Exploring the Beauty and Durability of Cultured Travertine A Comprehensive Guide

from web site

Introduction

Travertine is a beautiful and versatile natural stone that has been used for centuries in various architectural and design applications. Known for its unique patterns and warm color tones, travertine has become a popular choice for interior and exterior spaces. In recent years, a new innovation in the stone industry has emerged - cultured travertine. This artificial stone product replicates the look and feel of natural travertine while offering enhanced durability and versatility. In this comprehensive guide, we will explore the beauty and benefits of cultured travertine, its production process, applications, maintenance, and more.

Understanding Cultured Travertine

Cultured travertine, also known as engineered or manufactured travertine, is a man-made stone product designed to mimic the appearance of natural travertine. It is composed of a blend of natural materials such as limestone, marble, and other minerals, along with resins and pigments. The manufacturing process involves mixing these materials together to create a slurry that is then poured into molds to form tiles, slabs, or other custom shapes.

One of the key advantages of cultured travertine is its consistency in color and pattern. Unlike natural stone, which can vary in appearance due to geological factors, cultured travertine offers a uniform look that can be easily matched and replicated. This makes it an ideal choice for large-scale projects where consistency is important.

Benefits of Cultured Travertine

Cultured travertine offers a number of benefits that make it a popular choice for both residential and commercial applications. Some of the key advantages of cultured travertine include:

1. Durability: Cultured travertine is engineered to be more durable and resistant to stains, scratches, and etching compared to natural stone. This makes it an ideal choice for high-traffic areas such as kitchens, bathrooms, and commercial spaces.

2. Versatility: Cultured travertine can be customized to suit a wide range of design styles and preferences. It is available in various colors, finishes, and sizes, making it suitable for both traditional and contemporary settings.

3. Cost-Effective: Cultured travertine is generally more affordable than natural stone, making it a cost-effective alternative for homeowners and designers on a budget.

4. Easy Maintenance: Cultured travertine is easy to clean and maintain, requiring only regular sweeping and occasional sealing to keep it looking its best.

Applications of Cultured Travertine

Cultured travertine can be used in a variety of applications, both indoors and outdoors. Some common uses of cultured travertine include:

1. Flooring: Cultured travertine tiles are a popular choice for flooring due to their durability and timeless appeal. They can be installed in entryways, kitchens, bathrooms, and living areas to create a warm and inviting atmosphere.

2. Countertops: Cultured travertine countertops offer a luxurious look that can enhance the beauty of any kitchen or bathroom. They are heat-resistant and easy to clean, making them a practical choice for busy households.

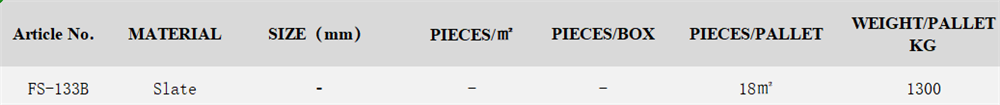

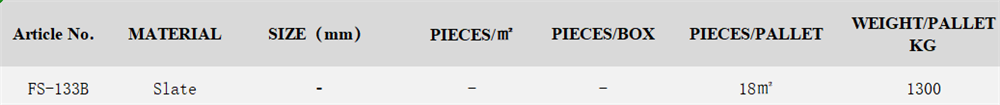

3. Backsplashes: Roofing slate and environmental impact add a touch of elegance to kitchens and bathrooms. They are available in a variety of colors and patterns to complement any design scheme.

4. Wall Cladding: Cultured travertine can be used to create stunning accent walls or feature panels in residential and commercial spaces. Its natural beauty and texture add depth and character to any room.

5. Outdoor Spaces: Cultured travertine pavers are a popular choice for patios, pool decks, and outdoor walkways. They are slip-resistant and weather-resistant, making them ideal for outdoor use.

Production Process of Cultured Travertine

The production process of cultured travertine involves several steps to create a high-quality and consistent product. Here is an overview of the typical manufacturing process:

1. Raw Materials Selection: The first step in producing cultured travertine is selecting high-quality natural materials such as limestone, marble, and other minerals. These materials are crushed into a fine powder and carefully measured to ensure the correct proportions.

