeline, as longer job periods might require scaffolding systems with higher resilience and as a result greater prices. Additionally, thinking about the prospective roi is essential, especially for projects where the scaffolding system might influence performance and performance significantly.

To enhance budget plan factors to consider, project supervisors ought to look for quotes from numerous scaffolding suppliers, compare prices structures, and bargain favorable terms. In addition, discovering funding options or rental agreements can assist expand costs over the task period, easing the economic concern. By focusing on economic planning and cost evaluation, project managers can choose a scaffolding system that satisfies project needs without compromising budget constraints.

Safety And Security and Conformity Checks

Making certain safety and compliance with industry policies is important in the choice and utilization of a scaffolding system. Safety laws are in place to secure employees and stop crashes. It is essential to comprehend and comply with these policies when picking a scaffolding system for your job.

Regular examination treatments are necessary to preserve security requirements. Assessments need to be performed before the scaffolding is used, at routine intervals throughout usage, and after any type of changes or events that can affect its stability. https://ladbrokegrovescaffolding.co.uk These evaluations assist identify any prospective dangers or weaknesses in the system that might endanger safety and security.

Educating workers on just how to properly assemble, utilize, and dismantle the scaffolding system is likewise vital for making certain security. Employees must recognize with safety and security methods and procedures to avoid accidents and injuries on-site.

Scaffolding System Selection

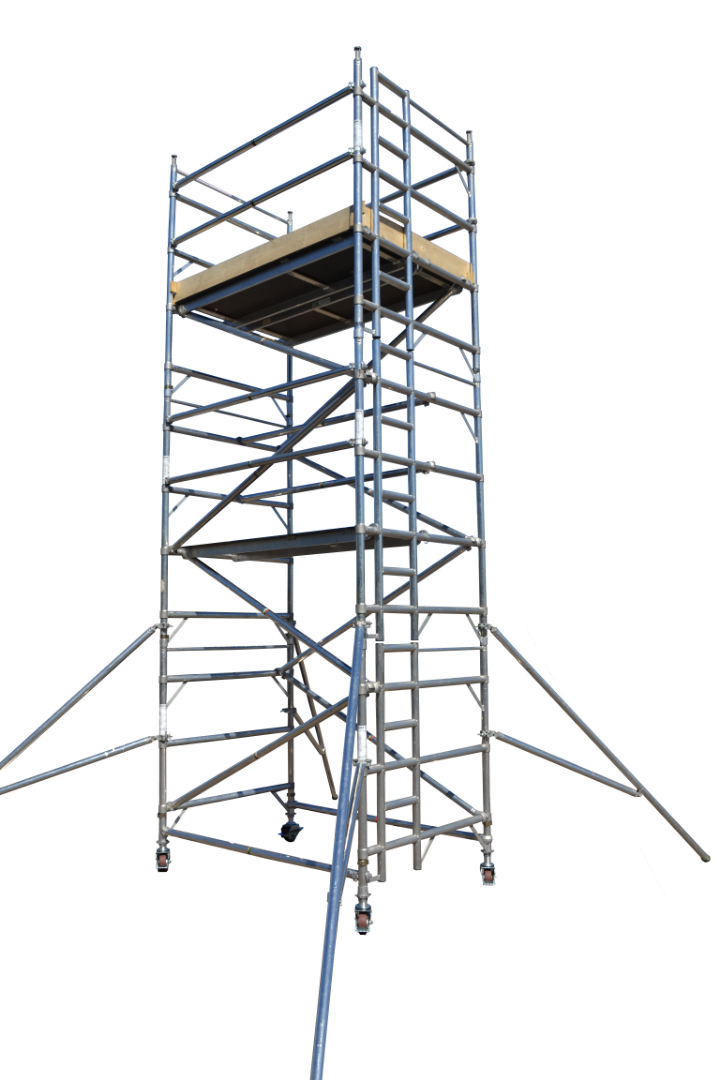

Choosing a proper scaffolding system needs comprehensive consideration of job requirements and safety criteria. When selecting a scaffolding system, it is essential to review the product options readily available. Steel scaffolding supplies robust assistance and toughness, suitable for projects needing heavy lots, while aluminum scaffolding offers a light-weight alternate suitable for jobs where flexibility is essential.

Personalization is likewise a vital aspect to resolve certain task demands. Recognizing the height requirements of the task is critical as it figures out the type and variety of systems needed. Additionally, thinking about the lots capacity of the scaffolding system is critical to make sure it can safely sustain employees, tools, and products.

Frequently Asked Questions

What Are Some Common Errors to Prevent When Utilizing a Scaffolding System?

When utilizing a scaffolding system, common mistakes to avoid include disregarding safety precautions, ignoring upkeep requirements, incorrect setting up, and inadequate inspection. Focusing on these elements is vital to making sure a secure working environment and avoiding crashes.

Exactly How Can the Weather Condition Influence the Installation and Safety of a Scaffolding System?

Wind can pose threats by destabilizing scaffolding frameworks and jeopardizing workers. Rain can create unsafe surfaces, affecting installation top quality. Safety worries develop from wind implications, while rain impact can additionally bring about installment difficulties, making weather conditions vital factors in scaffolding safety.

Are There Any Type Of Particular Training or Qualifications Called For to Use a Scaffolding System?

Training demands for scaffolding systems differ by region but typically consist of completion of a certified training program. Accreditation procedures commonly entail both theoretical expertise and useful abilities evaluations to assure risk-free and competent use the devices.

Just how Do You Determine the Maximum Weight Capacity of a Scaffolding System?

Establishing the maximum weight capacity of a scaffolding system entails evaluating its lots ability and weight circulation capacities. Comprehending these aspects guarantees that the structure can securely sustain the designated lots, advertising a protected working environment.

Can a Scaffolding System Be Easily Changed or Readjusted During a Project if Needed?

Scaffolding systems can typically be easily changed throughout a task if required due to their flexible layout and modular parts. This flexibility allows for fast changes to adapt to varying project needs efficiently.

Verdict

To summarize, choosing the appropriate scaffolding system for a task requires comprehensive analysis of project requirements, site evaluation, spending plan considerations, safety and conformity verifications, and selection of the appropriate system.

It is important to prioritize safety and security and conformity to ensure the success of the project and the well-being of workers.

By adhering to these actions, job supervisors can make informed decisions when selecting one of the most fitting scaffolding system for their details needs.