2. Mixing: The crushed materials are mixed together with resins, pigments, and other additives to create a slurry with a uniform consistency. The mixture is thoroughly blended to ensure a smooth and homogenous product.

3. Molding: The slurry is poured into molds that are shaped according to the desired size and thickness of the finished product. The molds are vibrated or pressed to remove air bubbles and ensure a dense and compact material.

4. Curing: The molded pieces are left to cure in a controlled environment for a specific period of time. This allows the materials to harden and bond together, forming a strong and durable product.

5. Finishing: Once the cultured travertine has cured, it is trimmed, polished, and finished to achieve the desired texture and appearance. The surface may be honed, polished, brushed, or tumbled to create different finishes.

6. Quality Control: Before the final product is packaged and shipped, it undergoes rigorous quality control checks to ensure that it meets the highest standards of consistency and durability.

Maintenance of Cultured Travertine

Proper maintenance is essential to preserve the beauty and longevity of cultured travertine surfaces. Here are some tips for caring for cultured travertine:

1. Regular Cleaning: Sweep or vacuum cultured travertine floors regularly to remove dirt and debris. Use a mild detergent or stone cleaner to mop the floors and wipe down countertops and other surfaces.

2. Sealing: Cultured travertine should be sealed periodically to protect it from stains and moisture. Consult with a professional to determine the appropriate sealer and sealing schedule for your specific application.

3. Avoid Harsh Chemicals: Avoid using harsh chemicals or abrasive cleaners on cultured travertine, as they can damage the surface and strip away the sealer. Opt for pH-neutral cleaners that are safe for use on natural stone.

4. Prevent Scratches: Place protective pads under furniture legs to prevent scratches on cultured travertine floors. Use cutting boards and trivets on countertops to avoid scratching or etching.

5. Address Stains Promptly: Clean up spills immediately to prevent staining on cultured travertine surfaces. Blot the spill with a clean cloth and rinse the area with water to remove any residue.

Conclusion

Cultured travertine offers a versatile and durable alternative to natural stone, with a wide range of applications in residential and commercial settings. Its beauty, consistency, and ease of maintenance make it a popular choice for homeowners, designers, and architects looking to achieve a timeless and elegant look. By understanding the production process, benefits, applications, and maintenance of cultured travertine, you can make an informed decision when choosing this innovative stone product for your next project.

Travertine is a beautiful and versatile natural stone that has been used for centuries in various architectural and design applications. Known for its unique patterns and warm color tones, travertine has become a popular choice for interior and exterior spaces. In recent years, a new innovation in the stone industry has emerged - cultured travertine. This artificial stone product replicates the look and feel of natural travertine while offering enhanced durability and versatility. In this comprehensive guide, we will explore the beauty and benefits of cultured travertine, its production process, applications, maintenance, and more.

Understanding Cultured Travertine

Cultured travertine, also known as engineered or manufactured travertine, is a man-made stone product designed to mimic the appearance of natural travertine. It is composed of a blend of natural materials such as limestone, marble, and other minerals, along with resins and pigments. The manufacturing process involves mixing these materials together to create a slurry that is then poured into molds to form tiles, slabs, or other custom shapes.

One of the key advantages of cultured travertine is its consistency in color and pattern. Unlike natural stone, which can vary in appearance due to geological factors, cultured travertine offers a uniform look that can be easily matched and replicated. This makes it an ideal choice for large-scale projects where consistency is important.

Benefits of Cultured Travertine

Cultured travertine offers a number of benefits that make it a popular choice for both residential and commercial applications. Some of the key advantages of cultured travertine include:

1. Durability: Cultured travertine is engineered to be more durable and resistant to stains, scratches, and etching compared to natural stone. This makes it an ideal choice for high-traffic areas such as kitchens, bathrooms, and commercial spaces.

2. Versatility: Cultured travertine can be customized to suit a wide range of design styles and preferences. It is available in various colors, finishes, and sizes, making it suitable for both traditional and contemporary settings.

3. Cost-Effective: Cultured travertine is generally more affordable than natural stone, making it a cost-effective alternative for homeowners and designers on a budget.

4. Easy Maintenance: Cultured travertine is easy to clean and maintain, requiring only regular sweeping and occasional sealing to keep it looking its best.

Applications of Cultured Travertine

Cultured travertine can be used in a variety of applications, both indoors and outdoors. Some common uses of cultured travertine include:

1. Flooring: Cultured travertine tiles are a popular choice for flooring due to their durability and timeless appeal. They can be installed in entryways, kitchens, bathrooms, and living areas to create a warm and inviting atmosphere.

2. Countertops: Cultured travertine countertops offer a luxurious look that can enhance the beauty of any kitchen or bathroom. They are heat-resistant and easy to clean, making them a practical choice for busy households.

3. Backsplashes: Roofing slate and environmental impact add a touch of elegance to kitchens and bathrooms. They are available in a variety of colors and patterns to complement any design scheme.

4. Wall Cladding: Cultured travertine can be used to create stunning accent walls or feature panels in residential and commercial spaces. Its natural beauty and texture add depth and character to any room.

5. Outdoor Spaces: Cultured travertine pavers are a popular choice for patios, pool decks, and outdoor walkways. They are slip-resistant and weather-resistant, making them ideal for outdoor use.

Production Process of Cultured Travertine

The production process of cultured travertine involves several steps to create a high-quality and consistent product. Here is an overview of the typical manufacturing process:

1. Raw Materials Selection: The first step in producing cultured travertine is selecting high-quality natural materials such as limestone, marble, and other minerals. These materials are crushed into a fine powder and carefully measured to ensure the correct proportions.

2. Mixing: The crushed materials are mixed together with resins, pigments, and other additives to create a slurry with a uniform consistency. The mixture is thoroughly blended to ensure a smooth and homogenous product.

3. Molding: The slurry is poured into molds that are shaped according to the desired size and thickness of the finished product. The molds are vibrated or pressed to remove air bubbles and ensure a dense and compact material.

4. Curing: The molded pieces are left to cure in a controlled environment for a specific period of time. This allows the materials to harden and bond together, forming a strong and durable product.

5. Finishing: Once the cultured travertine has cured, it is trimmed, polished, and finished to achieve the desired texture and appearance. The surface may be honed, polished, brushed, or tumbled to create different finishes.

6. Quality Control: Before the final product is packaged and shipped, it undergoes rigorous quality control checks to ensure that it meets the highest standards of consistency and durability.

Maintenance of Cultured Travertine

Proper maintenance is essential to preserve the beauty and longevity of cultured travertine surfaces. Here are some tips for caring for cultured travertine:

1. Regular Cleaning: Sweep or vacuum cultured travertine floors regularly to remove dirt and debris. Use a mild detergent or stone cleaner to mop the floors and wipe down countertops and other surfaces.

2. Sealing: Cultured travertine should be sealed periodically to protect it from stains and moisture. Consult with a professional to determine the appropriate sealer and sealing schedule for your specific application.

3. Avoid Harsh Chemicals: Avoid using harsh chemicals or abrasive cleaners on cultured travertine, as they can damage the surface and strip away the sealer. Opt for pH-neutral cleaners that are safe for use on natural stone.

4. Prevent Scratches: Place protective pads under furniture legs to prevent scratches on cultured travertine floors. Use cutting boards and trivets on countertops to avoid scratching or etching.

5. Address Stains Promptly: Clean up spills immediately to prevent staining on cultured travertine surfaces. Blot the spill with a clean cloth and rinse the area with water to remove any residue.

Conclusion

Cultured travertine offers a versatile and durable alternative to natural stone, with a wide range of applications in residential and commercial settings. Its beauty, consistency, and ease of maintenance make it a popular choice for homeowners, designers, and architects looking to achieve a timeless and elegant look. By understanding the production process, benefits, applications, and maintenance of cultured travertine, you can make an informed decision when choosing this innovative stone product for your next project.